|

KIT: |

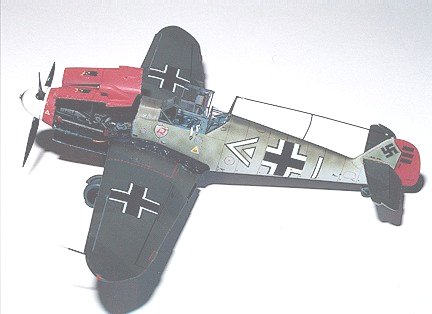

Hasegawa 1/48 Bf-109F-2 |

|

KIT # |

9126 |

|

PRICE: |

$ |

|

DECALS: |

See Review |

|

REVIEWER: |

Matt Swan |

|

NOTES: |

Verlinden kit #1302 ME109G-2 Tropical super update,

and #1367 Ground Crew; gun cleaning. |

|

HISTORY |

Willey Messerschmittís BF109 and all itís variants has always been fascinating to me and Iíve built several models of them over the years. Produced in 1941, the F model was a stopgap measure to combat the latest mark Spitfire, as the G models were not ready for production yet. Many German pilots felt that the F model or Franz was the best dog fighter of all the variants. This was also the first variant to use the cantilever elevators and eliminate the elevator support struts. The Franz's top speed exceeded the BF109E by a large margin and it had an excellent climb rate but like all 109ís, in a high speed dive the elevator would lock up and the only way to recover was to frantically adjust the elevator trim wheels Ė some real pucker factor here, especially if youíre being shot at.

|

THE KIT |

(Matt didn't provide any specifics on the kit or what comes in the box. Check out one of the many previews on Hasegawa 109s to get a general idea of what is included. Ed)

|

CONSTRUCTION |

For the basic kit I started with Hasegawaís BF109F-2

#09126 and Verlinden kit #1302, which is a detail kit for a 109G-2. The only

modifications required for the F-2 is to remove several small scoops from the

hood and nose cowling, which was accomplished with my trusty Dremel (best

Christmas gift I ever got!). These areas were touched up with 200 grit emery

clothe from my local auto parts store and then some 400 grit to polish. This

works very well and gives a good finish when complete.

For the basic kit I started with Hasegawaís BF109F-2

#09126 and Verlinden kit #1302, which is a detail kit for a 109G-2. The only

modifications required for the F-2 is to remove several small scoops from the

hood and nose cowling, which was accomplished with my trusty Dremel (best

Christmas gift I ever got!). These areas were touched up with 200 grit emery

clothe from my local auto parts store and then some 400 grit to polish. This

works very well and gives a good finish when complete.

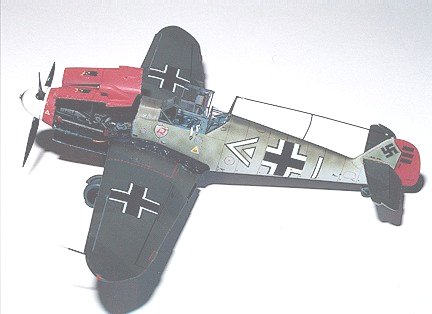

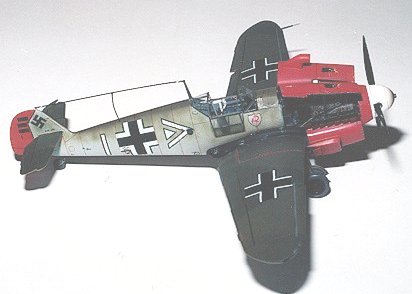

I started by examining the directions and pieces for both kits for several hours to develop a construction plan. I made notes on the kit directions to avoid forgetting details later on. The entire nose section needed to be removed from the fuselage and the gun cover has to be removed from in front of the canopy. The Verlinden instructions recommend leaving the Hasegawa gun cover in place if the hood is not going to be completely removed but it seemed that a gap would be created at the gun deck so I modified the parts somewhat and used the Verlinden pieces. The rear section of the gun deck needed to be cut down about 2mm and the inside of the gun cover has a ridge that must be removed from the rear section only. Several dry fits are needed to get this right. Once the fuselage halves were glued together with Tenax 7R the resin pieces fit in very nicely. The access panel under the wing had to be removed also. I have a welders tip cleaning drill that I picked up at the local welding supply shop for about $3.00 and it includes several bits in the handle, an invaluable tool. I used my welding tip drill to start a hole in the panel then carefully opened it up with the Xacto knife After the major pieces were removed with the Dremel, I cleaned everything up with diamond needle files.

After an intensive study of Edward Shackladyís book Messerschmitt BF109 I decided to leave the ailerons and rudder alone but to drop the elevators. Pictures of 109ís in the field show the elevator either raised or dropped while at rest and it seemed to be pretty evenly split. The Hasegawa elevators are of excellent quality and show the wood and fabric structure as well as the Verlinden but the kit trim tabs were better defined. Using a fresh Xacto knife to score both sides of the elevator joint allowed me to drop them with some firm pressure without completely removing them. A little Tenax 7R locked them in place.

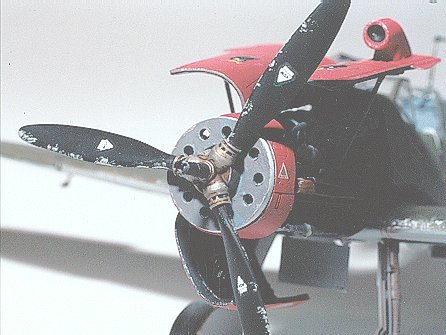

All radiators had to be opened up, the front scoops on the wing radiators were removed and the rear flap on the cowl radiator was removed. This was done with an Xacto knife. Care must be taken on the wing openings to not damage the areas that will remain. Itís a tight fit. The brass parts from the Verlinden kit replaced these. The Verlinden kit is an excellent kit with high-grade resin parts. I found only two air holes out of forty some odd pieces and they were in concealed areas. The brass was also excellent and can be trimmed with a razor knife. The DB601 engine built up according to specs with the addition of some wire from an old computer joystick cable for spark plug wires. These must be installed prior to the exhaust stacks going on. The engine firewall and gun deck were prepainted with Testors 1163 flat gray and installed in the fuselage. The rear sections of the MG131 guns are installed and then the gun cover can be glued in place. This entire area gets a black wash to create the effect of accumulated engine oil and spent gunpowder. I find that adding a little Future floor wax to the wash helps out a lot.

Next came the cockpit tub. The

Verlinden trim wheels sit too close together so a shim must be placed in-between

them or it will blend into one wheel. The chains running from the trim wheel

were a big disappointment as most of them were missing so I replaced them with

fine steel wire, didnít matter because you canít see them when complete anyway.

Verlinden provides two options for the 20mm cannon, with or without the cover. I

elected to build with the cover off since the aircraft would be displayed as

being serviced.

Next came the cockpit tub. The

Verlinden trim wheels sit too close together so a shim must be placed in-between

them or it will blend into one wheel. The chains running from the trim wheel

were a big disappointment as most of them were missing so I replaced them with

fine steel wire, didnít matter because you canít see them when complete anyway.

Verlinden provides two options for the 20mm cannon, with or without the cover. I

elected to build with the cover off since the aircraft would be displayed as

being serviced.

The wheel wells have to be opened up as the kit comes with round openings and the F-2 had sharp corners on the outside edges. The brass inlays from Verlinden were too tall to fit properly in the wheel wells and took extensive trimming to fit right. I cut them down with flush cutters then trimmed the rough areas with my Xacto knife. Even after that, putty was needed to finish it off. This was probably the most difficult piece of conversion work. The front area of the wing had to be thinned around the access panel prior to attaching the brass framework. The Verlinden radiators were installed after all interior areas of the wing were done in the Testors flat gray and then the tops were attached. All plastics were assembled with Tenax 7R.

The overall cockpit was painted with Testors 1163 and I picked out details with black, yellow and red enamels. A black wash was dropped into the instrument faces. Everything was dry brushed with steel to highlight the wear areas. The side panels were dry brushed with flat white over the steel. The dash was painted with Gunze Sangyo dark gray and dry brushed with white, yellow and red. I used the kit gun site in favor of the Verlinden site Ė it just looked better to me. Once the tub was installed in the fuselage I attached the completed wing assemble. The upper seat belts were not installed until the very end; I like the way they are casually draped over the cockpit wall.

I think itís important to note that I did not need to use any putty at any plastic-to-plastic joint. The Hasegawa parts mate up really well. Some putty was needed at the joint between the gun cover and the canopy.

|

CAMOUFLAGE & MARKINGS |

After cleaning up the glue joints and wiping the kit down with a micro sheen cloth, I donít like to wash with soap whenever possible, painting began. The micro sheen cloth will remove any oils and dust. It will even clean out most panel lines with a single wipe. Itís also great for when you get that big greasy fingerprint on your paint job. The rudder, upper and lower hoods and front cowling were sprayed with Gunze Sangyo RLM 23 red using a Badger 150 airbrush and an IL medium tip. The rudder was masked off after drying. The underside was painted with Gunze Sangyo RLM 76 light blue, the wheel wells with RLM 75 gray and the lightening holes with Testors flat black. The kit wheels were replaced with True Details #48006 and 1mm fuse wire was applied to simulate brake lines running down the front side of the gear struts. I used some foil from a wine bottle to make the tie down straps on the brake lines. The thin strips of foil were attached with a small spot of CA then wrapped around the strut and tacked again with CA. I like to use old dental picks for this kind of work because it gives me excellent reach into some really tight places and I can deposit the minimum amount of glue needed to do the job. Next time youíre at the dentist ask if he has any old picks, most do and are willing to give them away.

I masked off the cockpit and firewall area with

Stick-To-It from Darice. This is normally used to hang posters on the wall but

is great to work with for masking. Simply roll it out and apply it for the

camouflage pattern and cover the interior area with masking tape. Once itís

removed you have a finely feathered edge. The entire fuselage was sprayed with

RLM 76 light blue. RLM 82 light green was used to create the molted pattern on

the fuselage then over sprayed with RLM 81 brown violet on the top most surfaces

only. RLM 81 was applied to the wing surface. After this dried for a few hours I

laid on the Stick-To-It and masking tape then sprayed RLM 83 dark green to

finish the splinter pattern. Make sure to spray from directly overhead to

prevent a paint ridgeline from forming. Flat black was applied at the wing

root; this was a fairly common application on earlier 109ís to hide the exhaust

pattern. (Please send all e-mails regarding color and camo to Matt at his

e-mail. I know that he used a lot of non-typical colors on this kit, but that

was his choice as it is his model. Ed)

I masked off the cockpit and firewall area with

Stick-To-It from Darice. This is normally used to hang posters on the wall but

is great to work with for masking. Simply roll it out and apply it for the

camouflage pattern and cover the interior area with masking tape. Once itís

removed you have a finely feathered edge. The entire fuselage was sprayed with

RLM 76 light blue. RLM 82 light green was used to create the molted pattern on

the fuselage then over sprayed with RLM 81 brown violet on the top most surfaces

only. RLM 81 was applied to the wing surface. After this dried for a few hours I

laid on the Stick-To-It and masking tape then sprayed RLM 83 dark green to

finish the splinter pattern. Make sure to spray from directly overhead to

prevent a paint ridgeline from forming. Flat black was applied at the wing

root; this was a fairly common application on earlier 109ís to hide the exhaust

pattern. (Please send all e-mails regarding color and camo to Matt at his

e-mail. I know that he used a lot of non-typical colors on this kit, but that

was his choice as it is his model. Ed)

Now weíre going to have some fun, itís time to attach the engine and there is no structural guideline to mount it correctly. First dry fit the upper mounts to the firewall and visually check the alignment: left, right, up, down, do it twice. File off small amounts from the engine mounting until the alignment appears good. It took two or three adjustments with the Dremel using a small burr bit to the backside of the engine to get everything to seat properly. You will be able to adjust the up/down alignment slightly when the lower engine struts are put in. Do that next. I found that the front cowling was forward about 2mm so that the hood would not mount correctly and I had to remove the front radiator tank and sand it down to get the fit right. Once this has been accomplished I connected the final radiator lines from the lower rear engine into the wing root and added the MG131 gun barrels.

The spinner plate, prop blades and 20mm cannon barrel are assembled, painted and mounted to the front of the cowling. I applied a little brown wash to the pitch controls in the propeller hub; you donít want to get any of the wash on the spinner back plate. I drilled out the spinner cover so that the cannon barrel would hold it snuggly but could still be removed. Donít forget to drill out the cannon barrel. The Hasegawa propeller blades had to be shortened about ľ inch to achieve the proper length when complete. Take care that each blade is at the same pitch as the alignment studs get cut off in the shortening process. At this point I installed the lower engine cover with some CA+.

After allowing 24 hours for everything to dry down the entire model was coated with Testors gloss coat and allowed to dry again. The kit decals are pretty good but I had to add several stencils from Third group sheet #48-005. The squadron badge and prop emblems came from this sheet. This is the only manufacture I have found that includes the prop markings. Two different markings were occasionally used, an inverted triangle or a logo that looked very similar to the Hamilton Standard logo found on American aircraft. The kill markings for the rubber were printed in the same red as the paint job so I had to cut down a different decal from the kit sheet that was done in black. Great care must be exercised with the Hasegawa decals when using setting solution. I just about freaked when I applied Micro Sol and the decal edges started to curl up. This seemed to happen on the larger decals only.

|

FINAL CONSTRUCTION |

After another day of drying time I used a brown Micron C1

pen to highlight the panel lines, Micron 001 black pen for ailerons and rudder

demarcation and silver paint on a chopped brush for paint chips. Tamiya smoke

X-19 was used for gun and stack exhaust. I changed tips on the airbrush to an

extra fine for the smoke markings and when doing the light green molting on the

fuselage. I applied a Vandyke brown wash on the landing gear struts and doors.

Once more to the paint booth for a coat of

Testors dull coat lacquer and on to

the canopy. I like to do my own masking vs. using precut masks even if it is

tedious. First a coat of Testors flat gray was applied to give interior color

and then RLM 81 brown violet was applied. Every picture of a 109 cockpit that

Iíve seen clearly shows support struts in the upper corners of the front

windscreen. I was surprised to find that Verlinden did not catch this item but

it didnít take long to remedy with some odd bits of brass.

Testors dull coat lacquer and on to

the canopy. I like to do my own masking vs. using precut masks even if it is

tedious. First a coat of Testors flat gray was applied to give interior color

and then RLM 81 brown violet was applied. Every picture of a 109 cockpit that

Iíve seen clearly shows support struts in the upper corners of the front

windscreen. I was surprised to find that Verlinden did not catch this item but

it didnít take long to remedy with some odd bits of brass.

The canopy was attached with Testors clear parts cement. The canopy retaining spring was made from some of that joystick wire wrapped around a needle to create the spring look. Invisible thread was used for the antennae and painted over. A little CA was used for the insulators and the top engine hoods with support rods are attached. The support rods were cut from some scrap resin rod.

Thereís about 80 hours of work but weíre not done yet, Iíve still got to built a base and cover for display but thatís another project.

February 2003

|

REFERENCES |

Messerschmitt BF109 by Edward Shacklady

Cockpit by Donald Nijboer and Dan Patterson

Aviation History Sept. 2001

Fighters-Best of Flight Journal Summer 2001

Luftwaffe Fighter Modeling by Geoff Coughlin

The Battle of Britain by Richard T. Brooks

If you would like your product reviewed fairly and quickly by a site that has well over 175,000 visitors a month, please contact me or see other details in the Note to Contributors.

Back to the Reviews Index Page