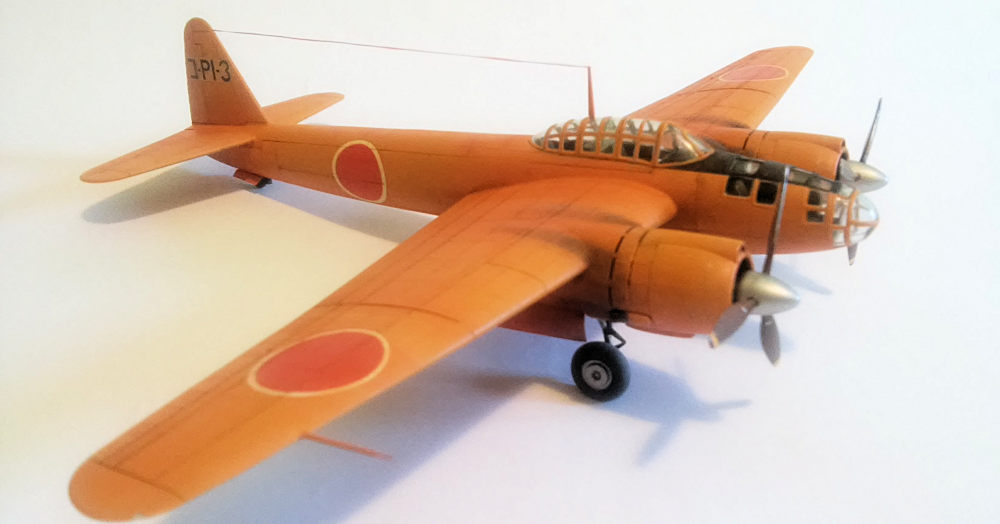

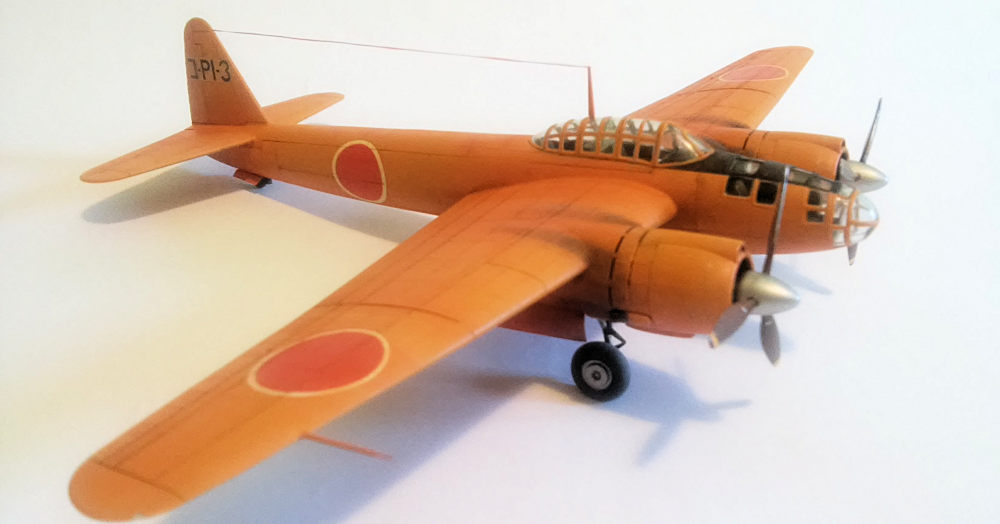

Revell 1/72 P1Y-1/2 'Ginga'

| KIT #: | H-103 |

| PRICE: | $ |

| DECALS: | Seven options |

| REVIEWER: | Andre Botto |

| NOTES: | Advantages: Simple kit, moderate parts count, good detail level, accurate in outline, alternative parts for 'Dash-1' or 'Dash-2' engine nacelles and windscreens. Disadvantages: 'Heavy' surface detailing; some fit issues; insufficient information on the versions involved; overlong landing gear parts (troublesome assembly process); 'bogus' interior; overly thick wing trailing edge and LG cover doors |

| HISTORY |

Unlike other WW2 belligerents, Japanese interest on

the fast, twin engine multi role attack bomber type came quite late. Early

Japanese Navy Air Force (IJNAF) operations were in the main the territory of the

'airline-like' G3M type 96 (Nell) and the ubiquitous G4M 'Hamaki' (Betty). It

was already 1944 when the concept did finally materialize in the form of the

Army's formidable Ki-67 (Peggy), while the IJNAF phased in its new P1Y-1 Model

11, poetically named 'Ginga' (Milky Way), but better known to the allies by the

TAIU reporting name 'Frances', this sometimes being shortened to 'Fran' in US

radio parlance (I'm using both designations interchangeably along this article).

A very sleek design, the Ginga is frequently compared to late model Ju-88s, but

its general arrangement and design philosophy may have been influenced by the

Douglas A-20, since some of them had been captured during the 1942 East Indies

campaign. The original 1940 specification called for a fast attack bomber,

capable of lifting the same bomb load as the Betty, while matching the

performance of a Zero fighter, with the help of two engines in the 2,000 HP

class, it being hoped the aircraft would surpass the 300-knot mark. A torpedo

carrying capability was also required.

In the face of the difficult international scenario, the traditional aircraft

manufacturers' teams were working almost to capacity, so the design was

entrusted to the Yokosuka Naval Air Arsenal, or 'Dai-Ichi Kaigun Koku Gijitsusho'

(shortened to Kugisho). Called design Y-20, it was the brainchild of a team led

by Engineers Masao Yamana and Tadanao Mitsuzi, resulting in an extremely sleek

design, sporting a narrow fuselage and a mid wing layout. The powerplant

selected was the new, 1820HP Nakajima 'Homare' (Honor), then still under

development. Unlike other types, crew complement (3 members) and defensive

armament were to be kept to a minimum: just a pair of guns, to be manned by a

bombardier/ navigator and an observer/gunner. Initially these were comprised of

a slow firing 20mm cannon in the nose and a dorsal rifle caliber machine gun,

but in practice there were several armament variations, according to the mission

profiles being flown. Later on, a pair of 13mm (.50), 'Type 2' MGs, whether on

single or twin mounts, were usually carried on bomber versions. Offensive

armament came in the form of a 800kg torpedo (carried with bomb doors partially

open), or two 500kg bombs (or various other combinations) in a ventral bomb bay.

The rest of the story is pretty well known... what happens when a new type,

however promising (He177, Typhoon, B-29, F-111... you name it!), is rushed

through production with a powerplant that's equally untried? Teething troubles!!

The prototype was flying by the summer of 1943 and test pilots (generally used

to fly more 'ho-hum' types) were at once full of praise for the plane's

nimbleness and speed (as high as 340 m.p.h.). And it even had pilot armour

plating! But the powerplant was another matter...

Although the test program was conducted with the help of the manufacturers'

experienced maintenance teams, the engines were a source of constant headaches,

with excessive wear and poor reliability; additionally, the overly complex

hydraulics was a source of numerous headaches. To compound the problem, the

production program was already in full swing. Initially, Nakajima's Koizumi

plant was selected due to the phasing out of Nell production, the production

lines being quickly dismantled to give way to Ginga production. The practical

result was that for practically one year, Air Force storage depots became full

of aircraft that had not yet been accepted for service use (such a sorry state

for a people so 'orderly-oriented' as the Japan ese).

By the time all the bugs had been ironed out, it was already late 1944 and the

scenario had changed considerably, with the Japanese now on the defensive and

being pushed out of all territories it once conquered. A new fearsome tactic had

been inaugurated, in the form of the Kamikaze attacks; Ginga's debut came about

at just such a time.

ese).

By the time all the bugs had been ironed out, it was already late 1944 and the

scenario had changed considerably, with the Japanese now on the defensive and

being pushed out of all territories it once conquered. A new fearsome tactic had

been inaugurated, in the form of the Kamikaze attacks; Ginga's debut came about

at just such a time.

The time is February, 1945, and the Japanese garrison on Iwo Jima had been all

but annihilated after a bloody battle with U.S. Marine forces, backed by a

powerful fleet. By early March, this had retreated and steamed back to Ulithi

Atoll to regroup, being discovered by a fast recon C6N1 Sayun (Myrt). Naval

headquarters quickly decided to exploit this situation and mounted 'Operation

Tan' a raid on the anchored ships. For this purpose a dedicated unit had been

formed on P1Y1s, the 'Asusa Special Attack Unit', which was to fly the

1,500-plus mile distance in a 'one-way' suicide bombing attack. In order to help

the bombers with the difficult navigational issues, support would be provided by

the Emily flying boats of the 801st Air Corps. The operation took place on

March, 11th, with 24 bombers taking off from Kanoya Air Base with bombs and fuel

for a one-way trip, initially being led by a lightened H8K2 flown by an 801st

AC's senior pilot. Later on, the lead was to be taken by two other Emilys (that

had taken off in advance), which were also charged with assessing the raid's

bomb damage.

However, by the time the formation reached Okinotori Shima, severe rain squalls

were encountered, forcing a descent into low level, where headwinds were

encountered, reducing groundspeed and increasing engine wear. Thirteen of the

bombers experienced engine problems and left formation; while most of them

managed to land on Japanese held Islands, two did ditch and were lost. Finally

Yap Atoll came into view, from which the run in into Ulithi could be ascertained

and the bombers parted company with the H8K2s at 18:52h, attacking in pitch dark

conditions up to 19:30h. The H8K2s did not observe any fires at all in the gloom

and Operation 'Tan' (including Ginga's performace) was deemed a failure. U.S.

records show that only USS Randolph was damaged in Ulithi that day. It had been

a complete failure.

This inauspicious beginning was not being helped by events in the Home Islands.

Meanwhile, appreciating the design's speed potential (as well as a backup should

something foul Nakajima's production), Japanese Naval Headquarters had

instructed Kawanishi for Ginga production in its Konan plant. For fear of the as

yet untried Homare, Kawanishi selected installation of the powerful Mitsubishi

Kasei 25a of 1,850HP, giving rise to the P1Y-2S version, 'romantically' named

Kyokko (Aurora), of which just 96 examples were to be produced. Armament was

once again revised, with deletion of the nose gun and installation of two Type

99 Model 2 cannon firing obliquely upwards. Once again a Frances version was

beset by troubles, since Kyokkos could not reach the B-29s' operational

altitudes for an effective interception, and the scheme fell through. Surviving

airframes had their oblique armament removed and reconverted to bomber

configuration (P1Y-2 Model 16s).

In the face of the desperate war situation, the Kamikaze special attack doctrine

was expanded, calling for the utilization of every aircraft type (and boat)

available, and the projected P1Y4 version was selected as the carrier ship for

the Ohka Model 22 jet powered suicide bomb, superseding the combination Betty/

Ohka 11 then in use. Mercifully, the Japanese surrender intervened and an

invasion of the Home Islands was avoided, to the general relief. None of the

subsequent Ginga versions, P1Y3, 4, 5 or 6 were ever built.

However, a lot of testing had already been carried out on jet propulsion

concerning the Ohka 22's engine ・called 'Tsu-11' - which was not quite what we

know as a jet nowadays, but a type of 'Campini engine' (today known as a 'Ducted

Fan'), in which the compressor section is not moved by a gas turbine, but rather

by a conventional piston engine. Since it wouldn't be possible to test it on the

bomb itself, here again the Ginga enters the tale, for one of the Homare

prototypes was quickly adapted as a carrier (a modification we'll call the 'Jet

Frances' on this article), in the same fashion as would later happen with

several other surplus bombers, like B-17s, Lancasters, etc. Its aft bomb bay was

adapted with a ventral bulge in which a Tsu-11 was installed. With 'two turning

and one burning', this combination must have been quite fast...

The rest of the tale must forcefully remain untold, for here come the end of the

information available. Instead of a respected opponent, most Gingas quickly

became one more type of 'fighter fodder', due to factors such as lack of

experienced pilots, poor manufacturing and maintenance practices and incorrect

tactical doctrine. Of the 1000-plus examples built, (fortunately) one example

survives (i.e., above sea level), having been brought postwar from Japan by

carrier and now stored in the Smithsonian's NASM restoration facility. The

airframe is reportedly incomplete and, with the museum's current philosophy of

preservation-instead-of-restoration, a restoration is unlikely in the near

future... if so, what a pity for this beautiful aircraft!!

Remember Tadanao Mitsuzi? After VE-day, and after changing his surname to 'Miki'

(a common occurrence in the sensitive climate of postwar Japan), he found a new

job with 'Japan National Railway' Company and was instrumental in the design

process of the new 'Shinkansen' fast train, one of the most visible symbols of

the postwar restoration of Japan's pride and also one of the country's most

famous postcard scenes with Mount Fuji as a background...

| THE KIT |

Now a trip down memory lane: according to the

'legend', the great Revell concern once spurred the appearance of several

'local' licensed kit Manufacturers abroad, such as in Germany (by far the most

successful), Britain and also in Japan, where several WW2 IJNAF and IJAAF types

were kitted, most notably Sally, Helen, Nick, Irving... and Frances. In a

practice now common, the moulds were periodically 'swapped' or leased between

different manufacturers and Brazil's Kikoler Company (of Rio de Janeiro) was a

case in point, having kitted batches of these three last types. I can still

remember the time when these could be found at hobby shops and were quite

expensive to acquire...

Fast forward to modern times: My favorite hobby shop was [unfortunately] holding

a foreclosure sale and I couldn't believe my luck when I saw copies of both the

Frances and Irving kits on sale!! After snatching them, I proceeded to

thoroughly examine my prize: Frances!! To me, simply one of the most beautiful

WW2 aircraft, period! Its box was the most damaged one and showed signs of

moisture damage, while it had already been started, so Frances goes first...

For modern standards, the kit is quite simple, only 70 numbered parts moulded in

three grey sprues and a clear one. surface detailing is of both raised and

engraved type, with rivets, but these are quite petite and delicate in form and

(unlike a lot of other contemporary kits) do not detract from the general

appearance. The engraved lines are heavier, but even then are far from looking

like 溺atchbox's trenches・

The kit's

greatest asset is that of alternate parts to represent both -1 and -2 versions;

these include full(!!!) engine parts (a lot of the expensive 1:48ths of today

just come with a flat 'look alike') and alternate cowlings for Homare and Kasei;

there are also alternate armoured and unarmoured windscreen parts.

The kit's

greatest asset is that of alternate parts to represent both -1 and -2 versions;

these include full(!!!) engine parts (a lot of the expensive 1:48ths of today

just come with a flat 'look alike') and alternate cowlings for Homare and Kasei;

there are also alternate armoured and unarmoured windscreen parts.

The instruction sheet is another beauty: yes, just ONE, single, 2-page sheet;

you haven't got to read a book in order to build this one...

There come decals and instructions for 7 versions, both -1 and -2, and one of

them is... Jet Frances!! Clearly drawn with the Tsu-11 engine fairing, however

there are no conversion parts or further comment on it...

In the ordnance dept., the bird is 'armed to the teeth' with a type 99 cannon in

the nose and an MG for the observer; this looks like a type 96 'Lewis look

alike'. There's also an open bomb bay to be 'decorated' with a 'Long Lance'

torpedo or 3 bombs... these look like one -500kg and two -250kg types. Two wing

drop tanks complete what comes as a respectable array for a vintage kit.

All doors and detail parts are overly thick and detract from the general

appearance; the antenna mast would be 'at home' in a square-rigger, while the

pitot probe looks like 40mm cannon barrel ・these have to be replaced!

An interesting note is that, as a result of the hydraulic system's teething

troubles, the tailwheel installation was revised and the originally retractable

tailwheel became fixed. The kit somewhat 'botches' things, since (overlong)

tailwheel doors are provided, to be glued around the 'fixed type' tailwheel

enclosure, which is just a circular hole from which the leg juts out.

A curious trait of old kits are the landing gear parts. Perhaps because

yesteryear examples were conceived to be put on 'display stands', LG legs were

moulded in the 'decompressed' (fully extended) oleo leg position, which only

happens in flight or when the bird is jacked up; a dry fit assembly will quickly

confirm that.

| CONSTRUCTION |

When reviewing the information available, I quickly

decided to go for the prototype... however, it was with much more reluctance

that I decided not to try scratchbuilding the Jet Frances. First, because if

you're building an IJNAF type other than Zeros and don't read Japanese, your

info sources are pretty limited.... in this case, just one (lousy), well known

photo of the contraption, which does not adequately convey the fairing's true

form. Furthermore, this seems to have some pretty complicated intake trunk

detailing. Second, because doing it would mean representing the aircraft in a

rather 'sorry state', with a lot of wear and tear (differently colored spinners,

etc.); so, I chose the 'backdating to an 'early version' option.

I'll skip the 'blow by blow' account in order not to get boring. Since we're

dealing with the prototype, the first step is to do away with all

armament/ordnance (and radar aerials), which is relegated to the 'spares

dungeon'.

The assembly process begins with... the engine nacelles!! Revell provides us

with four engines (eight rows of cylinders), to be mounted on a common back

plate incorporating the cooling gills and the production versions' ejector

exhausts. However, it is clear that the prototype, just like in the early Zeros,

had the 'manifold' type... so it's necessary to cut off and sand away all

exhaust stubs and rescribe the cooling gill engravings. I used the longer 'Homare'

cowlings, and these were intended to take the smaller engine parts. The

resulting test fit was not to my liking, since I found them quite anemic and

unlike the reference photos, so I chose to modify those (larger) parts originally intended for the Dash-2. These present

two problems, namely they do not have enough 'chord' and would place the

crankcase too far inside the cowling; secondly, the rows are devoid of any

rocker arm or control rod detail. The first one was easy to correct; I just

glued on a pair of unused (and ugly) 1:72 wheels to the back plate to serve as

spacers; the whole was then reinforced with tiny amounts of dental resin. The

second was more elaborate: armed with photos of the real thing, a minor

scratchbuilding effort was begun. First I filed away the lateral top sides of

each cylinder (front row only) and installed sprue bits to mimic rocker arm

covers; the next step was to install individual bits of tiny styrene rods, which

were anchored to the crankcase on small holes drilled with my smaller drill

bits... easier said than done, but it all came up all right. The propeller

mounting holes were then carefully re-drilled in order to accept the axes in a

snug fit ・it worked, and in the end it made possible for me to install them

without any gluing ・as a precaution against the 'odd idiot' who's frequently

around at contests and tries to see whether the propellers really 'spin'...

to modify those (larger) parts originally intended for the Dash-2. These present

two problems, namely they do not have enough 'chord' and would place the

crankcase too far inside the cowling; secondly, the rows are devoid of any

rocker arm or control rod detail. The first one was easy to correct; I just

glued on a pair of unused (and ugly) 1:72 wheels to the back plate to serve as

spacers; the whole was then reinforced with tiny amounts of dental resin. The

second was more elaborate: armed with photos of the real thing, a minor

scratchbuilding effort was begun. First I filed away the lateral top sides of

each cylinder (front row only) and installed sprue bits to mimic rocker arm

covers; the next step was to install individual bits of tiny styrene rods, which

were anchored to the crankcase on small holes drilled with my smaller drill

bits... easier said than done, but it all came up all right. The propeller

mounting holes were then carefully re-drilled in order to accept the axes in a

snug fit ・it worked, and in the end it made possible for me to install them

without any gluing ・as a precaution against the 'odd idiot' who's frequently

around at contests and tries to see whether the propellers really 'spin'...

The whole was then painted; it was then and there that I made my first mistake,

by choosing to paint all my elaborate work's results in flat black and

drybrushing the highlights in silver... since that's a closely cowled engine, in

the end the whole assembly became practically invisible behind the propeller...

only appearing when shining a strong flashlight through the aperture. Aha!! But

at least I know it's all there!! [We'd better stop proclaiming that aloud, lest

they decide to put us into a sanatorium, hee, hee!]

Then I chose to turn my attention to the interior parts; in this was helped by

the many photos available of the sole example extant. Here once again there was

some parts shuffling.

Engineering of the cockpit parts is quite out of the ordinary. To begin with,

it's a 'two-storey' affair, with an upper part to represent pilot/ observer

accommodations and a lower one forming the bomb bay top and the floor of the

bombardier's compartment. In their center portion, the two parts interlock to

form an open compartment into which the wing alignment tabs can later slide.

Kikoler's version comes without any crew figures. As commented, interior parts

are quite 'bogus', possibly a reflection of insufficient type information at the

time of the mould's design (today we can count with excellent info on that

subject!).

The detail parts themselves are an 'interesting' collection of vague forms that

seem to have been more or less fashioned out of guesswork. The space between

cockpits is occupied by a 'reserve tank' that's not present in the preserved

example. The crew's seats are all basic; add miniature 'legs' and they readily

become excellent doll house stools. The bombsight looks very much like a coffee

table and there are two other 'strange blocks', to be tucked inside the

bombardier's enclosure and become virtually invisible in the end; one is

L-shaped, while the other clearly resembles an old jukebox. There is a sizable

gap between the pilot's panel and the side consoles, quite unlike the full size

airplane.

My first step was to carefully saw away the 'tank' format, in order to only

leave a sort of wall between the two cockpits. In order to fill the space up, I

chose to glue on in its place the 'jukebox' form, that's going to mimic the

radio gear that would be present there; plastic card bits filled the remaining

gaps. The other problem was posed by the removal of the dorsal MG; this left off

an ugly open void that I had to fill up in some way. I finally decided to take

advantage of the 'two-storey' assembly and chose to reposition the whole upper

part a few millimeters back (although this had its consequences later on...);

the long instrument panel upper coaming allowed for that to succeed. I then took

the steps to close down the gap between this panel and the side consoles; this

was done with some bits of plastic blocks an sheet stock. The instrument panel

itself does not have enough gluing surface to 'stick', so I had to reinforce it

with a stout bit of sprue (that comes up completely invisible in the end). The

gap between panel and consoles was also filled up with plastic blocks.

I wanted to do something about the bombardier's enclosure also. As moulded, it

looks like a hermetic coffin, totally devoid of accesses. Of course that's not

true, for the BN entered the plane through a ventral hatch and could also use a

couple of 'skylight' upper doors to peer out over the nose (an arrangement

practically identical to the Tupolev SB's); I chose to replicate the former. To

do this, I just hacked off a rectangular opening in front of the BN's feet (of

course, I left off the bombsight) I later painted the fuselage parts underneath

black; although a little overdone, this helps highlighting the aperture's

presence.

I was not happy with the seats either, but decided that I was only to modify the

upper ones, since the BN's was smaller, more hidden and had less headroom to

spare. In this I was again helped by the reference photos available on one of

seats extant, which shows a semicircular back section and space for a backpack

parachute. I took the original pilot and observer seats and clipped away some

two thirds of each seat back, then filed them to a square topped format; the

next step was to sand away each back's corners, resulting in a 'rounded'

appearance when viewed from above (see photos). I then stretch formed ('heat and

smash' method) a couple of new rounded back parts of the adequate shape. What

remained of the original, uncut part of the seat back now looked like a support

for a backpack parachute ・just simple scratchbuilding!

The ensemble was then painted ・now, I know about the considerable argument there

is on the subject of Japanese interior finishes: the famous 'Aotake', or 'Young

Bamboo' color. I admit: I'm not an expert on the subject and neither do I want

to be. In this way, I just chose a color that mostly resembled young bamboo and

I saw it used on many Zero restorations (I know the color well, living in a

tropical country, and it most definitely does not look like a semi transparent

blue green, so I ignored it). In Mikesh's book that color corresponds to hue

A/N-34, so I just sprayed all interior parts uniformly with a home brawn mix I

made myself. The finishing touch were to add the seat belts, which I took the

poetic license to paint them a mid beige to add some contrast. The only

exception was the instrument panel, painted a very dark green.

These interior parts go very well together and are easily enclosed inside the

fuselage halves. However, I wouldn't say the same about bomb bay doors. In

practice, the bomb bay was conceived to be posed open, with doors that slide

into the fuselage (this option really calls for leaving the doors completely

off), but the 'prototype option' calls for a closed compartment, so get your

putty tube and be prepared for some filling... Here I'll open a parentheses to

the benefit of those aiming at the 'open doors' option: both bomb bay doors come

as a single part to be cut off and longitudinally split... on their aft

extremity they show a sort o deep groove... the photos I have seen of wartime

aircraft show that this line marks the division between the forward and after

sections... you've got it right: These are actually FOUR doors and, while the

forward ones slide inside, the aft ones actually OPEN OUTWARDS!! Well, you've

been warned!

As has been told elsewhere, the bird is covered with rivets, but these are by no

means of the old 'golf ball' size, being quite subdued. Some purists may

disagree from it, but in my assembly I chose to keep them as intact as possible

(a difficult thing considering the volume of sanding work that would soon be

coming) for that additional touch of 'vintage modeling'. In order to restore the

many lost rivets, I would use my new 'secret weapon': a super-duper Chinese

riveting apparatus! It worked, but all the 'new rivets' were engraved and looked

even more subdued...

Now begins a more 'boring' phase, that of adjustments, filling and sanding...

I'll discuss it in general terms: summing it up, while the Ginga is not quite a

'putty queen', it's quite 'putty intensive'; that's were the true modelers are

taken apart from the boys! Practically every part and joint had to be dry fitted

and gently 'convinced' to form a smooth bond with the one it was glued into. The

wing parts have quite thick trailing edges and have to be sanded down to a

thinner outline; I had to be careful not to obliterate too many rivets in the

process.

In order to get the least possible trouble, I chose to split up the bomb bay

door part in two and carefully glue each half to its respective side, then work

with just the seam down the centerline; to my chagrin, this resulted in a large

gap down the centerline, that had to be carefully filled, puttied, sanded,

refilled, sanded again, rescribed and re-riveted... Uf!!

Wing

joints in old kits are those notorious 'step-makers', and Ginga is no exception,

but this kit had a trait that actually helped me: the wing parts had only got

alignment tabs in the top halves! I quickly took advantage of it and subverted

the assembly sequence by first gluing the top ones on, taking special pains to

ensure good alignment and avoiding steps; if necessary, any differences were

dealt with by opening up the insertion grooves on the fuselage. I had also to be

careful not to interfere with the open space inside, since I had shuffled the

interior parts' position, remember? Once these had dried, I then glued the

bottom parts in the same fashion, thus achieving an almost perfect fit! The

resulting joints only needed minimum amounts of putty. Unfortunately this could

not be repeated with the single part stabilizer parts, and that joint gave me

more trouble and took more elbow grease to finish.

Wing

joints in old kits are those notorious 'step-makers', and Ginga is no exception,

but this kit had a trait that actually helped me: the wing parts had only got

alignment tabs in the top halves! I quickly took advantage of it and subverted

the assembly sequence by first gluing the top ones on, taking special pains to

ensure good alignment and avoiding steps; if necessary, any differences were

dealt with by opening up the insertion grooves on the fuselage. I had also to be

careful not to interfere with the open space inside, since I had shuffled the

interior parts' position, remember? Once these had dried, I then glued the

bottom parts in the same fashion, thus achieving an almost perfect fit! The

resulting joints only needed minimum amounts of putty. Unfortunately this could

not be repeated with the single part stabilizer parts, and that joint gave me

more trouble and took more elbow grease to finish.

I turned my attention back to the engine nacelles, this time to modify the

exhaust system to the manifold option. First I had to decide whether there would

be one or two exhaust outlets per engine; from the 2 photos there was simply no

way to know and (purely on guesswork) I finally chose to add two ('early Zero'

style), since it didn't seem to be enough exhaust area using just one manifold

exit. To do this meant blanking off two cooling gills per exit, these being

filled up and faired into

Here I used some left over parts from another kit, mainly a dreadful old 1:48th

P-51. To imitate the voluminous fairing in front of it, I sanded away one half

off the tip of a (badly moulded) 5・HVAR rocket and glued it in the front, while

the exhaust stub itself was replicated using a section of suitably sized

Contrail tube. The whole assembly was then puttied, sanded and finished.

A tale apart were the two overlong main landing gear legs. To complicate

matters, they have been engineered to be assembled together with the nacelles,

BEFORE the finishing process. This had to be so lved,

because I'd already broken the tailwheel off by trusting this system. The legs

were engineered to slide into oval- and round-shaped compartments. I simply cut

off the after part of the oval ones and this allowed me to install the legs

later (although that was quite a tense moment).

lved,

because I'd already broken the tailwheel off by trusting this system. The legs

were engineered to slide into oval- and round-shaped compartments. I simply cut

off the after part of the oval ones and this allowed me to install the legs

later (although that was quite a tense moment).

There are several ways to shorten the legs; I chose the more handsome and

accurate, but also the more difficult one, by severing the oleos themselves and

(carefully!!) also separating the sway braces. The parts were then drilled to

accept the new short oleos, made up of a stout copper rod inside another bit of

Contrail tube. The sway brace was then reglued in place. Golly, you've got to

take a lot of length out of it: practically 2 millimeters!! Wheels and tires

also called for attention; wheel hubs were drilled, detailed and glued to the

tires, which were then sanded down (no movable wheels on this one...)

Aileron and tail feather details came next; as moulded they are so deep, they

look like 'rice paddy dykes' full of the old - terrible - 'fabric effect'. It

was a bit of a chore, but I managed to fill them all with plastic sheet stock,

putty, sand and finish ・it looks much better now...

As told elsewhere, the prototypes sported a retractable tailwheel; to replicate

it, I carefully cut off the fuselage around the tailwheel mount, thus forming a

tailwheel well of suitable size (use your references); the overlong door parts

were then clipped in order to suit this size.

The wheel doors are also not good; besides looking like casemate hatches, fit

also suffers ・if the bomb bay doors seem to be made to be assembled open, these

are almost a perfect fit when closed! I simply did not want to stretch form a

new set of doors, so went about thinning them from the inside... some more elbow

grease!!

One of the model's finest points is the scribing showing the precise location of

all navigation lights; I took the opportunity and filed away these areas, then

glued bits of clear sprue that were then sanded and polished to shape to

represent the actual lights; the ones on the wings were small enough that I just

let them stay transparent, without color tinting.

With a lot of exposed framing, the clear parts are a little more challenging

than usual. I was a little worried at first but although not altogether good,

fit was quit decent, except for the pilot's windscreen (for the prototype

version, be sure to use the rounded one provided), which demands a little more

adjustment work, sanding and polishing. Also, go easy with the putty, in order

not to mar any parts.

For an

added realism touch, I chose to scratchbuild the 'auxiliary windscreen', which

was installed between cockpits in order to allow the 'in flight' opening of the

pilot's enclosure without disturbing the gunner's. It was simply fashioned out

of a piece of flat clear styrene cut, sanded, drilled and painted... but when I

was going to install it, I had another surprise: here again, my internal parts

shuffling had had its effects, for the cockpits' new boundary did not coincide

with the place where the windscreen should be. In the end, it had to be glued

one full frame back from that point. However, I just said: 'what the heck?' and

proceeded with it, for it's a really cool detail!

For an

added realism touch, I chose to scratchbuild the 'auxiliary windscreen', which

was installed between cockpits in order to allow the 'in flight' opening of the

pilot's enclosure without disturbing the gunner's. It was simply fashioned out

of a piece of flat clear styrene cut, sanded, drilled and painted... but when I

was going to install it, I had another surprise: here again, my internal parts

shuffling had had its effects, for the cockpits' new boundary did not coincide

with the place where the windscreen should be. In the end, it had to be glued

one full frame back from that point. However, I just said: 'what the heck?' and

proceeded with it, for it's a really cool detail!

| COLORS & MARKINGS |

Since everything was OK, it's now on to the paint

shop. The first step was to install the kit on a 'painting jig' ・I usually plan

in advance the way I'm going to rig that up, usually using the landing gear

attachment points as supports; it is worth the extra time spent on it, since it

provides an additional support and allow me to avoid having to touch the kit or

use clumsy gloves (a potentially accident prone condition).

Considering the kit's irregularities (rivets, etc.), I chose to apply a really

consistent primer coat, using Gunze Mr. Mark 1000. It got extra heavy on some

points, perhaps (it got a little exaggerated in the end...); in this case, the

sanding and repainting process took a bit longer, quite normal for a model this

age. I also discovered that having rivets on a kit is a bit of a liability

during the painting process, for you've got to work more carefully, especially

avoiding marring the surfaces with dust particles.

For the prototype version, the instruction plans called for a scheme of 'olive

green overall', but now we know differently, doesn't we, folks? Probably one of

the main reasons for my choice, many Japanese prototypes (look at Hasegawa's

'G8N Rita') were painted overall... trainer orange... and it must have looked

like a big orange!!

To paint the main coats, I elected to use 'AEROTECH PAINTS', a nitrocellulose

based line of paints originally conceived for automotive work; although of

excellent quality, drying fast to the touch and providing very thin coats, they

have quite a 'stink', so take care with the fumes...

Monochrome or (largely) single color finishes are a modeler's opportunity to

exercise 'multi-layer', or surface texturing painting, representing different

lighting conditions, weathered areas, wear & tear, etc., practically the same

reasoning used to paint model figures.

I consider

this my 'time of trial': most of us seem to feel quite at home with one tool,

while having a difficult time with another, and while feeling quite at home with

a brush in my hands (perhaps because I've been brought up this way), I always

approach airbrush tasks with some anxiety, since a mess-up here is usually very

costly. On forums I keep hearing about messy paintwork, glazed or cracked

varnish coats, etc. Well, with chemical factors aside, the only cause I can

think about for this boils down to the old five-letter word: HASTE!! The only

antidote known for that is that old P-word: PATIENCE!! According to that

philosophy, I really took my time and things turned into 'slow motion'; I chose

to allow for a lot of time ・sometimes up to two weeks ・between coats.

I consider

this my 'time of trial': most of us seem to feel quite at home with one tool,

while having a difficult time with another, and while feeling quite at home with

a brush in my hands (perhaps because I've been brought up this way), I always

approach airbrush tasks with some anxiety, since a mess-up here is usually very

costly. On forums I keep hearing about messy paintwork, glazed or cracked

varnish coats, etc. Well, with chemical factors aside, the only cause I can

think about for this boils down to the old five-letter word: HASTE!! The only

antidote known for that is that old P-word: PATIENCE!! According to that

philosophy, I really took my time and things turned into 'slow motion'; I chose

to allow for a lot of time ・sometimes up to two weeks ・between coats.

It began with the base coat. The chip shows that what we've called 'Trainer

Orange' is more of a Red Orange. For this I chose to go for my own, home-brawn

hue, by mixing quantities of basic orange with a very dark red paint. I

proceeded slowly and smoothly covered all surfaces. After that had proved surely

dry, I started adding the several texturing layers; in a very brief description,

that was begun by masking and spraying all 'fabric' control surfaces with a

contrasting, lighter hue. Third step consisted in spraying all upper surfaces

with a much lighter, yellowish tone. I'll explain: according to my experience,

the red pigment in the orange is one of most sensitive ones to sun bleaching, so

I really 'let'er rip' with the yellow mix above.

Major painting was then achieved by spraying the underside darker tones, with

special attention given to the engine nacelles and exhaust areas. The final

touch was then to paint the pilot's antiglare paneling on the upper nose (the

photos only showed paint in this area, so I left the cowling tops painted

orange).

A lot more days elapsed in order to let the layers fully cure. The whole was

then uniformly sprayed with liquid wax as a preparation for decaling; in this

case I used 'Tacolac' wax, diluted 50/50 with isopropyl alcohol.

The decal set was actually one of the biggest surprises I had. It was the kit's

the original set of 'Serigraphs' and I estimated their age to be in the 40-year

range; however, they had clearly been well stored (in a dry place), looked good

with just mild yellowing and were integral. Imagine my joy when all application

tests showed near perfect results!! And you still mumble about the low quality

of the local products!!

However, in the 'decal design' department all was not so good. The kit's set had

been conceived to fit the combat versions and sported fuselage hinnomarus

(meatballs) considerably smaller than the prototype's. Besides, I'd need white

surrounds on all six positions, while the underside ones provided were also for

green & gray painted examples. Decal spares to the rescue!! There were four

'red-only' meatballs to be used at the night bomber versions, and I used those;

meanwhile, I had located a sheet for another nation's roundels that sported

(extremely thin!!) separate white surrounds, and it was just a matter of

combining four designs from each set... and we are done! I was thus free to

apply those originally intended for the upper wings to the fuselage. This time

these are a little larger than needed, but the difference is not so noticeable.

I generally got really cautious about that and decided to use mild setting

solutions, opting for a local brand called 'DEC SYSTEM', but the most difficult

spots were dealt with minute amounts of Gunze's Mr. Mark. Here again, I

discovered that rivets are quite an issue when applying decals over them.

It all went perfectly well, except for the 'KO-P-I-3' (denoting Kugisho) tail

code and it's carrier film is the only one that really got quite noticeable,

especially after the weathering layers applied. I was already wary of too much

tampering with such vintage decals, so let it be that way. The finishing touch

came by applying the data table under the empenage, a 'trifle' originally

overlooked by 'toy manufacturers'... this was a small table listing data like

type, model, manufacturing date, engine type, etc., and this one had been

stencile d

over a small natural metal patch on the lower tail area. Conclusion: the bird's

garish coat had been applied 'after' the stencil's addition... To emulate that

involved a duplication effort: I had already masked and sprayed Alclad over a

small rectangular patch and then just apllied a small stencil table I took from

a 'Western' aircraft type' that I found after a frantic search... I'm risking my

salt that most contest judges will not be able to read 'Nippon-go' on a 1:72nd

data table under the plane's stabilizer, hee, hee!! The final protective varnish

coat was then applied.

d

over a small natural metal patch on the lower tail area. Conclusion: the bird's

garish coat had been applied 'after' the stencil's addition... To emulate that

involved a duplication effort: I had already masked and sprayed Alclad over a

small rectangular patch and then just apllied a small stencil table I took from

a 'Western' aircraft type' that I found after a frantic search... I'm risking my

salt that most contest judges will not be able to read 'Nippon-go' on a 1:72nd

data table under the plane's stabilizer, hee, hee!! The final protective varnish

coat was then applied.

Weathering is one of the parts I really enjoy in a kit (that's brush work!) and

I really 'let'er rip' with a whole range of techniques, applying oil paints

(shade & highlight), airbrushing 'Tamyia smoke' and a final pastel application.

Pitting and scraping was simulated with aluminum powder and a fine (expended)

felt tip pen; I kept my application confined to leading edges, prop tips, engine

nacelles, upper center section and canopy rails. As a reflex of the engine

trouble, photos show heavily pitted paint about the cowling panels, so these

received special attention.

Also as per the photos, landing gear parts were treated to a coat of flat

aluminum and then some areas were masked and painted black (a scheme only seen

on the prototype). These were later finally installed into the wells (an

exhilarating moment!) and I just added the doors without further ado (I didn't

add any other detail to the wells).

The only tasks remaining involved adding the final details. The rear canopy was

re-bored in order to receive a replacement antenna (more P-51 stuff), while the

new pitot probe was fashioned from a bit of copper wire inside a section of

hypodermic tubing; then added the antenna wire and with this I think this old

kit had already suffered enough in my hands.

| CONCLUSIONS |

After so many years of modeling, I know my audience well... if you are all still with me, now probably half the guys may be asking themselves just why I have chosen to build such a complicated 'oldie', while the other half may be mumbling just why I may have chosen to expend such a 'rare box'... Heck, that's because it's a beautiful plane!! There's only one other injected 72nd kit on the market (Hasegawa) and from a distance, my prototype will surely pass for one of them. And although being 'vintage', the Revell Frances is by no means 'venerable'. With a good bit of determination and that 'P-word', it's going to transform itself into a startling replica of the Shinkansen's forerunner!

| REFERENCES |

- 'Japanese Aircraft of the Pacific War', by Dr.Ren

Francillon. Putnam

- 'Camoufrage [sic] and Markings of IJNAF Fighters'. Bunrin-do

- 'Japanese Cockpit Interiors, vol2' (booklet) and 'Japanese Cockpit Interiors'

(hardback edition), both by Robert C. Mikesh. Monogram Books

- Several websites of WW2 IJNAF aircraft photos

31 May 2018

Copyright ModelingMadness.com. If you would like your product reviewed fairly and fairly quickly, please

contact

the editor or see other details in the

Note to

Contributors. Back to the Main Page

Back to the Review

Index Page

Back to the Previews Index Page