Moebius1/25 Lone Star

| KIT #: | 1300 |

| PRICE: | $79,99 SRP |

| DECALS: | One option |

| REVIEWER: | Robert Myers |

| NOTES: | Shop for the best price as some retailers over-price the kit. |

| HISTORY |

| THE KIT |

This

1/25th scale kit is huge! There are over 300 parts and none of them are

individual track links! With the addition or deletion of the sleeper

roof extension (1 part), you can build two versions. The sprues are all

wrapped in plastic, very detailed and are very well molded without

visible injector pin marks or flash. The engineering of parts and parts

placement on the sprues really shows a modeler was involved with the

design on this one. Most of the sprue attachment points are hidden or

very small. Even the chrome is well thought out so that you donít have

major seams or attachment point cuts showing. The exceptions are the

fuel tanks

and air cleaners. They have a long seam where the halves

join. The upside is that the seam on the fuel tanks is hidden when you

add the aero skirts. The tires are soft vinyl and appear very realistic.

The parts also include a thin metal, flexible metal mesh grill insert.

This is a very nice touch.

and air cleaners. They have a long seam where the halves

join. The upside is that the seam on the fuel tanks is hidden when you

add the aero skirts. The tires are soft vinyl and appear very realistic.

The parts also include a thin metal, flexible metal mesh grill insert.

This is a very nice touch.

The

decals are bright and in register. They will be used to add woodgrain to

the interior, a nice dashboard, various exterior markings and a trucking

company name. Your choice

for company names are Erb, a real Canadian company, and Moebius

Transport.

There is

a downside to this kit; the instructions for building the engine are very

poor. They show a couple of color shots of the engine (great for reference)

and use text to tell you to add the parts. If you are not familiar with the

Maxxforce 15 engine it is a real trial. I would suggest you use the

instructions from a Revell Lonestar or a Moebius Prostar to build the

same engine, these instructions were great with exploded drawings. The rest

of the instruction sheet is just ok, with color call-outs for the parts on a

separate page. I copied the color callout page, so I didnít have to flip

back and forth in the instructions. (I would suggest going to the Revell web

site and downloading a set of their instructions. The kit is the same except

for decals.)

| CONSTRUCTION |

To

begin the assembly I broke it down into several steps, engine, chassis,

interior and cab/sleeper. Everything was washed in dish soap, and given

a good rinse. Donít skip the wash! There is a lot of mold release agent

on this kit and it will mess up your paint and leave visible finger

prints on the chrome.

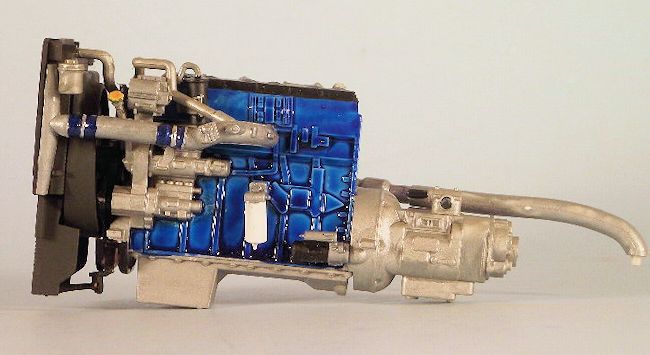

The

engine is a modern International Maxxforce 15 with EGR. International

discontinued this engine and replaced it with a Cummins, rather than

certify it for newer emission standards.

I would have like to see a Cummins engine in the kit, but I

understand the licensing problems. The engine was sprayed an appropriate

blue and assembled per instructions. The Moebius instructions are

confusing, but with a lot of test fitting everything is an excellent

fit. I went back with brush paint and did the detail painting. Chrome

foil was used to make the hose clamps. The finished assembly was given a

black wash and set aside to dry.

The

engine is a modern International Maxxforce 15 with EGR. International

discontinued this engine and replaced it with a Cummins, rather than

certify it for newer emission standards.

I would have like to see a Cummins engine in the kit, but I

understand the licensing problems. The engine was sprayed an appropriate

blue and assembled per instructions. The Moebius instructions are

confusing, but with a lot of test fitting everything is an excellent

fit. I went back with brush paint and did the detail painting. Chrome

foil was used to make the hose clamps. The finished assembly was given a

black wash and set aside to dry.

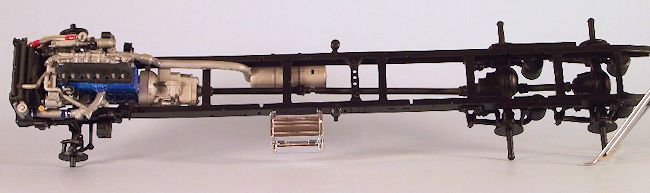

The

chassis was next. Before you start; figure out a way to insure you

assemble the frame rails and cross pieces so that everything is square!

I use a small carpenterís square taped to the glass on top of my work

bench. I check the fit often and when the basic assembly of frame and

cross pieces is complete, I stop and work on something else until the

glue is dry. Next, I added the rear suspension and differentials. There

are no surprises here, everything has an almost snap kit tightness to

fitting the parts. I followed the instructions and part numbers very

closely, for a change. There are parts that must go in a front/back or

left/right position for everything to line up. I assembled the front

springs and axle per the instructions, but I didnít glue one side of

the

axle to the spring. When you insert the engine you will be very happy

you did this, it saves a lot of fitting, bad language and possible

broken parts. No chrome parts were added to the chassis and it was set

aside to dry and wait for painting.

the

axle to the spring. When you insert the engine you will be very happy

you did this, it saves a lot of fitting, bad language and possible

broken parts. No chrome parts were added to the chassis and it was set

aside to dry and wait for painting.

This

interior is exceptional! Everything was prayed with Krylon grey primer

before assembly. The dashboard was detailed with paint. I thought it

looked pretty good, then in the spirit of doing a build review, I added

the decals. They feel a little thick, but I applied them over a drop of

Microset then brushed a little Microsol on top. The decals settled down

very well on the uneven dash board. It looks so much better than my hand

detailing. A little scraping on the join areas and the whole thing was

glued together. Again the assembly was almost a snap fit. The dashboard

was masked off and a final coat of grey primer was sprayed on. Some

small details were picked out with a brush and the rest of the wood

grained interior decals

were added directly to the primer coat. I trimmed them very close and

used Microset. They didnít silver and settled down nicely.

The

cab/sleeper is huge and intimidating and very well molded. The cab roof is a

separate part that has the glue joins along the same seams as seams on the real

truck. I glued the roof on and sprayed the cab, hood and fenders in black Krylon

primer. The fenders were sprayed gloss black and after drying the headlights

were installed. Beautiful fit. The intimidating part is all of the lights on the

lower cab. After spraying the cab Krylon grey, chrome foil was applied to the

lower cab/sleeper before installing the lights. Each depression for each light

was given a prep drop of turn signal amber paint. When that was dry, I inserted

a clear lense into each depression. Each lense was given a coat of turn signal

amber to glue it into place. Extra lenses are included, but I didnít loose any.

My installation technique was to wet the tip of my finger, touch the outside of

the lense and just press it into place.

were installed. Beautiful fit. The intimidating part is all of the lights on the

lower cab. After spraying the cab Krylon grey, chrome foil was applied to the

lower cab/sleeper before installing the lights. Each depression for each light

was given a prep drop of turn signal amber paint. When that was dry, I inserted

a clear lense into each depression. Each lense was given a coat of turn signal

amber to glue it into place. Extra lenses are included, but I didnít loose any.

My installation technique was to wet the tip of my finger, touch the outside of

the lense and just press it into place.

The final

assembly was easy. All of the chrome and bright parts were glued to the chassis

and cab. The engine was fitted to the frame and the front axle was glued to the

spring. I used epoxy to glue the floor of the interior to the chassis. This is a

heavy model and someone will pick it up by the sleeper. I can see the chassis

dropping off at the worst possible moment. Hence the epoxy. The assembly for the

interior and cab is unique. The instructions have you glue the floor to the

chassis, then slip the cab in place over the interior. It worked, but if I

hadnít used epoxy on the floor/chassis mounts, I know I would have broken the

floor loose from the chassis. On my next build, I will glue the interior into

the cab first, then mount the whole thing on the chassis.

The hood was

fitted. It fits close, but not quite what I would like. After looking at the

Moebius test builds on line and talking to one of the builders, I saw they had

the same problem on multiple builds. So I decided if all of those very good

builders couldnít get it straight, it was close enough for me.

| COLORS & MARKINGS |

I sprayed all of the major parts with Krylon primer and paint. I used Model

Master brush paints for all of the detailing. There were no reactions

between the two. I didnít use the decals for the outside of the truck, as I

am having my own decals made for a series of these trucks, in my own company

name. I can tell you the decals on the inside worked well and reacted very

well to Microsol and Microset. If I may nag a bit; donít forget to wash all

of the parts, prior to priming/painting.

I sprayed all of the major parts with Krylon primer and paint. I used Model

Master brush paints for all of the detailing. There were no reactions

between the two. I didnít use the decals for the outside of the truck, as I

am having my own decals made for a series of these trucks, in my own company

name. I can tell you the decals on the inside worked well and reacted very

well to Microsol and Microset. If I may nag a bit; donít forget to wash all

of the parts, prior to priming/painting.| CONCLUSIONS |

This was a

long (3 month), but enjoyable build of a modern truck! Moebius is honest and

rates this kit as a skill level 3. Bottom line this is not a kit for a beginner

because of the instructions, but it

is a very detailed and easy build of a new subject for the average to

experienced builder (if you use Revell instructions). I have now bought six of

these kits because the kit itself will build into two different sleeper versions

and I am doing a daycab, a wrecker and of course I need a spare for who knows

what. So, yes, I highly endorse this as a well done kit!

This was a

long (3 month), but enjoyable build of a modern truck! Moebius is honest and

rates this kit as a skill level 3. Bottom line this is not a kit for a beginner

because of the instructions, but it

is a very detailed and easy build of a new subject for the average to

experienced builder (if you use Revell instructions). I have now bought six of

these kits because the kit itself will build into two different sleeper versions

and I am doing a daycab, a wrecker and of course I need a spare for who knows

what. So, yes, I highly endorse this as a well done kit!