Classic Airframes 1/48 Macchi C.200

|

KIT

#:

|

96-403

|

|

PRICE:

|

$30.00 MSRP in 1996

|

|

DECALS:

|

Two options

|

|

REVIEWER:

|

Andrew

Garcia

|

|

NOTES:

|

Short run kit with etched and resin parts. Vac canopy

|

The Macchi

C.200 Saetta, a term which I have seen translated into “Arrow and “Thunderbolt”,

was a radial engine fighter (also identified as the MC.200) built by Aeronautica

Macchi in

Italy,

and used in various forms throughout the Regia Aeronautica (Italian Air Force).

It had a distinctive cowl using the Magni-NACA separate streamlined fairings

over its rocker arms for maximum speed. It also had a distinctive copper surface

front cowl oil cooler. The MC.200 had excellent maneuverability and general

flying characteristics left little to be desired. Stability in a high-speed dive

was exceptional, but it was under armed with only two .50 cal fuselage mounted

guns and under powered.

The first

prototype (MM.336) C.200 flew on

24 December

1937.

It was followed by the second prototype early the next year. During testing, the

aircraft attained 805 km/h (500 mph) in a dive, although it could achieve only

500 km/h (310 mph) in level flight due to a lack of engine power. Nevertheless,

this was better than the performance of the competing Fiat G.50, Reggiane

Re.2000, A.U.T. 18, IMAM Ro.51, and Caproni-Vizzola F.5.

The first

prototype (MM.336) C.200 flew on

24 December

1937.

It was followed by the second prototype early the next year. During testing, the

aircraft attained 805 km/h (500 mph) in a dive, although it could achieve only

500 km/h (310 mph) in level flight due to a lack of engine power. Nevertheless,

this was better than the performance of the competing Fiat G.50, Reggiane

Re.2000, A.U.T. 18, IMAM Ro.51, and Caproni-Vizzola F.5.

From the time

Italy

entered war on

10 June 1940,

until the armistice of

8 September

1943;

the C. 200 flew more operational sorties than any other Italian aircraft. The

Saetta ranged over

Greece,

North Africa,

Yugoslavia,

across the

Mediterranean

and

Russia.

Its very strong all-metal construction and air-cooled engine made the aircraft

ideal for ground attack and several units flew it as a fighter-bomber. Over

1,000 were built by the time the war ended.

The Saetta

underwent very few modifications during its service life. Aside from the switch

to an open canopy, it started out with an enclosed canopy (!); later aircraft

were fitted with an upgraded radio and an armored seat. Some late-production

Saettas were built with the MC.202 Serie

VII

wing, thus adding two 7.7 mm (.303 in) Breda-SAFAT machine guns to the armament.

The five

general versions of the C.200 were:

M.C. 200

(prototypes) - Two prototypes fitted with the 840 hp Fiat a.74 RC 38 radial

piston engine.

M.C. 200

various “serie” numbers for interim versions - Single-seat interceptor fighter,

fighter-bomber aircraft. This was the general production version. There were “serie”

modifications so use a reference photo because the use of prop spinners or no

spinner, covered and open canopy’s, a mass balance vertical tail versus a

straight tail surface, radios and no-radios, two types of props, and even some

wing guns when the C.202 wing was used on final production variants all come

under this “general production” version nomenclature.

M.C.200bis -

Breda-proposed modification with a Piaggio P.XIX R.C.45 engine producing 1,180

hp. His aircraft was a conversion from an early production C.200. It did not

enter production as the C.200 had been replaced by more advanced designs such as

the C.202/205 using the German DB series of inline engines.

M.C.200AS –

this was an adapted version for North African Campaign featuring an underside

oil cooler in addition to the cowl ring cooler.

M.C.200AS –

this was an adapted version for North African Campaign featuring an underside

oil cooler in addition to the cowl ring cooler.

M.C.200CB –

the fighter-bomber version capable of carrying 710 lbs of bombs or two external

fuel tanks as a fighter escort for supply transports.

The Saetta was

to have been replaced outright by the C.202 after only one year in production,

but the C.200's service life was extended because Alfa Romeo could not produce

enough of the RA.1000 (license-built DB 601) engines, and more C.200s were built

using C.202 parts while waiting for production to increase.

Classic

Airframes (CA) released the Macchi C.200 in 1996. It was their third

release (# 403) of injection moulded kits. C.A. had previously established a

great reputation for finely made resin kits of inadequately or under represented

subjects. I enjoyed getting my hands on every Classic Airframes release and

admiring the multi-media (plastic, resin, white metal and etched parts) solution

to enhancing the details of 1/48th scale aircraft. The resin detail

parts were always amazing. The discontinuation of CA business operations was

truly a sad event.

This is my

first effort building a Classic Airframes (CA) kit even though I have every

release in my stash and have purchased them since 1995. I have a complete stash

of CA kits starting with the first release, Kit #401, of the injected CA kits

and I truly hope to build all of them. The additional effort required to clean

up the kits plastic, the dusty work with delicate resin and attaching some very

tiny etched metal parts has relegated some wonderful CA subjects to a permanent

future build status because they do take much more time to build than mainstream

plastic kits. For some modelers the need for constant dry fitting, sanding,

filing, and test fitting leads to incompletion. I know on this build the resin

cockpit fit gave me some concern. But - the future has arrived and I

am now

building CA kits!

am now

building CA kits!

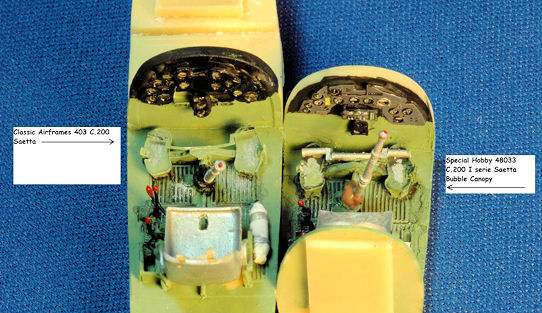

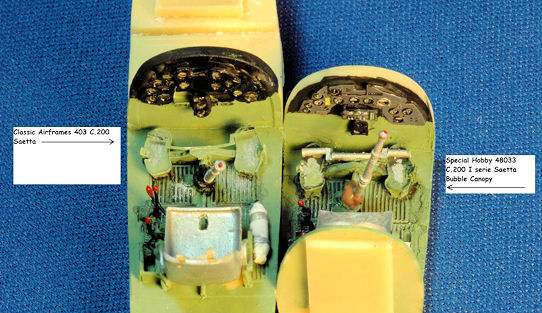

As a result

of a recent purchase of the Special Hobby 48033 Aermacchi C.200 I serie “Bubble

Canopy”, I was curious to see if the parent manufacturer MPM or Special Hobby

(SH) re-released the kit I already had as CA # 403 Macchi C.200. I am so

accustomed to the Hasegawa re-boxing process I expected to find the same plastic

and resins in both kits. The answer was - No, they are not the same kits. There

is a dramatic improvement in the injection plastic and some parts of the resin

in the SH kit. The SH 48033 kit is not a re-release of the old CA parts in any

way. The plastic and resin parts are totally different. The Special Hobby kit

has no etched metal and no white metal parts. The SH plastic is a decidedly

different plastic moulding and the resin while quite nice is not the same.

Back to the CA

# 403 Macchi C.200. Overall fit

is adequate and representative of roughly moulded limited run low-pressure

injection plastic, with a very low parts count. This makes for a simple assembly

process of the plastic parts. It also causes quite a bit of test fitting and

filing, as well as cutting and sanding preparation and final post assembly

sanding is required. There are several thick stubs on the inside of the plastic

from the mould release (punch-out) pins requiring a bit of cleanup. Surface

detail is reasonably refined and panel lines are thinly scribed in a petit to

scale manner giving a good impression in the box. It also looks good after the

kit has been painted and assembled. One vac-form canopy is provided. Mine has

not yellowed but I have seen several CA kit canopy turn amber yellow. It may be

tied to storage conditions since my kit has been in a cool dry location since

its purchase in 1996.

The CA cockpit

resin is very nice. It stands the test of time and it is of equal quality to the

best aftermarket resin sets of today. I was very pleased with its appearance

after painting and dry brushing. There were moments when I struggled to attach

the many etched metal levers and “T-handles” thinking has anyone tried to do

this mating of tiny etched metal parts and resin before me? (Your

editor asked the owner of CA at one time if anyone actually built any of his

kits prior to packaging at release. I was told no as the folks who did the resin

and the folks who did the plastic bits are not even in the same city and the

resin folks never see the kit into which they are to be fitted. This, I was

told, was to prevent piracy. I also read on a forum that MPM's 'beginners' designed CA

kits due to the huge number, for a short run kit, that were produced. It also

was less expensive than using the 'first team'. It goes a long

way to explain why many CA kits are a b**ch to build.)

The CA cockpit

resin is very nice. It stands the test of time and it is of equal quality to the

best aftermarket resin sets of today. I was very pleased with its appearance

after painting and dry brushing. There were moments when I struggled to attach

the many etched metal levers and “T-handles” thinking has anyone tried to do

this mating of tiny etched metal parts and resin before me? (Your

editor asked the owner of CA at one time if anyone actually built any of his

kits prior to packaging at release. I was told no as the folks who did the resin

and the folks who did the plastic bits are not even in the same city and the

resin folks never see the kit into which they are to be fitted. This, I was

told, was to prevent piracy. I also read on a forum that MPM's 'beginners' designed CA

kits due to the huge number, for a short run kit, that were produced. It also

was less expensive than using the 'first team'. It goes a long

way to explain why many CA kits are a b**ch to build.)

I like having

the levers and “T” handles but there has to be some usability engineering

provided in the kit design. Some forethought into etched metal glue attachment

points would be a good change. I would appreciate some thinking going into ease

of attachment of these tiny bits. I do want and like to have these diminutive

details present on all my models. Resin or etched is the way to get there due to

injection plastic moulding limitations.

After all this

effort will I be able to see much inside a very small cockpit? After building

the kit the answer is not really. It is a small cockpit with an almost enclosed

canopy giving an encapsulated shape once the clear parts are attached so this is

not a big concern – just an observation or opinion. After all, if there is any

chance in seeing it I do want to detail it. It is an open cockpit so my

preference is to have every detail present and well finished. The combination of

resin and etched metal gives you that opportunity. I have to say Jules did a

superlative effort in detailing this kit with some excellent resin and brass

details. I am still impressed by his results, and this is one of the early kits.

There are

other ways to create a nice, improved, instrument panel and add some additional

cockpit detail. The alternative is to use the kit resin, some Evergreen plastic

and some punched–out aftermarket decals from Mike Grant for example for the

instrument faces. An interesting aside on the cockpit was my discovery of the

significant size difference when comparing the Classic Airframes cockpit length

with the Special Hobby 48033 kit resin cockpit. The CA resin appears much more

detailed and is about two scale feet longer than its comparable Special Hobby

version.

For the other

teeny bits I prefer to do some drilling and add thin guitar wire rods with white

glue knobs as a somewhat easier way to detail the cockpit levers instead of

attaching minute flat handles and thin resin rods.

The Macchi

C.200 and 202/205 series have a unique seat belt arrangement. It appears the

C.200 only had a shoulder belt with a padded seat back/parachute pack. They all

appear to have a metal chain securing the seat belts or lower parachute backpack

to the cockpit floor. Also, the same chain arrangement appears to secure the

bottom of the seatback pad to the seat or floor as well. My point is there does

not appear to be the usual lap belts in this series of Macchi aircraft. The

chains are not represented in the CA # 403 C.200 etched metal. They do appear in

the Eduard etched sets for the C.202/205 and Italeri MC.200 kits etched sets.

The  Eduard Zoom has both parts, the shoulder belt with chains and the floor to

seat chain restraining device. The CA resin seat has a hole to allow you to

thread the chain up from the floor through the seat bottom. The upper part of

the seat belts from the CA etched fret is adequate but missing the chains.

Eduard Zoom has both parts, the shoulder belt with chains and the floor to

seat chain restraining device. The CA resin seat has a hole to allow you to

thread the chain up from the floor through the seat bottom. The upper part of

the seat belts from the CA etched fret is adequate but missing the chains.

The engine

cowl is a two part injection plastic component. The front end is missing the

many facets from the corrugated copper oil cooling ring. A good photo will

disclose the oil cooling ring (a surface-type oil cooler, of soldered or brazed

construction using brass ribs) is made up of many small copper or brass wedges

or strips welded together with noticeable demarcations between the copper

strips. The CA kit plastic is a smooth surface. The corrugated nose finish would

have been better accomplished if the entire cowl had been cast in resin. No

aftermarket supplier that I am aware of issued any products to fix this area.

The seams created by a two part plastic cowl and having to attach the many resin Magni-NACA engine cowling valve fairings was not a good model design.

See the associated photo comparison of the CA cowl versus the Special

Hobby resin to get a better idea of the merits of each approach. It is a close

fit between the engine and cowl so be mindful when adding the resin cylinders to

the crankcase.

The kit decals

are printed by Propagteam. They are thin, nicely printed crisp graphics but

require some care when applying them since they tend to stick and not move when

applied. My previous experience with Propagteam decals like the ones with this

kit are they will resist relocation and not move once applied; unless you float

them on some saliva (water alone doesn’t work). I did not have any problems with

these decals, nor did I have to use the saliva application process to apply

them. I did use some Micro Sol “just in case” and they were so thin they look

great once they were applied.

In later years Classic Airframes changed

to using Microscale decals which are fantastic and at the end of CA kit

production, in 2008, CA was using crisply printed Cartograph decals. The kit has

a color decal placement and painting guide printed on glossy enameled paper

which is excellent. Jules produced a fine modeling package!

There are

other kits of the MC.200 Saetta now available such as the

Special Hobby # 48033 Aermacchi C.200 I

serie “Bubble Canopy”, Pacific Coast Models 48001 MC.200 Saetta Series

VII

(which I think uses the same Special Hobby plastic but adds etched metal parts),

and the two Italeri MC.200 releases. I have seen some modelers completed builds

of the Special Hobby, PCM and Italeri kits and they all look terrific. Also,

remember there have been resin kits available of the C.200 as well. Scott Van

Aken provided us with a great build of an Astrokit C.200 Saetta many years ago.

There is a

resin cockpit set from Pavla, # 48020, which is intended for the Italeri C.200

kit, which could be adapted to this model. I think the CA kit’s resin cockpit is

comparable and more than suffices for this kit. I have the Italeri kit and while

adequate a comparison of the Italeri cockpit plastic to CA resin parts has the

CA kit winning the detail contest but not the assembly effort comparison. I

found the CA resin cockpit to be somewhat more detailed than the newer Special

Hobby resin cockpit as well. The

CA kit instrument panel was missing the

prominent Macchi cockpit feature of a bell-shaped Magnetic compass although the

hole for it existed in the etched metal parts PE12 and PE22 instrument panel.

CA kit instrument panel was missing the

prominent Macchi cockpit feature of a bell-shaped Magnetic compass although the

hole for it existed in the etched metal parts PE12 and PE22 instrument panel.

The kit

provided decals for two C.200 versions one in Sicily; 86th

Squadriglia, 7th Gruppo, 54th Sormo Caccia Terrestre,

1940-1941 Sicily, Italy and one in Russia; 369th Squadriglia, 22nd

Gruppo Autonomo Caccia Terrestre, 1941 Stalino, Russia

with the yellow cowl and fuselage bands typical of that theatre of

action. Both have the same essential color scheme of overall green “Verde

Mimetico 3”, with the patterned hazelwood brown “Giallo Mimetico 4” splotches

accompanied by smalled Bruno Mimetico splotches inside the Giallo.

I have the Sky Models 48-021 decal with

37 different C.200 options

which Scott used on his Astro Kit build. I learned quite a bit about the C.200

versions by closely examining the Sky Models profiles. It gave me some ideas for

future builds to get a complete set of all the versions of Macchi C.200’s! I

miss Skydecals too!

There are a pair of Tauro

Models decal sheets which could enhance painting of the multi-layer camouflages

for this aircraft, Tauro 48455 Amoebas and Worms Breda Style and 48457 Italian

Camouflage Breda Style 2 could be helpful for some of the complex camouflage

used by the C.200. Although not C.200 specific it looks like they could work on

some Italian aircraft schemes where finer air brush work would not be enjoyable

or attainable for most modelers.

As I

mentioned previously, this is my first build of a Classic Airframes kit. Since I

have done many conversions and added quite a few resin cockpits and etched bits

to my kits over the years there was nothing new or difficult with this kit.

There is just a lot of effort required to cut, shape and test fit, and then dry

fit all parts. Metal pins are recommended to improve the many butt fitted

contact points. Some of the plastic parts could be better detailed such as the

propeller hub so I added that to my construction plans. That could also be

looked at by a modeler as an opportunity to add some value through the

application of modeling skills and creative solutions rather than a boring

exercise in assembly.

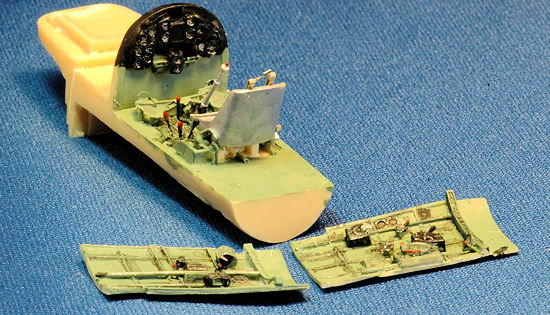

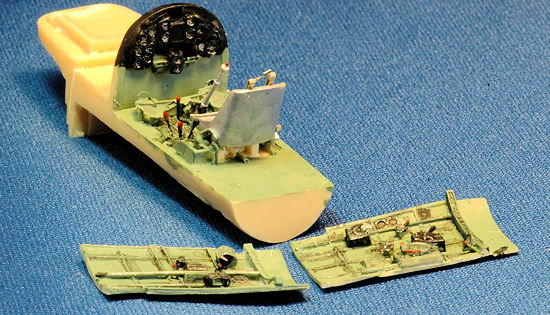

I started

the kit per the instructions which are easy to follow and well done. It consists

of six steps starting with the resin cockpit, step “A” and all its etched bits.

Inserting the completed resin cockpit tub and mating it to the sidewalls was a

modeling challenge. There are no locator pins or guiding marks so you are left

to you own resolution of what goes exactly where when it comes to adding the

completed cockpit tub. There is an odd fit where the seat back goes under the

rear cockpit wall where the armored headrest is located. I don’t think this is

what I have seen from the MC.200 cockpit photos. I built the Special Hobby and

Italeri kits in parallel to assist in kit comparisons and when compared side to

side the CA cockpit tube was quite a bit longer.

I started

the kit per the instructions which are easy to follow and well done. It consists

of six steps starting with the resin cockpit, step “A” and all its etched bits.

Inserting the completed resin cockpit tub and mating it to the sidewalls was a

modeling challenge. There are no locator pins or guiding marks so you are left

to you own resolution of what goes exactly where when it comes to adding the

completed cockpit tub. There is an odd fit where the seat back goes under the

rear cockpit wall where the armored headrest is located. I don’t think this is

what I have seen from the MC.200 cockpit photos. I built the Special Hobby and

Italeri kits in parallel to assist in kit comparisons and when compared side to

side the CA cockpit tube was quite a bit longer.

While doing this step I kept thinking

ahead to the step “F” process where the engine is mated to the fuselage. There

is not much room between the rear of the engine resin and the front of the

cockpit tub which forms the upper part of the landing gear bay. The cockpit tub

has a two part structure which includes the front wheel well detail. I used a

metal rod to support the attachment of engine core to the fuselage tub. While

this helped establish a secure join between the resin engine and the fuselage

you could mis-align the cowl unless care is taken with the metal pin attachment.

Once completed all the parts of the cowl did not line up. This area is where the

Italeri kit is a big improvement over the CA and SH kits.

The gunsight appears to be joined to the

instrument panel in Step “A” but its location and the actual rim of the cockpit

do not permit this to work. I added the gunsight after all assembly was

completed to the edge of the cockpit rim beneath the front windscreen.

The

gunsight is a nice resin casting but the clear portion, part # E, found on the

instrument panel acetate film, was incorrectly produced. It is a completely

blacked out segment instead of a black outlined part with a clear center

section. It looks like a misunderstanding between the designer of the parts and

the printer or manufacturer of the parts occurred. I worked around this by

cutting a piece from another part of the clear acetate film using the incorrect

part as a size guide.

The second

step, fuselage assembly, produced some problems. The fit of the upper wing to

the fuselage was off by about 1/16th of an inch. It is more than a

snug fit and I had to cut the upper wing mating surfaces where they touch the

fuselage after I glued the wings together. Sometimes this is caused by the

assembly approach or my incorrect assembly. That is, you could avoid this

mismatch by attaching the lower wing to the fuselage then fitting the two wing

top parts. A misfit is fixed by sanding the wing tips rather than cutting away

at the wing to fuselage mating surfaces. In the actual aircraft one wing is

intentionally longer. This was done to compensate for engine torque in the

C.200.

The

interior is the first part to be constructed. It consists of a seat, sidewalls,

instrument panel and control column. After painting a wash of dilute flat black

followed by some silver dry brushing left me pleased with the resin cockpit. The

etched metal seat belt once painted and glued onto the seat enhanced the

cockpit.

Step “G”

(which you will find in a sub-box with step “B”) is the addition of the tail

wheel and its supporting plastic roof. A very nicely detailed resin rear wheel

is provided. I attached part 13 to one fuselage side first securing the plastic

part # 13 with plastic glue. When it was hardened, the next day, I used some

clear epoxy to provide a stronger join and reinforcement for this part since I

thought it might separate once the kit fuselage halves were closed and weight

applied to the rear wheel.

Step “G”

(which you will find in a sub-box with step “B”) is the addition of the tail

wheel and its supporting plastic roof. A very nicely detailed resin rear wheel

is provided. I attached part 13 to one fuselage side first securing the plastic

part # 13 with plastic glue. When it was hardened, the next day, I used some

clear epoxy to provide a stronger join and reinforcement for this part since I

thought it might separate once the kit fuselage halves were closed and weight

applied to the rear wheel.

I added a

small metal rod to this part by drilling a hole in the upper resin and gluing it

to the stirrup shaped lower resin fork. By using a very fine piece of guitar

wire the strength and rigidity it provides minimizes the potential of breakage

of a delicate and brittle resin part that will be subjected to unfortunate

handling or display impact. Because it is very thin it does not detract in a big

way but that is your choice since it does take away from the thin delicate resin

casting. An alternative is to drill through the resin from the top down into the

wheel and run the rod inside, essentially out of sight. That is the best

approach but requiring precision and patience that exceeded my goals for this

build. I wanted to see how the kit looked after the build before investing too

much time in a contest winner with fundamental flaws in shape or outline.

Obviously you could just leave it alone and hope the resin does not snap.

I thought

of varying from the kit instructions regarding installing the cockpit interiors.

It is possible to leave off the cockpit resin tub and install it after the

fuselage is joined together. I test fit this approach taping the fuselage

together and inserting the tub afterwards. You can do this if the wings are not

yet attached. This can be done as it is basically an open cockpit aircraft.

Once the

interior parts had been painted, the instrument panel was glued onto the resin

tub front bulkhead. I found the Evergreen styrene sheet, #9010 .010 inch, since

it is so thin yet mildly inflexible to be a good backing material for the etched

metal and clear acetate instruments Eduard instrument panel “sandwich” as well.

The newer

Eduard etched parts don’t need this white backing since the etched has the white

portions printed directly onto the etched parts.

I have not

had good results using etched metal with the clear acetate instrument backing

since they often look washed out or are barely visible or worse the glue and

white paint backing separate and the instrument panel comes loose during the

late stages of construction or after painting. I have started to use a white

styrene plastic sheet backing on the etched parts with a small application of

Gorilla Glue to get better results. The amount of glue applied has to be very

slight and very thin or you will not be happy with the results because it will

ooze and bubble when it cures. The best solution would be a new Eduard color

ZOOM

for all MC.200 1/48 kits since there are now Special Hobby, Italeri/Tamiya

releases as well that could benefit from the Eduard color zoom treatment. The

biggest contribution the Eduard etched makes is for the replacement instrument

panel and seat restraining chain with seat belts in pre-painted color which

Eduard does so well.

The

completed resin cockpit kept shifting when I tried to add it to the fuselage. I

was never 100% sure it was in the right place. There is a small diagram in the

instructions, step “S” that combined with the diagram for step “B” completes the

mating of the seat with its harness and resin cockpit tub.

The

completed resin cockpit kept shifting when I tried to add it to the fuselage. I

was never 100% sure it was in the right place. There is a small diagram in the

instructions, step “S” that combined with the diagram for step “B” completes the

mating of the seat with its harness and resin cockpit tub.

The cockpit

to fuselage mating was not a happy event. The kit engineering is lacking in this

area. I would have enjoyed having some type of pin or protrusion on the inside

of the fuselage to indicate proper cockpit tub placement prior to sealing things

up. Through test fitting, more cutting and trial and error it worked. The

difficulty is enhanced though the addition of resin part PU6 which is the wheel

bay interior detail since PU6 attaches to the front of the cockpit resin tub.

Why weren’t these two parts cast as one unit? Although I enjoyed the modeling

challenge of this limited run kit and love the subject matter, the cockpit

assembly and integration into the fuselage plastic was difficult and annoying.

I actually

had a moment where I thought it would be a better idea to take a Hasegawa C.202

kit and attach the CA kit radial front end as an easier way to get a happy

modeling experience because I had set it aside a few times as a no fun exercise

frustrated by the cockpit positioning and alignment problem. But, I really

wanted to complete the build so I made it work basically by grinding away at

some of the resin cockpit components and jammed it in. This only worked because

it is a small cockpit and you don’t see much once it is inserted. For this part

of the build Slo-Zap thick and slow curing Cyano Acrylate (CA) glue was my

friend! Once all the sanding, grinding and repeated dry fitting was over I used

the thick slow curing cyano glue to hold the cockpit walls in place. I had to

use a Dremel micro router bit to cut back some interior resin to permit the trim

wheel area to fit. The Slo-Zap was instrumental in solving the “how do I get

parts that don’t click together and have no locator pins to stay in place”.

I used the

Panaflex vise as a part holder (see photo) for much of the cockpit assembly. By

placing the resin cockpit at the correct angle the part would stay in place long

enough to allow the slow cure to work and fill some of the small gaps created by

the cutting and trimming dry fitting process. I had to deviate from the

instructions by gluing plastic part # 14, which is the top front of the

fuselage, to the left fuselage in order to ensure the resin cockpit tub and

resin cockpit walls would fit. The rear of part # 14 is part of the fitting

requirements and in step “B” of the instructions.

The final

procedure I settled on was gluing the right sidewall onto the cockpit tub. Once

this was dry I test fitted the tub with one sidewall by closing the two fuselage

halves. I then attached part # 14 to one of the fuselage halves. Once dry I

glued the other cockpit wall in place test fitting it to ensure it would close

together. I used Slow-Zap CA to secure the cockpit and some masking tape to hold

the fuselage parts together. A few Berna clamps were also used and I waited

until things set overnight. The next day I glued the remaining cockpit wall in

place using a few metal clips along the top to attach them to the plastic

fuselage. The cockpit wall was essentially held in place by the glued in tub

before this step.

I gave up

on trying to insert a completed cockpit tub up through the opening where the

wings would go due to the shifting tub problem. There is a potential concern

with part 14, which is the top front section of the fuselage resulting in large

gaps on both sides. A kit designer has many choices to make and some have both

positive and negative impact. In this case part # 14 leaves large rough seams on

two sides of the front fuselage nose section. The alternative would have been to

mould the fuselage into two halves without this extra section. The SH kit for

example followed the alternative and was much easier to assemble, eliminating

the putty and sanding exercise that occurred with the CA kit.

The wings

were cut to fit within the fuselage width space. What this means is they did not

fit and it required some cutting and modeling effort to have the wings mate (see

photo). Since they are plastic I used plastic glue to close the seam up. I

noticed the actual aircraft has a prominent wing tip light with the inner orb

(the side facing the pilot) painted so that it creates a half-shell light which

helps others in formation without affecting the pilots night vision. The wing

lights are represented as two very small bulges in the kit wings. Due to the low

pressure roughly moulded plastic one wing tip light was partially sanded off by

accident when I was preparing the wings by sanding off the many rough plastic

bumps. I took two straight pins (the type without the pearl heads)

and inserted

them in the area on the wing tips that had a small bulge. The Special Hobby

48033 kit has a better crafted wingtip light by the way.

and inserted

them in the area on the wing tips that had a small bulge. The Special Hobby

48033 kit has a better crafted wingtip light by the way.

Once the

wings were on, it was time for the tail section. The vertical fin/rudder was

part of the fuselage plastic part # 1. I used a few light applications of Aves

Apoxie Sculpt filler to blend it in since there was a gap on the starboard side

fin to fuselage join that using plastic cement did not fill. After this step the

horizontal stabilizers were glued in place. I used pieces of metal straight pins

to attach the horizontal stabilizers and make a firm bond since they are butt

joins.

The next

step, “C”, which is the undercarriage was a bit problematic. The locating holes

and end part of the landing gear mating was not very secure. Essentially, the

mounting of the white metal parts to the wing landing gear cavity was a

challenge requiring care and patience. I used epoxy on this part as well and

used the Panaflex vise with rubber jaw guard to hold the kit upside down to

permit this slow bond to work. I then added some Aves Apoxie Sculpt around the

top of the landing gear leg, inside the gear cavity to secure it even further –

it just seemed too fiddly without this extra effort.

The inside of the main gear well of an

actual C.200 is highly detailed with exposed parts, pneumatic hoses, cables and

wires. CA provided a number of etched parts for detail in this area but they are

mainly for the landing gear. This misses the need for the hoses and wiring that

are the bulk of the details.

Since it is

quite open and exposed with a lot of plumbing you can super detail this area if

you wish. I used the kits resin and etched metal and placed a few pieces of

copper wire and bass guitar wires for the hydraulic hoses and electrical wiring

and called it a day. This is an ideal place for a multi-part resin enhancement

since color photos on page 60 and 70 of the Macchi C.200 SAETTA, Orange Series #

8113, Stratus Books, Mushroom Model Publications reference show the complexities

of this area. The CA kit is partially missing the tubular support structure

which is another prominent feature and part of the SH kit. The CA kit has the

lower tubular section represented in a 2D manner in the landing gear bay resin

roof. This section is also simplified in the Italeri kit. Special Hobby has the

tubular parts in its design but also is lacking in the other details.

While all

this was going on, during the paint drying wait time, I worked on the engine

cylinders and cowling as they are the next steps, items “D” and “E”. The CA

cowling is a very interesting piece of work. It consists of two halves with no

blisters. You have to remove the NACA blisters from their resin carriers and

then attach them to the plastic cowl. I thought it would have been much better

to have a one piece resin cowling with the NACA blisters already there as is

found on the Special Hobby release. Aligning the plastic cowl halves, parts 5

and 6 is also a challenge because there are no locator pins. The kit

instructions show the cowls with the blisters on in the first page kit contents

diagram. In step “E” you are challenged to attach the blisters and join the cowl

halves. I taped the cowl halves

together and started by only gluing the ends. Once this set, the next day, I

removed the tape and re-glued it inside and outside. Later the next day I

started to fix the seams. Once this was completed it was time to remove the NACA

blisters from the resin pouring blocks and attach the resin blisters to the

plastic cowl. There are two blisters which are not as tapered (parts PU 2) that

go on the top. Once painted it does

look very nice much to my surprise.

I cut and

glued on each cylinder to the main engine block using metal straight pins as

connectors with some cyano glue for the join. This may not be necessary but I

have never had a cylinder come off with the rough handling caused by inserting a

very tight fitting engine into the cowl such as with this assembly. I detailed

the engine by adding spark plug wires and also using plastic rod for the

cylinder push rods instead of the etched metal part # 16. I thought at first

this etched metal part was the ignition wiring harness because it was similar to

those found on many Eduard etched metal sets as a wiring harness.

After

looking at some photos of the actual aircraft in an Italian museum it seemed it

was intended to replicate the prominent pushrod sleeves. I left it, the kit

supplied etched part off because it looked too flat and was not a drop fit after

I test fitted the etched part. The plastic rod looked much better. I would have

appreciated it if the resin cylinders had this, the pushrod sleeves, moulded on.

The Special

Hobby kit, # 48033 is also missing the prominent external valve pushrods. The

Italeri kit does a good job with this section providing the pushrods attached to

the front and rear of the engine crankcase along with the engine exhaust piping.

Also, looking at the museum aircraft it seems the wiring harness is behind the

engine and not in a ring at the front as is usually found in American radial

engines so it would not be accurate to add a wiring harness to the front end so

I believe the etched was intended to represent the pushrod sleeves.

The Special

Hobby kit, # 48033 is also missing the prominent external valve pushrods. The

Italeri kit does a good job with this section providing the pushrods attached to

the front and rear of the engine crankcase along with the engine exhaust piping.

Also, looking at the museum aircraft it seems the wiring harness is behind the

engine and not in a ring at the front as is usually found in American radial

engines so it would not be accurate to add a wiring harness to the front end so

I believe the etched was intended to represent the pushrod sleeves.

The gun

troughs are only a starting point and need to be opened.

The resin machine gun tubes were too plain for me to use. They are

lacking the air cooled perforations. It would have been perfect to have the

resin tubes plus a perforated etched metal cooling jacket. I substituted the

Quickboost QB48342 MC.200 Saetta Gun barrels resin replacement set. Although it

is for the Italeri kit it is adaptable to this model. It appears in later

MC.200’s the extended blast tubes were removed, similar to the MC.200, serial #

M.M. 7707 which is a late serie

VII

airframe, found in the Museo Storico dell’ Aeronautica Militare Italiana. An

alternative was to use the Master model AM-48-054 Breda Safat 12.7mm brass gun

tubes for the resin tubes provided with the kit. The Master brass guns are

stunning. There is no comparison to a resin moulded gun tube – they are that

much better. The brass looks much better and compared to just using regular

brass tubing there is no comparison with the drilled cooling jacket and gun tube

insert Master model provides. However, since this kit has a few shortcomings

induced by my modeling skills, I opted to use the Quickboost part and save the

Master gun tubes for another build. The CA supplied gun barrels are simple tubes

and just need to be drilled out. I saved them for another day.

The front

cowl addition was glued in place but it was a very careful process since the

first time I tried to fit it onto the engine a few pushrods were knocked loose.

It is a tight fit but it does work. I also secured the engine and cowl to

the fuselage by inserting a metal rod into the rear of the resin engine and

mated it to the tip of the cockpit tub.

I used the kit

supplied decal for an aircraft from the 86th Squadriglia, 7th

Gruppo, 54th Stormo Caccia Terrestre 1940-1941 based in Sicily,

Italy. I initially chose the second color option for the 369th

Squadriglia, 22nd Gruppo Autonomo Caccia Terrestre, 1941 Stalino,

Russia because the yellow cowl bands are so colorful. Since I will be building

the Italeri C.200 and that kit has a similar (not identical) marking for a 369th

Squadriglia, 22nd Gruppo aircraft I went with choice “A” in the CA

kit.

The C.200 had

three general types of camouflage color schemes, mottled, desert and single

color. Within these classes are four mottled subtypes, three desert subtypes and

two solid color schemes. I recommend you get the

Mushroom Publications No. 8113 book for

a complete description of these. They are very interesting camouflages and a

wonderful challenge to paint. The alternatives make for very attractive

finishing options. Mushroom Publications book made this part a reality – no more

wrong guesses! The superb Aero Detail # 15 book also has camouflage color

information on page 65 but it was simplified compared to the expanded coverage

in the MMP book. The Mushroom Publications No. 8113 book has a very detailed

expansion on the camouflage schemes, especially the mottled ones on page 10,

which I found most helpful.

Once the white fuselage

band was painted and masked off, the underside of the wings and tail planes were

painted Grigio Mimetico (light grey). I used Tamiya acrylic colors for this as

they are called out including mixes in the instructions for a Tamiya released

version of the Italeri C.200 kit. I looked up the instructions online and felt

more confident using the Tamiya acrylics for this project.

I initially

chose to model the plane from the 369th Squadriglia, 22nd

Gruppo Autonomo Caccia Terrestre, 1941 Stalino, Russia with the yellow cowl,

under wingtips and fuselage bands because it is very colorful. A profile of it

can be found on page 86 of the Macchi

C.200 Saetta Orange Series # 8113 Mushroom Publications book and a similar

aircraft is in an Italian aviation museum with some fine photos available on the

web for this color scheme. However, since I plan on building several versions of

the MC.200, I went with the first color scheme in the CA color guide for

the 86th Squadriglia, 7th Gruppo, 54th Stormo

Caccia Terrestre aircraft. Regrettably

the color profiles are small and that made it difficult to match but having them

is a great help and much better than what most other kits offer. Again I

complement Jules B. on putting all the pieces needed together in one package.

Remember, most Regia Aeronautica aircraft like the MC.200 had the upper wing

color wrap around the leading edge about 6 to 8 inches underneath the wing.

I initially

chose to model the plane from the 369th Squadriglia, 22nd

Gruppo Autonomo Caccia Terrestre, 1941 Stalino, Russia with the yellow cowl,

under wingtips and fuselage bands because it is very colorful. A profile of it

can be found on page 86 of the Macchi

C.200 Saetta Orange Series # 8113 Mushroom Publications book and a similar

aircraft is in an Italian aviation museum with some fine photos available on the

web for this color scheme. However, since I plan on building several versions of

the MC.200, I went with the first color scheme in the CA color guide for

the 86th Squadriglia, 7th Gruppo, 54th Stormo

Caccia Terrestre aircraft. Regrettably

the color profiles are small and that made it difficult to match but having them

is a great help and much better than what most other kits offer. Again I

complement Jules B. on putting all the pieces needed together in one package.

Remember, most Regia Aeronautica aircraft like the MC.200 had the upper wing

color wrap around the leading edge about 6 to 8 inches underneath the wing.

The cockpit

and wheel wells of the C.200 were painted in a color which comes from my

declining stocks of AeroMaster paints (# 1120 U.K. Interior Green Acrylic). The

instructions indicate to use light grey. I chose to use the same color as the

aircraft from the two museums I reviewed prior to building. However, some of

those photos also show a light grey was used in portions of the lower cockpit

areas such as the floor, rudder pedals and lower cockpit walls. The Tamiya

instructions indicate XF-21 Sky and XF-5 Green in a 50% each mixture for the

cockpit. This mixture provides a color similar to the U.K. WWII color of

interior green or cockpit light green.

For the

overall fuselage finish I used Tamiya acrylics. The exact colors used were XF-59

Desert Yellow, XF-52 Flat Earth, and XF-67 NATO Green. The undersides are a mix

XF-2 Flat White (66%) and XF-66 Light Grey (34%) for a very light grey

underside. It was easy to use and the results good with a fast drying time and

no masking pull-up losses. I added some black to the light gray to dirty up the

undersides with some patches or streaked areas. I used Aves Apoxie sculpt to

fill in any gaps such as the wing to fuselage join, and the top of the fuselage

front end. I try to use water and my wet finger tip for most of the gap repairs

when I use Apoxie to avoid sanding away surface details. It is also faster and

easier with an excellent ability to blend in without leaving a seam. Try it you

will like it!

Weathering

and Final Coat – some pastel chalk and black/brown pin wash was used. I sprayed

on a Testors gloss coat to prep for decals and Dull Cote to seal in all the

decals instead using the Future coat used during the initial application to seal

all of the decals.

The props

have a decal stencil which looks more like the Hamilton-Standard emblem than the

Macchi emblem decal on the props. Although the prop is a Piaggio P.1001

propeller it has the Macchi logo on the prop. Take a look at the prop stencils

from the Hasegawa Macchi Mc 202 kit and from the Skymodels decal sheets and

Italeri kits as an example of this logo. The Skymodels sheet for the MC.205

properly shows the two different propeller types (labeled Macchi & Breda)

similar to that used by the C.200 one of which was actually a license built Fiat

Hamilton-Standard 34DI-1 prop hence the similar shaped decal used in the kit and

the other a Piaggio P.1001 prop which was the most commonly used prop on the

C.200. An excellent description and drawing of the prop logos is found in the

Aero Detail # 15 book on page 71. A comparison, drawing and description of the

propeller is found in the Aero Detail # 15 book on page 78. Since the license

built Fiat Hamilton-Standard 34DI-1 prop was only used on the first 25 serie I

units the correct logo is usually the Macchi emblem. The prop hubs also have a

different shape and there are balancing weights on the Fiat Hamilton-Standard

34DI-1 prop hub. The stencils came from the kit decals as well but there were

only a few to apply.

The last

part, Step “F” (Final assembly) consisted of adding the cowl, prop and prop

boss, canopy, twin machine guns, twin wing pitot tubes (PE47) and venturi tube

(PU16). The prop and prop boss plastic were a bit rough and required some clean

up especially to get the very prominent three bolts that secure the prop to the

rear hub to look good. The center of the prop hub is a prominent feature. It was

missing from the plastic prop. I used a clothing straight pin with a small pearl

top as the missing hub tip and as a connector to the resin radial engine. First

I drilled a hole into the resin engine, then using the same diameter drill bit

drilled though the plastic parts 15 and 18. This permitted a good alignment and

a secure bond. By using a pin that had a pearl head I added some

ZAP

CA glue to the tip to fill in the bottom of the pin head. I held it upside down

in an alligator clip device while it dried in an effort to reconstruct the

noticeable end point of the C.200 prop assembly which is missing from the kit

plastic.

I used a

Dremel to hollow up the exhaust stacks, parts # 16 & 17 added in step “E”. I

used a brush and two step process for painting the exhaust pipes. I brushed on

Metalizer Dark Iron non-buffing. When it was dry I used some thinned Pactra IP96

Rust enamel as a wash. Many photo references show the C.200 Saetta exhaust were

painted the same color as the fuselage camouflage colors so you have a choice to

make.

The CA kit

part, PU13, which is a small antenna mast was added at this point. Some clear

sewing thread was used for the antenna wire which was then painted flat black

and attached using gorilla glue. There were three types of communications used

by C.200 pilots resulting in three choices for the modeler. Some aircraft had no

radio using the time honored hand signal methods from WW I and the Spanish Civil

War. Some C.200’s had radios. The radio’s used a small antenna behind the pilot

headrest and some of the antennae’s were connected via a wire to the leading

edge of the vertical stabilizer. I have also seen pictures and a even a color

profile found on page 13 of Macchi C.200 Saetta Orange Series # 8113 Mushroom

Publications using a three point antenna wire configuration attached to the

wings in an arrangement similar to a P-40. This configuration appears on some of

the initial aircraft that were outfitted with radios.

The C.200

has an unusual double pitot arrangement featuring a pitot rod on each wingtip.

The reason for this is one pitot is heated and the other is not. It also has an

unusual cranked upward step with a second small tube under the main tubular

component. CA faithfully reproduced this but it is in flat etched metal. I took

some guitar wire and attached the flat etched metal to it to improve

survivability of this part and also add a “3D” depth to the flat part. I glued

the etch to the guitar wire, added some CA glue to round it out and painted it.

Some C.200’s also appear to have two piece straight tubular pitot’s as well

which I rarely saw in wartime photos. This type of pitot, the simple straight

version is available with the QB48341 Quickboost MC.200 Saetta Pitot Tubes &

Antennas resin. I am not sure how many of these, the straight pitot rods, were

used compared to the cranked one but you will find them both appearing in the

Italeri kits with the cranked pitot on the early fuselage versions and the

straight one in the later version.

The C.200

has an unusual double pitot arrangement featuring a pitot rod on each wingtip.

The reason for this is one pitot is heated and the other is not. It also has an

unusual cranked upward step with a second small tube under the main tubular

component. CA faithfully reproduced this but it is in flat etched metal. I took

some guitar wire and attached the flat etched metal to it to improve

survivability of this part and also add a “3D” depth to the flat part. I glued

the etch to the guitar wire, added some CA glue to round it out and painted it.

Some C.200’s also appear to have two piece straight tubular pitot’s as well

which I rarely saw in wartime photos. This type of pitot, the simple straight

version is available with the QB48341 Quickboost MC.200 Saetta Pitot Tubes &

Antennas resin. I am not sure how many of these, the straight pitot rods, were

used compared to the cranked one but you will find them both appearing in the

Italeri kits with the cranked pitot on the early fuselage versions and the

straight one in the later version.

The landing

gear covers should have a slight bend in order to conform to the tire hump and

wing airfoil shape whereas the etched parts are flat. I used the Special Hobby

Kit # 48033, plastic parts 5 & 6 as the template to shape and form the curve

needed for the flat CA kit etched parts. The curves caused some problems with

attaching these parts so I had to rework things. Adding the etched covers was a

challenge due to the added etched metal attachment points but once done they

look very good and are very accurate with an in-scale look. You do have to be

very careful with these since the etched attachments that hold the covers onto

the landing gear are difficult to glue. I could have done better with mine

placing them a bit lower since it was a learning experience on how to best

attach these. There are no tail wheel doors on this late version of the C.200.

The resin tail wheel is very well casted and well represented.

The clear

vac-form parts were added using Testors 8876C white glue. I use this because of

its long, tapered black plastic applicator that allows small amounts to be

carefully placed. The radio mast and antennae wire was attached using some cyano

to hold it followed by a micro dab of gorilla glue and painted as the last step.

My windscreen clear part was clear and not yellowed. I have seen many CA kits

experience a yellowing of the clear parts. Perhaps storage temperatures have an

effect on long term canopy glass vac-formed parts. I have read where the

material for vac-forms will yellow with time. Mine were still transparent with

no discoloration. I have read the solution is to use PETG plastic for vac-formed

canopies available from K&S plastic. A

spare canopy from the SH kit might help if your kit has this problem. Falcon and

Squadron vac replacements do not appear to be available at this time. There is a

fantastic piece of etched metal, part # PE 29 which is the canopy hood release

latch in step “Z”. What an amazing attention to detail Jules brought to this

model!

The copper

radial oil cooler was painted using Tamiya dark copper XF-28. If you like a

shinier surface you can try titanium gold or even gold with some dry weathering

dry brushing. I liked the Tamiya dark copper shade since it approaches the tone

of a slightly weathered copper visible on the many WWII era color photos of the

C.200.

The C.200

has a small tail light. I painted this silver with a small white dot in the

center. Once the paint was dry I added a drop of clear epoxy to the tip to

simulate the light cover.

The CA

cowling was not up to the high quality of the rest of the kit. The copper cowl

ring is poorly represented lacking in the fine lines representing the brazed

copper panels of the oil cooler ring. There is a notch in the top rear portion

of the plastic cowl parts. I could not determine if it was for ease of

attachment, or an actual nuance of the aircraft cowl or just missing another

component to permit a flap in this section. From reviews of actual aircraft

photos I feel it is a missing part (or I was too eager to cut away at the

plastic when removing it from the trees and notched it by accident). A piece of

kit supplied etched would have been appropriate. There was none and no plastic

part so I used some Evergreen white styrene # 9010 .010 ( i.e. .25mm) inch

thickness sheet to create the missing top of the cowl flap. The part goes on the

cowl between the gun troughs. There may be an etched metal part for this not

called out in the instructions but I found none. The gun troughs are only a

starting point and need to be opened prior to painting. Once the kit was painted

the cowl looked very good so it is not my intent to say the cowl ruined the kit.

It just made it harder to build and introduces some alignment problems with the

armament and lacks the center tab.

There is a

very noticeable seam in the middle of the cockpit armor plate section. I cut a

piece of evergreen sheet plastic and added it to the headrest area. It

covered up the seam and added the missing pilot armor plate. The armored

headrest area is very nicely represented in the Italeri kit # 2676, in part

number 18A.

I really

enjoyed building the Classic Airframes C.200 Saetta. Any comments made were just

modeler musings and sharing building tips in addition to identifying areas of

improvement for scratch builders. While it is not a shake and bake two day build

like the Italeri kit, the challenges were overcome with the application of

modeling skills. I have a few more CA Saetta’s in my stash and look forward to

building them as well to make some other versions of the Saetta appearing on the

Skymodels C.200 decal sheet. The colorful camouflages and paint variations of

the Macchi C.200 Saetta make for a superb painting canvass. The references I

mentioned will be of great help.

The cockpit

is hardly visible since it is a small opening so don’t fret too much about the

inside appearance – just get the seatbelts and seat looking good and you should

be happy. I do hope to see others build this kit and the Special Hobby 48033

Aermacchi C.200 I serie “Bubble Canopy”,

Pacific Coast

Models 48001 Mc.200 Saetta Series

VII,

and the Italeri/Tamiya C.200 releases. I have seen some modelers completed

builds of the Saetta’s from Special Hobby, PCM and Italeri kits and they all

look terrific. It is a small sized aircraft so it won’t take up too much shelf

space. It does stand out in a crowded shelf since the random visitors

(non-modelers) that look at my built kits often ask “what is that” and “what a

cool paint scheme” so it is an interesting aircraft for the casual observer.

The cockpit

is hardly visible since it is a small opening so don’t fret too much about the

inside appearance – just get the seatbelts and seat looking good and you should

be happy. I do hope to see others build this kit and the Special Hobby 48033

Aermacchi C.200 I serie “Bubble Canopy”,

Pacific Coast

Models 48001 Mc.200 Saetta Series

VII,

and the Italeri/Tamiya C.200 releases. I have seen some modelers completed

builds of the Saetta’s from Special Hobby, PCM and Italeri kits and they all

look terrific. It is a small sized aircraft so it won’t take up too much shelf

space. It does stand out in a crowded shelf since the random visitors

(non-modelers) that look at my built kits often ask “what is that” and “what a

cool paint scheme” so it is an interesting aircraft for the casual observer.

The kit did

take a bit of extra effort to complete since it is multi-media. It is an

impressive package for the price producing a very nice looking model. I have

read reviews where some feel the outline is not quite right but after building

it and looking at a lot of references it passes the mark 8 eyeball display test.

While building it I wondered why Hasegawa hasn’t produced the C.200 using parts

from their C.202/C.205 family which are beautiful kits. After building this kit

it would seem a resin conversion set producing the radial front end mating it to

the rest of the Hasegawa plastic could have provided an easier to build kit.

However, the availability of the Italeri kit reduces the probability of this

occurring.

All my

concerns should be taken with a constructive spirit of how to make the most out

of this kit rather than focusing on any serious shortcomings. I am pleased I

built it, enjoying the journey to build the kit and look forward to building

some more of the CA Saetta’s. When I look at the portfolio of kits Classic

Airframes released and the amount of modeling satisfaction from building unique

or non-mainstream subject matter aircraft they provide I sincerely thank and

appreciate what C.A. did for all of us! Sometimes it takes a limited run,

multi-media kit to get all the details right.

Macchi

C.200 Saetta, Orange Series # 8113, Stratus Books, Mushroom Model Publications

2012

Aero Detail

# 15, Macchi C.200/C.202/C.205 Dai Nippon Kaiga, August 1995

C.200 Saetta Scale

Aviation Modeler International Vol. 2 # 8 August 1996

AeroMaster decal # 48-154

Macchi C.200 Saetta

SKYModels decal # 48-021

Macchi C.200 Saetta

Andrew Garcia

January 2013

If you would like your product reviewed fairly and

fairly quickly, please

contact

the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

The first

prototype (MM.336) C.200 flew on

The first

prototype (MM.336) C.200 flew on  M.C.200AS –

this was an adapted version for North African Campaign featuring an underside

oil cooler in addition to the cowl ring cooler.

M.C.200AS –

this was an adapted version for North African Campaign featuring an underside

oil cooler in addition to the cowl ring cooler. am now

building CA kits!

am now

building CA kits! The CA cockpit

resin is very nice. It stands the test of time and it is of equal quality to the

best aftermarket resin sets of today. I was very pleased with its appearance

after painting and dry brushing. There were moments when I struggled to attach

the many etched metal levers and “T-handles” thinking has anyone tried to do

this mating of tiny etched metal parts and resin before me?

The CA cockpit

resin is very nice. It stands the test of time and it is of equal quality to the

best aftermarket resin sets of today. I was very pleased with its appearance

after painting and dry brushing. There were moments when I struggled to attach

the many etched metal levers and “T-handles” thinking has anyone tried to do

this mating of tiny etched metal parts and resin before me? Eduard Zoom has both parts, the shoulder belt with chains and the floor to

seat chain restraining device. The CA resin seat has a hole to allow you to

thread the chain up from the floor through the seat bottom. The upper part of

the seat belts from the CA etched fret is adequate but missing the chains.

Eduard Zoom has both parts, the shoulder belt with chains and the floor to

seat chain restraining device. The CA resin seat has a hole to allow you to

thread the chain up from the floor through the seat bottom. The upper part of

the seat belts from the CA etched fret is adequate but missing the chains. CA kit instrument panel was missing the

prominent Macchi cockpit feature of a bell-shaped Magnetic compass although the

hole for it existed in the etched metal parts PE12 and PE22 instrument panel.

CA kit instrument panel was missing the

prominent Macchi cockpit feature of a bell-shaped Magnetic compass although the

hole for it existed in the etched metal parts PE12 and PE22 instrument panel.  I started

the kit per the instructions which are easy to follow and well done. It consists

of six steps starting with the resin cockpit, step “A” and all its etched bits.

Inserting the completed resin cockpit tub and mating it to the sidewalls was a

modeling challenge. There are no locator pins or guiding marks so you are left

to you own resolution of what goes exactly where when it comes to adding the

completed cockpit tub. There is an odd fit where the seat back goes under the

rear cockpit wall where the armored headrest is located. I don’t think this is

what I have seen from the MC.200 cockpit photos. I built the Special Hobby and

Italeri kits in parallel to assist in kit comparisons and when compared side to

side the CA cockpit tube was quite a bit longer.

I started

the kit per the instructions which are easy to follow and well done. It consists

of six steps starting with the resin cockpit, step “A” and all its etched bits.

Inserting the completed resin cockpit tub and mating it to the sidewalls was a

modeling challenge. There are no locator pins or guiding marks so you are left

to you own resolution of what goes exactly where when it comes to adding the

completed cockpit tub. There is an odd fit where the seat back goes under the

rear cockpit wall where the armored headrest is located. I don’t think this is

what I have seen from the MC.200 cockpit photos. I built the Special Hobby and

Italeri kits in parallel to assist in kit comparisons and when compared side to

side the CA cockpit tube was quite a bit longer. Step “G”

(which you will find in a sub-box with step “B”) is the addition of the tail

wheel and its supporting plastic roof. A very nicely detailed resin rear wheel

is provided. I attached part 13 to one fuselage side first securing the plastic

part # 13 with plastic glue. When it was hardened, the next day, I used some

clear epoxy to provide a stronger join and reinforcement for this part since I

thought it might separate once the kit fuselage halves were closed and weight

applied to the rear wheel.

Step “G”

(which you will find in a sub-box with step “B”) is the addition of the tail

wheel and its supporting plastic roof. A very nicely detailed resin rear wheel

is provided. I attached part 13 to one fuselage side first securing the plastic

part # 13 with plastic glue. When it was hardened, the next day, I used some

clear epoxy to provide a stronger join and reinforcement for this part since I

thought it might separate once the kit fuselage halves were closed and weight

applied to the rear wheel.  The

completed resin cockpit kept shifting when I tried to add it to the fuselage. I

was never 100% sure it was in the right place. There is a small diagram in the

instructions, step “S” that combined with the diagram for step “B” completes the

mating of the seat with its harness and resin cockpit tub.

The

completed resin cockpit kept shifting when I tried to add it to the fuselage. I

was never 100% sure it was in the right place. There is a small diagram in the

instructions, step “S” that combined with the diagram for step “B” completes the

mating of the seat with its harness and resin cockpit tub. and inserted

them in the area on the wing tips that had a small bulge. The Special Hobby

48033 kit has a better crafted wingtip light by the way.

and inserted

them in the area on the wing tips that had a small bulge. The Special Hobby

48033 kit has a better crafted wingtip light by the way. The Special

Hobby kit, # 48033 is also missing the prominent external valve pushrods. The

Italeri kit does a good job with this section providing the pushrods attached to

the front and rear of the engine crankcase along with the engine exhaust piping.

Also, looking at the museum aircraft it seems the wiring harness is behind the

engine and not in a ring at the front as is usually found in American radial

engines so it would not be accurate to add a wiring harness to the front end so

I believe the etched was intended to represent the pushrod sleeves.

The Special

Hobby kit, # 48033 is also missing the prominent external valve pushrods. The

Italeri kit does a good job with this section providing the pushrods attached to

the front and rear of the engine crankcase along with the engine exhaust piping.

Also, looking at the museum aircraft it seems the wiring harness is behind the

engine and not in a ring at the front as is usually found in American radial

engines so it would not be accurate to add a wiring harness to the front end so

I believe the etched was intended to represent the pushrod sleeves.  I initially

chose to model the plane from the 369th Squadriglia, 22nd

Gruppo Autonomo Caccia Terrestre, 1941 Stalino, Russia with the yellow cowl,

under wingtips and fuselage bands because it is very colorful. A profile of it

can be found on page 86 of the

I initially

chose to model the plane from the 369th Squadriglia, 22nd

Gruppo Autonomo Caccia Terrestre, 1941 Stalino, Russia with the yellow cowl,

under wingtips and fuselage bands because it is very colorful. A profile of it

can be found on page 86 of the  The C.200

has an unusual double pitot arrangement featuring a pitot rod on each wingtip.

The reason for this is one pitot is heated and the other is not. It also has an

unusual cranked upward step with a second small tube under the main tubular

component. CA faithfully reproduced this but it is in flat etched metal. I took

some guitar wire and attached the flat etched metal to it to improve

survivability of this part and also add a “3D” depth to the flat part. I glued

the etch to the guitar wire, added some CA glue to round it out and painted it.

Some C.200’s also appear to have two piece straight tubular pitot’s as well

which I rarely saw in wartime photos. This type of pitot, the simple straight

version is available with the QB48341 Quickboost MC.200 Saetta Pitot Tubes &

Antennas resin. I am not sure how many of these, the straight pitot rods, were

used compared to the cranked one but you will find them both appearing in the

Italeri kits with the cranked pitot on the early fuselage versions and the

straight one in the later version.

The C.200

has an unusual double pitot arrangement featuring a pitot rod on each wingtip.

The reason for this is one pitot is heated and the other is not. It also has an

unusual cranked upward step with a second small tube under the main tubular

component. CA faithfully reproduced this but it is in flat etched metal. I took

some guitar wire and attached the flat etched metal to it to improve

survivability of this part and also add a “3D” depth to the flat part. I glued

the etch to the guitar wire, added some CA glue to round it out and painted it.

Some C.200’s also appear to have two piece straight tubular pitot’s as well

which I rarely saw in wartime photos. This type of pitot, the simple straight

version is available with the QB48341 Quickboost MC.200 Saetta Pitot Tubes &

Antennas resin. I am not sure how many of these, the straight pitot rods, were

used compared to the cranked one but you will find them both appearing in the

Italeri kits with the cranked pitot on the early fuselage versions and the

straight one in the later version. The cockpit

is hardly visible since it is a small opening so don’t fret too much about the

inside appearance – just get the seatbelts and seat looking good and you should

be happy. I do hope to see others build this kit and the Special Hobby 48033

Aermacchi C.200 I serie “Bubble Canopy”,

The cockpit

is hardly visible since it is a small opening so don’t fret too much about the

inside appearance – just get the seatbelts and seat looking good and you should

be happy. I do hope to see others build this kit and the Special Hobby 48033

Aermacchi C.200 I serie “Bubble Canopy”,