|

KIT: |

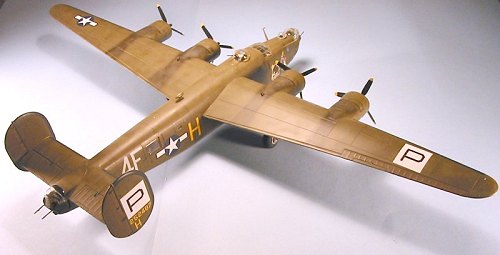

Monogram 1/48 B-24J Liberator |

|

KIT # |

? |

|

PRICE: |

$ Currently (Oct 2003) OOP |

|

DECALS: |

one option |

|

REVIEWER: |

|

|

NOTES: |

Aeromaster decals used. |

|

HISTORY |

I remember an old B-24 navigator I used to fly Stearmans with in Sacramento 26 years ago, once telling me about combat in the European theater: "There we were, plodding along at 20,000 feet, right in the middle of the flak, getting the crap shot out of us, and there were those damned B-17s at 26,000 feet, flying along above it."

The Consolidated B-24 Liberator was built in larger numbers than any other heavy bomber used by any combatant of the Second World War, with 18,188 Liberators built between June 1941 and May 31, 1945, when the last production line was shut down. It served with more air forces than the B-17, it had a greater range, and a greater load-carrying capability. Yet the B-17 is considered one of the truly "immortal" aircraft of the Second World War, while the B-24 served its entire career in the shadow of the B-17, as my old friend remembered. Within months of the end of the war, the Liberator left the active Air Force as quickly as units could be deactivated and the airplanes flown to the boneyards.

Compared to

the aesthetically superb B-17, the Liberator was an ugly duckling, with

its slab-sided fuselage and barn-door vertical stabilizers. While

compared with the Fortress historically, the Liberator actually came from

a later generation of design and technology, and came to life

specifically as the result of an Air Force specification for a bomber

with superior performance to the B-17, with a speed of 300 m.p.h., range

of 3,000 miles, and ceiling of 35,000 feet. With a wartime load of armor

and defensive armament, the combat-ready B-24 did not meet these

requirements, but it was so much better than the B-17 on every

specification other than ability to absorb punishment far beyond design

specifications - one never sees photographs of B-24s that returned to

base with their nose blown off, or the rear fuselage nearly severed by a

mid-air-collision with a Bf-109 - that it ended up serving with the U.S.

Navy, the RAF, the RAAF, RCAF and the SAAF, in every theater in which

Allied air forces were committed. The B-24 was largely responsible for

winning the Battle of the Atlantic (along with the introduction of the

escort carrier), as the first anti-submarine aircraft with a range

capable of plugging the "Atlantic Gap" where the U-boats scored their

greatest victories. It replaced the B-17 completely in the Pacific, due

to its longer range and greater load-carrying capability. The B-17 could

never have carried out "Operation Tidal Wave," the great Ploesti raid

flown from North Africa on August 1, 1943,

Compared to

the aesthetically superb B-17, the Liberator was an ugly duckling, with

its slab-sided fuselage and barn-door vertical stabilizers. While

compared with the Fortress historically, the Liberator actually came from

a later generation of design and technology, and came to life

specifically as the result of an Air Force specification for a bomber

with superior performance to the B-17, with a speed of 300 m.p.h., range

of 3,000 miles, and ceiling of 35,000 feet. With a wartime load of armor

and defensive armament, the combat-ready B-24 did not meet these

requirements, but it was so much better than the B-17 on every

specification other than ability to absorb punishment far beyond design

specifications - one never sees photographs of B-24s that returned to

base with their nose blown off, or the rear fuselage nearly severed by a

mid-air-collision with a Bf-109 - that it ended up serving with the U.S.

Navy, the RAF, the RAAF, RCAF and the SAAF, in every theater in which

Allied air forces were committed. The B-24 was largely responsible for

winning the Battle of the Atlantic (along with the introduction of the

escort carrier), as the first anti-submarine aircraft with a range

capable of plugging the "Atlantic Gap" where the U-boats scored their

greatest victories. It replaced the B-17 completely in the Pacific, due

to its longer range and greater load-carrying capability. The B-17 could

never have carried out "Operation Tidal Wave," the great Ploesti raid

flown from North Africa on August 1, 1943,

The Consolidated Model 32 was designed around the Davis high-life airfoil, which offered 25 percent less profile drag at low speed and 10 percent less at high speed, than conventional airfoils. While the Liberator's wing would be dirtied-up with various excrescences associated with a very non-aerodynamic landing gear installation, the value of the Davis wing can be seen from the fact that once the Liberator flew, Boeing designed the B-29 around the same wing.

The first

combat-worthy Liberator was the B-24D, 2,425 of which were built by

Consolidated in San Diego, and 303 by Consolidated Fort Worth, with an

additional 10 by Douglas at Tulsa. With the outbreak of war in December,

1941, Ford Motor Company was brought into Liberator production, using the

world's largest factory at Willow Run, where production ultimately hit

stride at 200 aircraft per month with the B-24J.

The first

combat-worthy Liberator was the B-24D, 2,425 of which were built by

Consolidated in San Diego, and 303 by Consolidated Fort Worth, with an

additional 10 by Douglas at Tulsa. With the outbreak of war in December,

1941, Ford Motor Company was brought into Liberator production, using the

world's largest factory at Willow Run, where production ultimately hit

stride at 200 aircraft per month with the B-24J.

By 1943, the Liberator was in production at Consolidated Aircraft in San Diego and Fort Worth, Douglas at Tulsa and Dallas, and Ford at Willow Run, Michigan. Combat experience had shown the airplane needed additional forward armament. In the Pacific, technicians of the 5th Air Force operating under the leadership of "Pappy" Gunn had come up with a new nose that utilized the same tail turret in a different nose. In late 1943, this field modification showed up on the production line as the B-24H, utilizing an Emerson turret. 738 Hs were built by Consolidated Fort Worth, with an additional 1,780 built by Ford and 582 by Douglas. Production hit its stride with the 6,678 B-24Js built by the five contractors starting in January 1944.

By September

1944, the USAAF had an operational strength of 6,043 B-24s, equipping 45

Bomb Groups world-wide. Liberators provided all the heavy-bombing

capability in the Pacific prior to the introduction of the B-29, and were

the majority bomber of the 15th Air Force that operated from Italy.

Only in the 8th Air Force was the Liberator in the minority. Four

B-24 groups of the Second Air Division of the Eighth were re-equipped

with B-17s in June and July 1944, so that the 1st and 2nd Air Divisions

were totally B-17-equipped, with the 3rd Air Division flying B-24s.

In part, this recognized the nature of

the air war over

Northern Europe, which was the "main front" of the combined bomber

offensive and faced the greatest opposition from the Luftwaffe. The

high-altitude capability of the Fortress, and its ability to survive

heavy damage, outweighed its comparatively light bomb load of only 4,000

lbs. The all-up weight of 71,400 lbs of the B-24J had only served

to worsen its flying characteristics, while the B-17 was considered a

more stable bombing platform.

the air war over

Northern Europe, which was the "main front" of the combined bomber

offensive and faced the greatest opposition from the Luftwaffe. The

high-altitude capability of the Fortress, and its ability to survive

heavy damage, outweighed its comparatively light bomb load of only 4,000

lbs. The all-up weight of 71,400 lbs of the B-24J had only served

to worsen its flying characteristics, while the B-17 was considered a

more stable bombing platform.

In retrospect, apart from a production record no other airplane will ever come close to, the B-24 insured its place in history by flying missions no other bomber could accomplish, be it the longest-range bombing mission flown before the advent of the B-29 (the August 1943 Ploesti raid), closing the Atlantic Gap, or flying fuel to China for the B-29s. The Liberator delivered bombs, depth charges, gasoline, freight, troops and V.I.P.s, establishing a record that - when examined in detail - is truly second to none, proving decisively that "ugly is as ugly does."

|

THE KIT |

As I recall, the B-24J Liberator - the first Liberator model released by Monogram - came out no later than 1977, inasmuch as I built a model from it for a boss who had flown them in that year. In the late 1970s or early 1980s, the kit was re-released as the earlier "glass nose" B-24D, and releases in the years since have alternated between the two releases, both of which are currently out of production.

Modelers who

have never been around real airplanes close enough to actually touch them

claim that the kit is "out of date," since it doesn't have the now de

rigueur "engraved panel lines." Never mind that engraved panel lines as

a rule are actually more inaccurate than the old raised panel lines,

never further mind the fact that the Liberator was constructed with

lapped panels, so that the raised panel line detail indeed looks more

"right." What's needed is a new "state of the art" Tamiya kit at a

retail price of $150, to satisfy those without the hand-eye coordination

to apply putty to a seam line.

Modelers who

have never been around real airplanes close enough to actually touch them

claim that the kit is "out of date," since it doesn't have the now de

rigueur "engraved panel lines." Never mind that engraved panel lines as

a rule are actually more inaccurate than the old raised panel lines,

never further mind the fact that the Liberator was constructed with

lapped panels, so that the raised panel line detail indeed looks more

"right." What's needed is a new "state of the art" Tamiya kit at a

retail price of $150, to satisfy those without the hand-eye coordination

to apply putty to a seam line.

In fact, with an ever-so-slight application of "some modeling ability required" the Monogram B-24 can be built out of the box with nothing more than some Mr. Surfacer 500 along some seams, without harming the panel lines. And no other model company is going to release a kit of this airplane at a price less than $20, which is the general price of this kit.

Numerous aftermarket decal sheets exist for the Liberator, which allows a modeler to have a good time building a good model of an important airplane. My only regret is that no one has ever done "Witchcraft," the most successful American bomber of World War II, which carried her five crews through 137 missions between February 1944 and V-E Day, without a single abort. I'll re-do this model in a hot New York Minute the day I get those markings.

|

CONSTRUCTION |

Yes, this kit comes from the days when parts fit was not what one finds today upon opening a Tamiya or Hasegawa kit, but with a bit of care and pre-fitting of parts before adding glue, a modeler will find themselves only using putty in a few places, with Mr. Surfacer 500 taking care of other seams and joints in such a way that a minimum of the raised detail will be lost.

There is not a

lot of interior provided, but what is there is more than sufficient if

you use the kit glass. I tried using the Koster vacuformed turrets, but

multiple-part turrets made from thin clear plastic do not make up that

easily into useable turrets; in the end, I managed to use the nose and

tail turrets from the kit, after Futuring the two halves and then joining

them with Micro Kyrstal Klear white glue, which became invisible and did

not crazy the plastic joint as would have been the case had I glued the

turret halves together with Ambroid Super Weld or any other plastic

cement.

There is not a

lot of interior provided, but what is there is more than sufficient if

you use the kit glass. I tried using the Koster vacuformed turrets, but

multiple-part turrets made from thin clear plastic do not make up that

easily into useable turrets; in the end, I managed to use the nose and

tail turrets from the kit, after Futuring the two halves and then joining

them with Micro Kyrstal Klear white glue, which became invisible and did

not crazy the plastic joint as would have been the case had I glued the

turret halves together with Ambroid Super Weld or any other plastic

cement.

I painted the cockpit and nose area in Bronze Green, using Gunze-Sangyo Medium Green F.S.34079, which is "close enough." The rear fuselage was painted with Tamiya yellow zinc chromate. With a wash of Tamiya "Smoke" to pop out detail, and painting the black boxes and instrument panels, etc., I managed to do an interior that was good enough for my purposes. A modeler could indeed do a lot more detailing of the interior, particularly the bomb bay and the area around the waist guns, were they so inclined.

I assembled

the fuselage, and left the bomb bay doors off, so that I could pour

sufficient fishweights down the lower nose beneath the cockpit floor once

the model was assembled and I could figure the weight. Approximately 55%

of the fuselage, with the tail, is aft of the main gear, which makes the

model a severe tail-sitter. Alternatively, you can leave the lower rear

hatch open and glue in a boarding ladder, which will prop up the tail.

Careful assembly along the centerline resulted in my only having to apply

a single coat of Mr. Surfacer 500 to get rid of that seam. By pressing

the rudders tight to the horizontal stabilizer when applying the Ambroid

Super Weld, and by repeating that process when gluing the tail assembly

to the fuselage, I managed to lose most of the gaps

and was able to take

care of the gap where the lower surface of the horizontal stabilizer

joins to the fuselage with some CA glue left in the gap to dry

"naturally."

and was able to take

care of the gap where the lower surface of the horizontal stabilizer

joins to the fuselage with some CA glue left in the gap to dry

"naturally."

The wings assemble easily, but there is going to be some serious seams to be filled along either side of both engine cowlings, and the gap when the front of the cowling with the engine is glued in place. I hit the seams with CA glue and accelerator, then sanded them smooth, applied Mr. Surfacer 500, and got a good-looking result which only needed a bit of rescribing of panel line detail.

Once the wings were glued to the fuselage, I began pouring fish weights into the nose until the model tilted nose-down while being held at the main gear plug. This took about an entire bag of weights, some 22 little quarter-inch balls, to accomplish.

|

CAMOUFLAGE & MARKINGS |

Painting:

Painting:

I first went over all the seams with light grey to be sure I had gotten them completely. Sure enough, I hadn't. A ran CA glue into the little gaps, hit it with accelerator, and broke out the sanding sticks. Another coat of grey revealed I had achieved the goal. I then pre-shaded the model with flat black over the panel lines, and also painted the leading edges of the flying surfaces for the de-icer boots. When that was dry I masked off the de-icer boots.

The underside

was painted with Tamiya Neutral Grey, with the upper surfaces done with

Gunze Sangyo Olive Drab 1 and Olive Drab 2, which are different tones of

OD and give a good base to start fading. Since these airplanes operated

in northern Europe where they were mostly under cloud cover on the

ground, I added in some Gunze-Sangyo Violet for some of the panel fading,

in order to simulate UV effect, then added

in a bit of yellow to go over

the fabric control surfaces. The entire effect is quite muted and looks

accurate in person. When all was dry, the de-icer boots were unmasked

and the model was given two coats of Future.

in a bit of yellow to go over

the fabric control surfaces. The entire effect is quite muted and looks

accurate in person. When all was dry, the de-icer boots were unmasked

and the model was given two coats of Future.

Decals:

The model is done as "Blasted Event," a B-24J of the 487th Bomb Group, which entered combat from England in April 1944, as part of the Second Bomb Division, which was equipped two-thirds with B-17 groups and one-third with B-24 groups. Due to the performance dissimilarities between the two types, Eighth Air Force ordered the B-24 groups to re-equip with B-17s in June and July 1944. The 487th said good-bye to their Liberators in July.

|

FINAL CONSTRUCTION |

After the decals were fully set and I had applied another coat of Future over everything, I applied two coats of thinned Dullcote, then applied the exhaust stains with Tamiya "Smoke," after which I applied another thin coat of Dullcote to flatten down the too-glossy "Smoke."

I then attached the landing gear and the nose, tail, and dorsal turrets, and the propellers.

|

CONCLUSIONS |

It is highly

unlikely anyone is going to release a "state of the art" B-24 or B-17,

since such kits would cost well over $100 nowadays. The Monogram B-24

can be found on dealer's tables at model shows for $20 or less, and is

excellent value for the money. The kit is not difficult to build, and

makes up into an impressive model. Those who say it isn't "state of the

art" and therefore somehow "unworthy" of being included in a collection

reveal their own ignorance. The Liberator was an important element in

the Allied arsenal that brought victory over fascism, and represents the

courage of thousands of young men who trusted themselves to it, just as

does the B-17 and the Lancaster. If you just gotta do it "better," Bill

Koster provides a kit of different turrets and noses that allow you to do

the B-24H, the B-24M with the manual tail turret, and the Navy PB4Y-1

with the Erco nose turret. What ever version you choose, the kit is an

enjoyable project that will benefit from an application of skill.

It is highly

unlikely anyone is going to release a "state of the art" B-24 or B-17,

since such kits would cost well over $100 nowadays. The Monogram B-24

can be found on dealer's tables at model shows for $20 or less, and is

excellent value for the money. The kit is not difficult to build, and

makes up into an impressive model. Those who say it isn't "state of the

art" and therefore somehow "unworthy" of being included in a collection

reveal their own ignorance. The Liberator was an important element in

the Allied arsenal that brought victory over fascism, and represents the

courage of thousands of young men who trusted themselves to it, just as

does the B-17 and the Lancaster. If you just gotta do it "better," Bill

Koster provides a kit of different turrets and noses that allow you to do

the B-24H, the B-24M with the manual tail turret, and the Navy PB4Y-1

with the Erco nose turret. What ever version you choose, the kit is an

enjoyable project that will benefit from an application of skill.

October 2003

Review kit courtesy my wallet.

If you would like your product reviewed fairly and quickly by a site that has over 200,000 visitors a month, please contact me or see other details in the Note to Contributors.