Vac Wings 1/72 Antonov A-7 Glider

| KIT #: | ? |

| PRICE: | $10.00 |

| DECALS: | None |

| REVIEWER: | Carmel J. Attard |

| NOTES: | A vac form kit, no decals issued. |

| HISTORY |

The A-7 was an

assault glider that was for a time obscure to Western observers and historians.

It was an important Soviet glider and as such deserves its place in history. The

A-7 was announced in December 1940 in a design competition for an assault

glider. Also known as the RF-8 in the Red Front series of gliders for the Soviet

Air Force, it was designed by Oleg K. Antonov and after it was declared the

winner of a design for military transport gliders it became the prototype for

the subsequent A-7. The A-7

was to be the first Soviet transport glider to

achieve production status. The assembly plant was in

was to be the first Soviet transport glider to

achieve production status. The assembly plant was in

The A-7 was a

remarkable clean design, all-wood construction with partial fabric covering on

wing areas and tail-planes. The core of the structure was the fuselage, which

was almost of the pod and boom type with an enclosed cockpit and accommodation

for a maximum of 9 troops in virtually windowless compartment. There were two

pairs of double doors; one was forward on the port side and the other aft on

starboard side. The tailskid landing gear included manually operated retractable

main units, stowed in wells in the lower fuselage sides.

The standard tug was

the Tupolev SB-2, Ilyushin DB3 or the Il-4. The maximum towing speed was a high

300Km/h. The A-7 saw limited service behind German lines in WWII and was used

primarily to supply or land partisans or sabotage groups. Itís best known action

was the supply flights to the

| THE KIT |

The A-7 is a vac-form

kit molded on a single sheet of white styrene and a small clear part for the

canopy. Issued by Vac Wings 72 of

The A-7 is a vac-form

kit molded on a single sheet of white styrene and a small clear part for the

canopy. Issued by Vac Wings 72 of

| CONSTRUCTION |

The kit contains

around 19-vacform parts and one clear part for the cockpit canopy in case one

desires to use it, and this has clear frame detail on it. The kit fuselage and

wing parts also have fine surface detail. Construction follows the now standard

adopted for vacform kits. Each part is first lightly scored around on the single

sheet using X-acto blade, which is then snapped from the sheet. Fuselage and

wing parts are sanded perfectly flat so that the edges mate. A 400 wet and dry

sand paper tape mounted (double sided) to a piece plate glass for a smooth

surface. Pieces are trial fit together before affixing with liquid glue. Parts

are checked with plans issued. With the exception of the rudder and tail-planes

all the other items matched with the drawings.

The kit contains

around 19-vacform parts and one clear part for the cockpit canopy in case one

desires to use it, and this has clear frame detail on it. The kit fuselage and

wing parts also have fine surface detail. Construction follows the now standard

adopted for vacform kits. Each part is first lightly scored around on the single

sheet using X-acto blade, which is then snapped from the sheet. Fuselage and

wing parts are sanded perfectly flat so that the edges mate. A 400 wet and dry

sand paper tape mounted (double sided) to a piece plate glass for a smooth

surface. Pieces are trial fit together before affixing with liquid glue. Parts

are checked with plans issued. With the exception of the rudder and tail-planes

all the other items matched with the drawings.

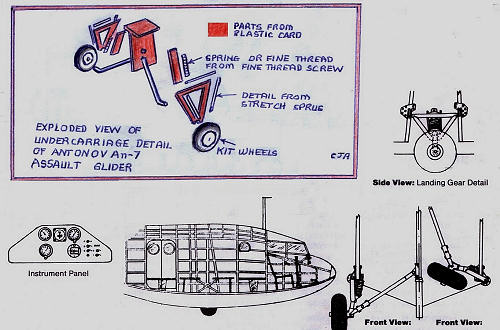

The rudder needed an

extension of 3mm at the rear which was a gradual addition making a bigger rudder

area. This is best done by tracing the rudder on a 0.4mm plastic card that is

then inserted between the kit fuselage parts at the rudder area and fair with

filler at the stepped rear. 7 round windows and 2 semi circular ones were

drilled and shaped to conform with the drawings given, these were at side of

fuselage, under the fuselage, and one on the roof. The forward crew area was

built up from the kit parts and a floor area for the passenger section was made

from plastic card that was then inserted inside the fuselage compartment. A

bulkhead separated the two co mpartments. 4 double bench seats at sides and two

single bench seats at center of fuselage were added inside the passenger area

while a pilot seat, rudder pedals, control stick and instrument panel added to

the front compartment. Close study of the landing gear detail indicated the

position of the retractable undercarriage bay and its function. This required

opening two rectangular panels under the fuselage and adding a central dividing

wall, which secured the undercarriage legs. The drawing I made shows in

simplified detail of how I built it from kit wheels, plastic card, spring/thread

and other detail from stretch sprue.

mpartments. 4 double bench seats at sides and two

single bench seats at center of fuselage were added inside the passenger area

while a pilot seat, rudder pedals, control stick and instrument panel added to

the front compartment. Close study of the landing gear detail indicated the

position of the retractable undercarriage bay and its function. This required

opening two rectangular panels under the fuselage and adding a central dividing

wall, which secured the undercarriage legs. The drawing I made shows in

simplified detail of how I built it from kit wheels, plastic card, spring/thread

and other detail from stretch sprue.

The wing parts also had the flaps separated, which were then assembled, in partially lowered position. The tail planes were extended by 3mm in order to match them with drawing and ensuring that the elevator parting was 90 degrees to the axis of the fuselage when attached to it. Aerial mast and rudder ballast were made from metal pins cut to size and fixed with super glue. As for the canopy, I decided to put away the one issued and as the window apertures were small I carefully cut and shaped these with a sharp-pointed Exacto blade and needle files so that Kristal Kleer could make the glazing. A front eyehole for tying the tug cable was made from a small piece of bent wire.

| COLORS & MARKINGS |

The operational

camouflage was olive green and dark earth camouflage to all upper surfaces and

pale blue underside. The camouflage had feathered edges. For night operations

the undersurfaces were matt black and were without wing insignia. A

yellow code

number that was outlined in black appeared on the forward fuselage sides. Red

stars outlined in white added to four positions. The pale blue underside of

wings carried solid red stars. The entire interior was light gray while seats

and straps were brown and dirty white respectively. The kit was finally given an

overall coat of semi gloss varnish.

yellow code

number that was outlined in black appeared on the forward fuselage sides. Red

stars outlined in white added to four positions. The pale blue underside of

wings carried solid red stars. The entire interior was light gray while seats

and straps were brown and dirty white respectively. The kit was finally given an

overall coat of semi gloss varnish.

| CONCLUSIONS |

February 2010

If you would like your product reviewed fairly and quickly, please contact me or see other details in the Note to Contributors.