Italeri 1/72 Sunderland I

| KIT #: | 1302 |

| PRICE: | £39-99 |

| DECALS: | Six options |

| REVIEWER: | Frank Reynolds |

| NOTES: | Eduard Masks CX 343 |

| HISTORY |

The

Short Sunderland represents the zenith of development of the British military

flying boat. It embodied the constructional and aerodynamic features of its

predecessor, the commercial C class boat from the same factory and was the first

RAF flying boat to have power operated turrets in the nose and tail. It was a

typical British design for a typically British purpose, intended to range far

over the oceans in support of a Navy that served a World-wide

Empire and be sufficiently self-contained that it could

represent British interests if the navy was not present. Such was the thinking

that still prevailed when the Sunderland commenced trials in 1938.

Having been

developed from a civil airliner design there was ample room in the bulbous hull

for the all the equipment associated with its military role, to the extent of

having unusual weapons racks that could be winched out under the inner wings for

the delivery of bombs or depth charges. Defensive armament initially consisted

of a single .303 machine gun in the bow turret, single hand-held .303s in each

of the beam gun positions and four .303s in the tail turret.

Having been

developed from a civil airliner design there was ample room in the bulbous hull

for the all the equipment associated with its military role, to the extent of

having unusual weapons racks that could be winched out under the inner wings for

the delivery of bombs or depth charges. Defensive armament initially consisted

of a single .303 machine gun in the bow turret, single hand-held .303s in each

of the beam gun positions and four .303s in the tail turret.

The

first production model the Mk.1 was powered by four Bristol Pegasus XXII

supercharged engines of 1,010 HP each. The typical cruising speed was 170mph

with a combat range of

1,750 miles. It was introduced into service with No 230

squadron in 1938 at Singapore, and 210 squadron at Pembroke Dock, Wales, swiftly

followed by Nos 204 and 228 Squadrons. The Sunderland was being rapidly

introduced into service at the outbreak of World War 2, with No 95, 101 and 270

squadrons. The aircraft first came to public prominence in September 1939 when

two aircraft from No 228 and 204 Squadrons rescued the entire crew of a

torpedoed merchant ship, the Kensington Court. On January 30 1940, the

Sunderland obtained its first U boat kill when an enemy vessel was scuttled

after attack by one of No 228 Squadron’s aircraft.

Seventy five Sunderland Is were built, before giving way on the production line

to the Mk.II, which flew in August 1941.

The

Sunderland was an outstanding machine of its time, rugged, reliable and

spacious. It could be operated independently for long periods of time and it had

a good record in suppressing and killing enemy submarines. It was not the

fastest or the best flying boat of World War 2, but it ranks among them.

A

Sunderland is preserved as a walk through exhibit in the Royal Air Force Museum

at Hendon, London. Although it is late war Mk V, it general layout is typical of

the breed and it demonstrates the fundamental differences between a flying boat

and land based maritime aircraft of the same period. The RAF Museum has neatly

arranged a tour that begins with access through the door in the side of the

forward hull portside and exits through the starboard side towards the tail.

Essence of shipping appears everywhere; there is an anchor, windlass, mooring

bollards and boat hooks. Much of the flooring consists of pierced metal grilles.

The crew has a galley and rest bunks. The midships bomb room is remarkable for

the fact that the bombs are suspended over the crew rest area. There is a small

workshop area with a bench and vice. The whole nose turret and fairing is

retracted to demonstrate how the crew can moor up to a buoy. It is a brilliant,

dramatic and evocative exhibit and the inspiration for this build.

| THE KIT |

Italeri’s offering is supplied in a glossy top opening box with a traditional

illustration of a Sunderland over a foaming sea and an exploding enemy

submarine. There are five parts frames in grey plastic, reasonably crisply

moulded and one of clear offering all of the transparencies and a plethora of

porthole windows. There is a rather thick fret of etched parts for small

details, the instrument panel and to detail the beaching gear. A sheet of good

quality Cartograf decals offers six options, all RAF aircraft, as follows.

No

210 Squadron, Oban Scotland, 1941. Camouflaged in Extra Dark Sea Grey and Dark

Slate Grey over Aluminium under surfaces.

No

210 Squadron Oban, 1940, camouflaged Dark Green and Dark Earth over Aluminium.

No 95

Squadron, Freetown, Sierra Leone, 1941 Grey and Green over Aluminium

No

204 Squadron, Bathhurst, Gambia 1941/42 Grey and Green over Sea Grey Medium.

No

230 Squadron, Eastern Mediterranean, 1940. Green and Earth over Night Black.

No

230 Squadron, Eastern Mediterranean, 1941, Grey and Green over Sky type S.

This is an

intelligent selection of colour schemes offering a choice of upper surfaces in

the early war emergency camouflage of Brown and Green upper surfaces or the

later type of sea camouflage in Grey and Green. Italeri have also covered four

different under surface colours in Aluminium, Medium Grey, Black and Sky. Four

of the aircraft feature the upper surface camouflage wrapped around under the

rear fuselage boom. Six colour side profiles are set out on the box tray. This

range of options was to cause me some self-inflicted problems as the result of

brain freeze, as noted below.

This is an

intelligent selection of colour schemes offering a choice of upper surfaces in

the early war emergency camouflage of Brown and Green upper surfaces or the

later type of sea camouflage in Grey and Green. Italeri have also covered four

different under surface colours in Aluminium, Medium Grey, Black and Sky. Four

of the aircraft feature the upper surface camouflage wrapped around under the

rear fuselage boom. Six colour side profiles are set out on the box tray. This

range of options was to cause me some self-inflicted problems as the result of

brain freeze, as noted below.

The

kit is one of Italeri’s deluxe packages that includes the etch, as noted, the

good choice of colour finishes and a 24 page detailed reference manual with a

selection of photographs and sketches. This useful manual has photos which

contradict Italeri’s interpretation of this big boat’s surface detail since the

real thing is remarkably smooth in appearance

Assembly instructions consist of a 20 page A4 booklet in greyscale, setting out

24 stages of construction and finishing, with CGI rendered exploded views.

Colour call outs give FS numbers, Model Master paints or Italeri’s own.

Surface detailing on the main parts, the wings, fuselage and tail, is heavy,

obvious and quite dramatic, with quite deeply engraved panel lines. There are

few kits in my experience that exhibit this extreme of detailing, it is almost

in low relief. Each hull panel is edged with tiny engraved rivets and the upper

surface of the wing appears quilted from certain angles. There has been some

dramatic discussion on the web about whether this is acceptable or renders the

kit “unbuildable” and it is certainly more than I would choose, but for the

purposes of this review I have left it “as is”.

| CONSTRUCTION |

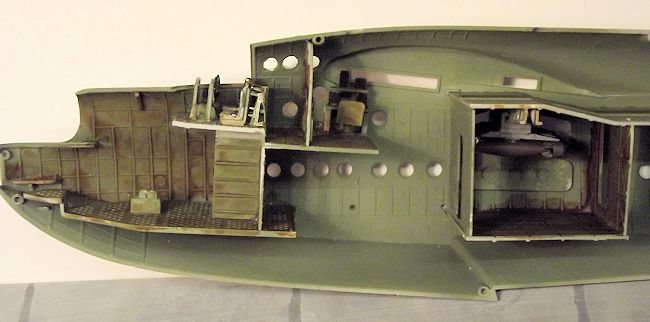

This

is one kit that benefits from a careful read-through of the assembly

instructions and a degree of pre-planning. The interior provides three separate

cabin areas, with appropriate bulkheads, arranged around those parts of the

interior that might be seen through the various openings in the hull. So

construction begins with the interior, the majority of which I airbrushed in

Xtracrylix XA1010 (British) Aircraft Grey-Green. The main flight deck consists

of a stepped floor with a bulkhead to the navigator/engineer’s position. The

main instrument panel can be optionally built with an etch instrument panel or

the kit decal that I used. Etch seat belts are provided for the two pilot’s

seats, together with rudder pedals. Two control wheels are fixed to convincing

pedestals and the seats have a rear framework of folded pierced etch. The rear

bulkhead has a moulded in folded curtain across the

doorway to

the rear cabin that contain the radio operator’s position and two further

decal-type instrument panels. This is all built as a sub-assembly that sits on

top of the lower forward compartment, which consists of a pierced floor with a

rear bulkhead and centre staircase that leads to the flight deck. Assembly of

these units certainly emphasise the “upstairs-downstairs” nature of the bulky

Sunderland. An anchor and hawser is provided for those who wish to decorate this

area together with a boat hook.

doorway to

the rear cabin that contain the radio operator’s position and two further

decal-type instrument panels. This is all built as a sub-assembly that sits on

top of the lower forward compartment, which consists of a pierced floor with a

rear bulkhead and centre staircase that leads to the flight deck. Assembly of

these units certainly emphasise the “upstairs-downstairs” nature of the bulky

Sunderland. An anchor and hawser is provided for those who wish to decorate this

area together with a boat hook.

The

instructions next invite you to glue some 35 pieces of glazing to the portholes.

I had already planned to make this glazing from Micro Kristal Klear after the

painting stage, so the injected items were discarded. Two large panels are

provided to cover the openings to the bomb room, located under the centre

section. I fixed these as retracted inside the hull for deployment of the

weapons.

The

nose compartment sub assembly was glued into the right fuselage half and

attention turned to the next major interior structure.

There

is a cranked floor to the upper fuselage section, below which is a floor, with

front and rear bulkheads to form the bomb room/ crew accommodation. Two rails

are moulded in to accommodate the bomb racks when the armament is stowed

internally. This unit was glued into the right fuselage half. This was a

convenient time to assemble the bomb racks so that one set could be fixed

internally leaving the other to be added externally towards the end of the

build. The underwing bomb racks are a mixture of plastic and etch parts which

are assembled with plastic glue and cyano. Eight bombs are provided as the sole

offensive armament and were painted Olive Drab. The interior was given a

weathering wash of water based Dark Brown paint from the Games Workshop range.

The crew doors to the fuselage nose and amidships were glued shut.

Attention

now turns to the components that must be trapped between the fuselage halves

when they are closed up, being the nose and tail turrets and the fight deck

glazing. The turrets are small with complex curves and multiple glazing panels.

The Eduard pre-cut paint masks are indispensable for this stage. Each turret

consists of a base with side trunnions to support the guns and a support hoop

over the gunner’s seat back. All of the interior parts were painted in

Grey-Green and the guns picked out in Tamiya XF-56 Metallic Grey. Eduard provide

some 42 tiny masks for the turrets and some 20 for the flight deck, and this

provided a happy evening’s eye strain in their application but the result was

well worth it. Both turrets were airbrushed in Xtracrylix XA 1025 RAF Dark Slate

Grey and when dry the nose turret was fixed into the similarly pre-painted

retractable nose fairing. The flight deck glazing is provided with a

roof-mounted internal throttle box which is painted Black with relief detail

picked out in dry brushed Silver.

Attention

now turns to the components that must be trapped between the fuselage halves

when they are closed up, being the nose and tail turrets and the fight deck

glazing. The turrets are small with complex curves and multiple glazing panels.

The Eduard pre-cut paint masks are indispensable for this stage. Each turret

consists of a base with side trunnions to support the guns and a support hoop

over the gunner’s seat back. All of the interior parts were painted in

Grey-Green and the guns picked out in Tamiya XF-56 Metallic Grey. Eduard provide

some 42 tiny masks for the turrets and some 20 for the flight deck, and this

provided a happy evening’s eye strain in their application but the result was

well worth it. Both turrets were airbrushed in Xtracrylix XA 1025 RAF Dark Slate

Grey and when dry the nose turret was fixed into the similarly pre-painted

retractable nose fairing. The flight deck glazing is provided with a

roof-mounted internal throttle box which is painted Black with relief detail

picked out in dry brushed Silver.

The

nose turret assembly and the rear turret were fixed into the right hand fuselage

half followed by the flight deck glazing. This glazing has an unusual flange

moulded to its joining edges, with the result that it cannot be added after the

fuselage is closed up. The two main fuselage halves were glued together after

some trimming and fettling to the edges of the internal floors and bulkheads in

order to get the parts to close up snugly. The tall tail fin is has one half

moulded onto the right fuselage half but the left side is a separate panel that

can be added while trapping the rudder in place. The manner of construction

means that the turrets’ gun barrels are vulnerable to breakage throughout the

rest of the build.

This

large assembly was set aside to settle for a couple of days while attention

turned to the wing and tail components, which are essentially simple. Each wing

consists of one each upper and lower halves with the engine nacelles moulded in.

Marked holes need to be drilled out for the float rigging. The large ailerons

consist of upper and lower sections that are trapped between the wing sections.

There are no separate flaps. The

port

wing is provided with a pair of clear glazed landing lights in the leading edge,

but, having gone to the trouble of providing this feature, Italeri has not

extended this detail to the wing tip navigation lights, which are simply scribed

on the solid plastic wing tips. Each wing has an inset rail

for the

bomb carriers to slide into the launch position but I decided to add these later

at the finishing stage, together with the remaining bomb carrier sub assembly.

for the

bomb carriers to slide into the launch position but I decided to add these later

at the finishing stage, together with the remaining bomb carrier sub assembly.

The

tail section consists simply of upper and lower panels to the fixed sections and

elevator structures, these fit positively into stubs on the rear fuselage.

Italeri next suggests that the beaching gear is attached. I assembled it,

together with the tail trolley, but postponed its attachment to the airframe

until much later in the build. The main beaching gear consists of a massive

vertical leg, moulded in two halves to incorporate the flotation collar. Twin

single piece wheels are provided. The legs were painted in medium grey with the

flotation collars picked out in red brown, the wheels silver with tyres finished

in Tamiya’s XF-85 Rubber Black. The tail trolley was a little more complex being

a box and lid arrangement with a built in towing hook. To this, two “v” shape

cradles are attached with angled etch plates to support the hull sides. Two

single part wheels complete the assembly. The trolley was painted flat red with

the hull support pads picked out in red brown.

The

wing is glued to the fuselage stubs via positive fittings tongues to form a

relatively large and heavy basic airframe. Some filler was necessary along the

joint between the fuselage halves. I used Squadron Green Putty which sets

quickly and after it dried small areas of the engraved panels lined were

rescribed.

The

engines and nacelles were built up next. The single row radial engines have

reasonable cylinder detail but care must be taken when cutting them from the

parts frames, since alternate cylinders have a small pip moulded onto the end,

which are spacers to locate the engine cowlings. The collector rings to the cowl

fronts are moulded separately so they can be painted in metallic bronze and

added after the cowls are assembled and painted. The engines were painted

metallic grey and detailed with a wash of dirty thinners. Care must be taken in

fitting the cowls around the radial engines since the joining pins provide

minimal contact area and the cowls must be correct aligned for the exhausts; the

kit instructions make this clear.

The

wing floats were assembled ready for the painting stage. The floats are moulded

in two halves and the support struts are provided with a good strong

self-aligning socket and peg arrangement. As a precaution, I checked the struts

for fit into the underwing sockets while the glue was setting.

| COLORS & MARKINGS |

Next

I screwed up the paintwork by confusing my choice of a paint finish. I had

airbrushed the upper surface base camouflage, in Dark Slate Grey from the

Xtracrylix range with the upper surface colours carried under the rear fuselage

boom, combined with Medium Sea Grey under surfaces. I then discovered that there

was no such combination on the decal options offered, so I had to undertake a

partial repaint, starting by re-spraying the lower surfaces in Tamiya XF-16 Flat

Aluminium. The under surfaces were then covered with masking tape and the

original Slate Grey to the top surfaces touched in.

The top surface

was then carefully masked out, using Blu Tack “sausages” and an infill of

masking tape to define the demarcation between the upper surface colours before

adding the shadow shaded area of Extra Dark Sea Grey. With the size of the

fuselage and wing components this took a lot of the low tack putty and tape.

When

I came to strip off the masking the camo colours had not taken too well to the

silver overspray on the fuselage sides and small ragged areas of the Grey and

Green were pulled away when the tape was removed. I also found that the paint

along the lower hull chipped when scratched with a finger nail. Strangely, I had

accidentally created an interpretation of the paint damage to be found along the

waterline of a well-used flying boat, so I decided to leave it as it was. The

same had happened to the wing floats, so at least I had consistency. I consider

this the happy result of a special modelling system known as SRSU (the Self

Rectifying Screw Up). The paintwork was sealed with two brushed coats of Future/Klear

floor polish in preparation for the decals.

By

default I had ended up with the colour scheme for an aircraft of No.95 Sqn.,

Royal Air Force, Freetown, Sierra Leone, 1941. But it was none the worse for

that. The Cartograf

decals went on easily

and

responded well to Micro Sol and Micro Set, necessary in view of the heavily

detailed exterior. The decals simply provided national markings, squadron codes

letters and the aircraft serial number. A small decal is provided for the gas

detection patch on the fuselage nose.

and

responded well to Micro Sol and Micro Set, necessary in view of the heavily

detailed exterior. The decals simply provided national markings, squadron codes

letters and the aircraft serial number. A small decal is provided for the gas

detection patch on the fuselage nose.

| FINAL CONSTRUCTION |

The

chunky beaching gear was glued in place and the main legs have positive

locations in the fuselage sides. This was left overnight to set.

The

airframe was propped upside down to permit rigging of the floats. Small marked

holes in the floats and wing undersides were drilled out to accept the bracing

wires. Italeri charmingly invites the modeller to “add wire bracings from

stirred plastic” which I take to mean stretched sprue. However I elected to use

Griffon Model 0.3mm Brass Hollow Pipe, marked out with dividers and cut slightly

overlong to enable it to be juggled into the fixing holes before being secured

with a tiny drop of superglue. The pipe/rigging wire was painted in enamel matt

silver before installation. Although I normally use acrylics, the enamel had

better adhesion. This rigging method was new to me and recommended by a fellow

modeller, Rich Reynolds, who happens to be my son. The relatively stiff hollow

wire is easy to handle and provides a rigid assembly, so it is a method that I

shall return to with future projects.

The

airframe was propped upside down to permit rigging of the floats. Small marked

holes in the floats and wing undersides were drilled out to accept the bracing

wires. Italeri charmingly invites the modeller to “add wire bracings from

stirred plastic” which I take to mean stretched sprue. However I elected to use

Griffon Model 0.3mm Brass Hollow Pipe, marked out with dividers and cut slightly

overlong to enable it to be juggled into the fixing holes before being secured

with a tiny drop of superglue. The pipe/rigging wire was painted in enamel matt

silver before installation. Although I normally use acrylics, the enamel had

better adhesion. This rigging method was new to me and recommended by a fellow

modeller, Rich Reynolds, who happens to be my son. The relatively stiff hollow

wire is easy to handle and provides a rigid assembly, so it is a method that I

shall return to with future projects.

Construction was completed with the installation of aerials and the astrodome to

the upper fuselage and the beam guns with their extended wind deflectors. The

second bomb rack was fixed in the run out position under the

port

wing to give a little variety to the weapons layout.

| CONCLUSIONS |

I do not

consider that the etch fret of parts adds much to the model since the metal is

rather thick and most of the etch

could equally well have been rendered in plastic. The decal sheet is adequate

but the

absence of any airframe stencilling is disappointing in a kit that is marketed

and priced as having premium features. The coloured booklet is helpful but again

does not really tip the balance in favour of the relatively high price.

I do not

consider that the etch fret of parts adds much to the model since the metal is

rather thick and most of the etch

could equally well have been rendered in plastic. The decal sheet is adequate

but the

absence of any airframe stencilling is disappointing in a kit that is marketed

and priced as having premium features. The coloured booklet is helpful but again

does not really tip the balance in favour of the relatively high price.

This

is a typical Italeri kit in that the fit of parts is adequate rather than

totally precise. As to the surface detail, I would not consider this kit to be

“unbuildable” but the designers should perhaps have had a closer look at the

photographs that are provided with this kit to get a better feel for the

characteristics of the external skinning.

It is

nigh on fifty years since Airfix first brought a 1:72 Sunderland to the market

place and Italeri should be congratulated on a large and imposing model. It

looks the part, in my opinion.

| REFERENCES |

Warplanes of the Second World War, Volume Five, Flying Boats, by William Green.

Macdonald

1961.

The

Short Sunderland, by Geoffrey Norris and Richard Ward, Profile Publications

Ltd., 1967

Frank

Reynolds

October 2014

Kit

from my LHS, Spot on Models and Hobbies of Swindon, England.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.