German Beaching Trolley

|

KIT #: |

- |

|

PRICE: |

Negligible |

|

DECALS: |

- |

|

REVIEWER: |

Carmel J. Attard |

|

NOTES: |

Materials required:

thin plastic card, metal wire, and wheels, sprue. |

On

occasions I come across modelers who are keen on building float planes and when

they come to display the model, quite often, they either display it standing on

the twin floats or display standing on a makeshift bracketed stand which is

custom made but not quite the design appropriate for the type.

Some

model kits such as the Japanese Sairan and Pete come with an accurate beaching

trolley and so does the single float type Ro-43 by Pavla Models and in such a

cases no problem of this sort exist. Other models like the Fairey Swordfish and

Sea Fox, Bellanca Skyrocket, Arctic Auster, Supermarine S6B, these would only

require drilling a hole right through at the correct place at the side of each

float, where a shaft is inserted and a set of wheels are added on which the

aircraft can be safely manoeuvred at some parking spot on the beach.

On

occasions I come across modelers who are keen on building float planes and when

they come to display the model, quite often, they either display it standing on

the twin floats or display standing on a makeshift bracketed stand which is

custom made but not quite the design appropriate for the type.

Some

model kits such as the Japanese Sairan and Pete come with an accurate beaching

trolley and so does the single float type Ro-43 by Pavla Models and in such a

cases no problem of this sort exist. Other models like the Fairey Swordfish and

Sea Fox, Bellanca Skyrocket, Arctic Auster, Supermarine S6B, these would only

require drilling a hole right through at the correct place at the side of each

float, where a shaft is inserted and a set of wheels are added on which the

aircraft can be safely manoeuvred at some parking spot on the beach.

Not

so can be said in the case of building models of German type of twin floatplanes

such as the Heinkel He-42, He-60, Arado 96, He-114 and Arado Ar-196 etc. etc.

Over the years I managed to find a solution to this situation involving these

types. I have managed to acquire a drawing of the type of beaching gear

involving the trolley used with additional proposal for a more sturdy type that

was used for the heavier floatplanes. The method of building these trolleys is

not beyond the reach of the many keen modelers in spite that they have to be

built from scratch. This is a relatively simple method that would certainly

yield satisfactory results. One of the trolleys which has a single bogie wheel

at the side was used for types as the He-42, He-51 and He-60 while another type

which was of a more robust construction had twin bogie to each side and was used

on Arado Ar-96 and Ar-196 types.

Not

so can be said in the case of building models of German type of twin floatplanes

such as the Heinkel He-42, He-60, Arado 96, He-114 and Arado Ar-196 etc. etc.

Over the years I managed to find a solution to this situation involving these

types. I have managed to acquire a drawing of the type of beaching gear

involving the trolley used with additional proposal for a more sturdy type that

was used for the heavier floatplanes. The method of building these trolleys is

not beyond the reach of the many keen modelers in spite that they have to be

built from scratch. This is a relatively simple method that would certainly

yield satisfactory results. One of the trolleys which has a single bogie wheel

at the side was used for types as the He-42, He-51 and He-60 while another type

which was of a more robust construction had twin bogie to each side and was used

on Arado Ar-96 and Ar-196 types.

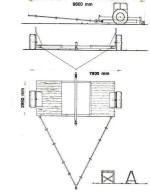

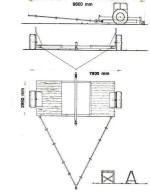

Arrangement

drawing of the simple type of beaching trolley is shown. The dimensions are in

‘mm’. The simple way to adopt them to 1/72 scale is obviously by dividing the

dimensions by 72. The result will be the standard measured length of the

dimension on a printed drawing layout. This will be used for constructing the

part items required. The material required is a pair of A5 size white plastic

card sheets, a pair of 20mm diameter bogie wheels, a pair of metal paper pins, a

length of 1.5mm metal wire and a short thick sprue piece. Once a full set is

produced then the trolley can be constructed using liquid cement and /or super

glue where metal is used.

Arrangement

drawing of the simple type of beaching trolley is shown. The dimensions are in

‘mm’. The simple way to adopt them to 1/72 scale is obviously by dividing the

dimensions by 72. The result will be the standard measured length of the

dimension on a printed drawing layout. This will be used for constructing the

part items required. The material required is a pair of A5 size white plastic

card sheets, a pair of 20mm diameter bogie wheels, a pair of metal paper pins, a

length of 1.5mm metal wire and a short thick sprue piece. Once a full set is

produced then the trolley can be constructed using liquid cement and /or super

glue where metal is used.

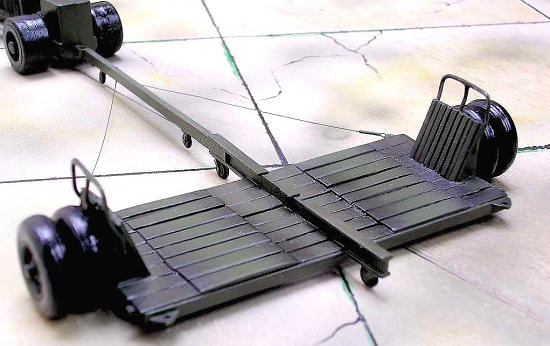

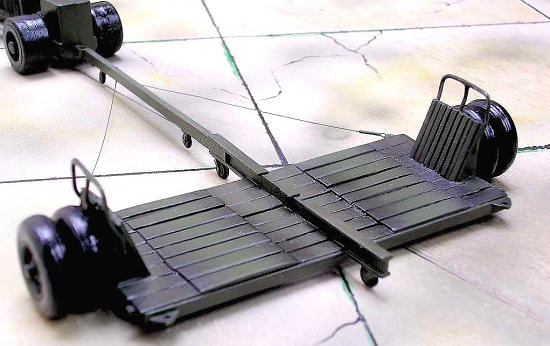

The

main component is a rectangular piece of plastic card, which had a square, cut

space at the centre. Strips of plastic card are cut to suite a dimension that

now forms the planking on the sides of the blank areas on the rectangular base.

Two smaller pieces form the mudguards. These had two sides made on the shape of

a right angle triangle. Another shaped items are cut to form the outside face of

the mudguards adjacent to the wheels. A hole is drilled at the base of the

mudguard and a shaft is inserted to take the 20mm diameter wheels. Other

construction d

The

main component is a rectangular piece of plastic card, which had a square, cut

space at the centre. Strips of plastic card are cut to suite a dimension that

now forms the planking on the sides of the blank areas on the rectangular base.

Two smaller pieces form the mudguards. These had two sides made on the shape of

a right angle triangle. Another shaped items are cut to form the outside face of

the mudguards adjacent to the wheels. A hole is drilled at the base of the

mudguard and a shaft is inserted to take the 20mm diameter wheels. Other

construction d etails

take the form of straight strips, which form the metal perimeter around the

trolley base. These were made in double, as the plastic thickness I used was

rather thin. The side metal frames fitted to the mudguards were made from metal

paper clips that seemed to offer the right thickness. These were bent to shape

and super glued in place. The long ‘Vee’ shaped metal pull strop was made from a

piece of wire with distance circular shaped pieces being constructed from cut

lengths of round sprue that were inserted at a distance apart. This apparently

held the tube away from the muddy floor. The end of the metal wire had a length

of 2mm bent down at 90 degrees. These will fit inside eyeholes located at two

front corners of the trolley. Segmented plastic strips formed a central beam and

at each end a smaller wheel added. These were tail wheels acquired from the

spares box.

etails

take the form of straight strips, which form the metal perimeter around the

trolley base. These were made in double, as the plastic thickness I used was

rather thin. The side metal frames fitted to the mudguards were made from metal

paper clips that seemed to offer the right thickness. These were bent to shape

and super glued in place. The long ‘Vee’ shaped metal pull strop was made from a

piece of wire with distance circular shaped pieces being constructed from cut

lengths of round sprue that were inserted at a distance apart. This apparently

held the tube away from the muddy floor. The end of the metal wire had a length

of 2mm bent down at 90 degrees. These will fit inside eyeholes located at two

front corners of the trolley. Segmented plastic strips formed a central beam and

at each end a smaller wheel added. These were tail wheels acquired from the

spares box.

A

more sturdy type of beaching trolley can also be constructed using same

dimensions with the difference that the robust construction had additional

planking at the base and also had a pair of wheels added at each side and the

trolley was pulled from a central beam of

‘I’ section as shown in the

drawing. A thin wire inserted in eyeholes at two corners of the trolley served

to keep the beam from swaying to one side when trolley is driven at tight

corners. The central beam also had 4 smaller wheels added which will serve to

hold the trolley level. A tractor model that I located in a Hasegawa Emily

flying boat appeared to fit the shape of tractor used with these types of

trolleys.

A

more sturdy type of beaching trolley can also be constructed using same

dimensions with the difference that the robust construction had additional

planking at the base and also had a pair of wheels added at each side and the

trolley was pulled from a central beam of

‘I’ section as shown in the

drawing. A thin wire inserted in eyeholes at two corners of the trolley served

to keep the beam from swaying to one side when trolley is driven at tight

corners. The central beam also had 4 smaller wheels added which will serve to

hold the trolley level. A tractor model that I located in a Hasegawa Emily

flying boat appeared to fit the shape of tractor used with these types of

trolleys.

Having assembled all the pieces together

the beaching gear is painted in shades of olive green simulating discolouring at

the area where the floats rest, possibly adding some wear and tear at this area.

For those who build

to a larger scale of 1/48, the same method is used with the difference being in

using thicker plastic card and other material sections, size of wheels etc.

Having

scratch built these pair of floats with satisfactory results one may now study

other large flying boats when beached and observe the type of trolley being

used. Careful examination may open scope for more research to be carried out so

that other trolleys designs can be built for specific types of float and

seaplanes.

Luftwaffe Seaplanes 1939-1945 by Chris Goss and

Bernd Rauchbach

Carmel J. Attard

November 2011

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review Index Page

Arrangement

drawing of the simple type of beaching trolley is shown. The dimensions are in

‘mm’. The simple way to adopt them to 1/72 scale is obviously by dividing the

dimensions by 72. The result will be the standard measured length of the

dimension on a printed drawing layout. This will be used for constructing the

part items required. The material required is a pair of A5 size white plastic

card sheets, a pair of 20mm diameter bogie wheels, a pair of metal paper pins, a

length of 1.5mm metal wire and a short thick sprue piece. Once a full set is

produced then the trolley can be constructed using liquid cement and /or super

glue where metal is used.

Arrangement

drawing of the simple type of beaching trolley is shown. The dimensions are in

‘mm’. The simple way to adopt them to 1/72 scale is obviously by dividing the

dimensions by 72. The result will be the standard measured length of the

dimension on a printed drawing layout. This will be used for constructing the

part items required. The material required is a pair of A5 size white plastic

card sheets, a pair of 20mm diameter bogie wheels, a pair of metal paper pins, a

length of 1.5mm metal wire and a short thick sprue piece. Once a full set is

produced then the trolley can be constructed using liquid cement and /or super

glue where metal is used.

etails

take the form of straight strips, which form the metal perimeter around the

trolley base. These were made in double, as the plastic thickness I used was

rather thin. The side metal frames fitted to the mudguards were made from metal

paper clips that seemed to offer the right thickness. These were bent to shape

and super glued in place. The long ‘Vee’ shaped metal pull strop was made from a

piece of wire with distance circular shaped pieces being constructed from cut

lengths of round sprue that were inserted at a distance apart. This apparently

held the tube away from the muddy floor. The end of the metal wire had a length

of 2mm bent down at 90 degrees. These will fit inside eyeholes located at two

front corners of the trolley. Segmented plastic strips formed a central beam and

at each end a smaller wheel added. These were tail wheels acquired from the

spares box.

etails

take the form of straight strips, which form the metal perimeter around the

trolley base. These were made in double, as the plastic thickness I used was

rather thin. The side metal frames fitted to the mudguards were made from metal

paper clips that seemed to offer the right thickness. These were bent to shape

and super glued in place. The long ‘Vee’ shaped metal pull strop was made from a

piece of wire with distance circular shaped pieces being constructed from cut

lengths of round sprue that were inserted at a distance apart. This apparently

held the tube away from the muddy floor. The end of the metal wire had a length

of 2mm bent down at 90 degrees. These will fit inside eyeholes located at two

front corners of the trolley. Segmented plastic strips formed a central beam and

at each end a smaller wheel added. These were tail wheels acquired from the

spares box.