Airshow Models 1/32 Christen Eagle II

|

KIT # |

CE 1 |

|

PRICE: |

$85.00 |

|

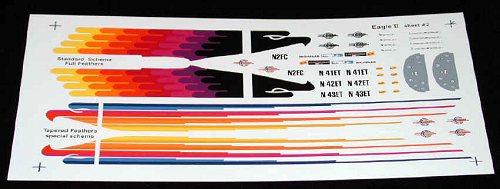

DECALS: |

See review |

|

REVIEW & |

Barney Dunlevy |

|

NOTES: |

Resin with metal parts |

|

THE KIT |

When I heard about Peter Groves' new Eagle kit, I was eager to see what he had

come up with and when we met for lunch, I was very impressed with what I saw.

Peter had asked me to do a construction article on the Eagle and to do a photo

shoot outside of his old hangar at Delta Air Park...how could I say no!

He provided me with a kit,

which contained some very good looking castings in brass, white metal, and

resin. The decals, which make the Eagle an outstanding subject, cover most of

the aircraft so painting would be at a minimum; White airframe, black tires and

a simple but detailed interior.

He provided me with a kit,

which contained some very good looking castings in brass, white metal, and

resin. The decals, which make the Eagle an outstanding subject, cover most of

the aircraft so painting would be at a minimum; White airframe, black tires and

a simple but detailed interior.

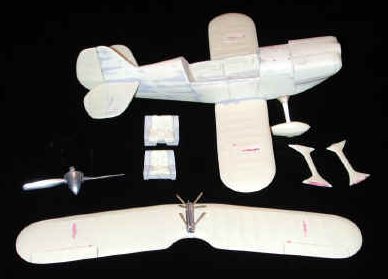

The fuselage consists of one casting with very fine scribed panel lines and

slightly raised stringers, with a deep cockpit. The cowling is cast as a one

piece unit with a fairly large casting plug on the back. This was the biggest

bit of resin that had to be sawn off with a fine-tooth saw. The upper and

lower wings are both one piece

with alignment slots for the struts. The rudder and horizontal tail components

are scale thickness with all flying surfaces having nicely detailed ribbing.

lower wings are both one piece

with alignment slots for the struts. The rudder and horizontal tail components

are scale thickness with all flying surfaces having nicely detailed ribbing.

The landing gear consists of brass gear legs, which fit perfectly into slots on

the fuselage ahead of the wings, and wheel pants with treaded tires molded in,

which are also slotted for the lower gear legs. The tail wheel is a jewel of a

brass casting with a small lug, to be inserted into a slot in the lower

fuselage.

Initial trial fitting of the components indicated few if any problems. Because

of the size and weight of the major parts, I would recommend that 5 Minute Epoxy

be used as an adhesive; particularly the engine cowling and lower wing. The

epoxy will give you time to align the parts for a more accurate fit and if you

have any excess squeeze out it can be removed with rubbing alcohol on a

Q-tip...making a better fillet at the joint.

The cabane struts, three brass V-units which are numbered (with No1 to the

front), fit into a slot in the bottom side of the upper wing, then covered with

a white metal fairing which makes up the center section of the strut system.

The spinner and propeller blades are cast white metal with very good detailing

on the spinner. The two exhaust stacks are also cast in white metal.

The cockpit consists of two seats with cast-in safety harness, an instrument

panel for the front seat, two throttle quadrants and two canopy locking panels.

There are also two brass control columns and a couple of canopy handles and

cross member for the canopy. This last item is vacu-formed with a spare...just

in case.

|

CONSTRUCTION |

For a large

number of resin castings, there are very few pinholes...only 7 in my copy. The

resin components were sanded to clean up a bit of flashing then the lower wings

and horizontal tail, were epoxied in place along with the main gear legs and

tail wheel. The lower wing -to fuselage joint required a piece of .010 plastic

card to fill the gap. After the glue cured it was easy to trim the excess

plastic with a new scalpel blade. The engine cowling was then epoxied in place

and then sanded to finish the installation. The main gear wheel pants was glued

in place with epoxy and the trailing edges of the wheel pants were blocked up

with 1/8 inch balsa strip to ensure proper alignment with the model sitting on

its wheels.

For a large

number of resin castings, there are very few pinholes...only 7 in my copy. The

resin components were sanded to clean up a bit of flashing then the lower wings

and horizontal tail, were epoxied in place along with the main gear legs and

tail wheel. The lower wing -to fuselage joint required a piece of .010 plastic

card to fill the gap. After the glue cured it was easy to trim the excess

plastic with a new scalpel blade. The engine cowling was then epoxied in place

and then sanded to finish the installation. The main gear wheel pants was glued

in place with epoxy and the trailing edges of the wheel pants were blocked up

with 1/8 inch balsa strip to ensure proper alignment with the model sitting on

its wheels.

The lower wing was marked for the landing wires and these were pre-drilled as

were the landing gear fairings, to ensure that the photo etched steel wires

would be installed without sagging. The I-struts were temporarily installed into

the slotted wing surfaces then traced around the base with a scribing tool. This

was to ensure that when painted and

decaled, this area could be

removed for the final assembly of the upper wing and struts, providing a good

bonding surface.

decaled, this area could be

removed for the final assembly of the upper wing and struts, providing a good

bonding surface.

The model was given a coat of Mr. Surfacer and a final light sanding in

preparation for painting.

The canopy was cut free and carefully sanded to fit the cockpit, then the white

metal cross piece was attached to the canopy. The cockpit was then detailed with

the instrument panel, throttle quadrants and canopy handles. The seats were

painted as per C-FPNB, Peter's old aircraft. With all the pieces in the cockpit,

the canopy was masked using fine tape and Micro Scale liquid mask. When this

dried the canopy was glued over the cockpit

with MS Krystal Kleer.

The propeller blades and

spinner are cast in White Metal with good details. These were polished using

Autosol Chrome polish. The blades were then painted Flat Black on the rear

surface and Flat Medium Grey on the front.

The propeller blades and

spinner are cast in White Metal with good details. These were polished using

Autosol Chrome polish. The blades were then painted Flat Black on the rear

surface and Flat Medium Grey on the front.

With the paint dried, the blades were inserted into the spinner with super glue.

The blades were given a light brushed coat of Polly Scale Gloss Clear and the

decals applied, followed by a flat coat to seal and finish the blades.

|

PAINT & DECALS |

With the canopy now installed it was time to get on with painting. Polly Scale

Flat White was used as both a primer and final colour coat followed by three

light coats of Polly Scale Clear Gloss. This was completed prior to installing

the upper wing and the flying and landing wires. Now the moment I've been

waiting for...those beautiful big decals. But the devil struck big time...the

Polly scale reacted with the resin, presumably, causing big yellowish spots. The

acrylic paint was quickly removed with Windex and the model was given two light

coats of Floquil White Enamel Primer, followed by three light coats of Model

Master Gloss White enamel.

The decals were then applied

starting with the bottom side of the stabilizer and upper and lower wings. These

went down without a problem and due to the thickness of the inks, a coat of

Solvaset was applied and the wait was on. The upper surface decals were now

applied, being careful to align the colours at the leading edge. The fuselage

now received the decals, with a cutout for the horizontal tail. Aircraft

registration letters were made up from clear decal paper and Letraset rub-down

letters and applied to the rudder and underside of the left wing. Not

surprising, the Eagle is registered C-FPNB, Peter Groves' old Eagle II which is

based at Boundary Bay, my home airport.

The decals were then applied

starting with the bottom side of the stabilizer and upper and lower wings. These

went down without a problem and due to the thickness of the inks, a coat of

Solvaset was applied and the wait was on. The upper surface decals were now

applied, being careful to align the colours at the leading edge. The fuselage

now received the decals, with a cutout for the horizontal tail. Aircraft

registration letters were made up from clear decal paper and Letraset rub-down

letters and applied to the rudder and underside of the left wing. Not

surprising, the Eagle is registered C-FPNB, Peter Groves' old Eagle II which is

based at Boundary Bay, my home airport.

With the decals finished, it was time for final assembly. Remove the decal film

from the wing strut mounting slots and test fit the cabane struts and the

interwing struts. The brass and white metal pieces in the cabanes took a lot of

fitting and filing and when I was

satisfied , I drilled out the

six holes on top of the forward fuselage and attached the struts and fairing.

The upper wing was laid flat and 5 minute epoxy was applied to the groove in the

bottom of the upper wing and the slots for the I-struts. The fuselage was

inverted and the struts were inserted in the slots. Take care here because the

I-struts are beveled both top and bottom and can only fit properly in one way.

The model is designed to be self- aligning and sure enough when the epoxy cured

the Eagle was perfectly set up.

satisfied , I drilled out the

six holes on top of the forward fuselage and attached the struts and fairing.

The upper wing was laid flat and 5 minute epoxy was applied to the groove in the

bottom of the upper wing and the slots for the I-struts. The fuselage was

inverted and the struts were inserted in the slots. Take care here because the

I-struts are beveled both top and bottom and can only fit properly in one way.

The model is designed to be self- aligning and sure enough when the epoxy cured

the Eagle was perfectly set up.

The photo-etched brace wires were next. I had pre-drilled the attach points and

the wires just dropped into place and secured with super glue. The aileron and

rudder fittings were next glued in place with super glue and the tail wheel

springs were installed...my only add-on to a completely satisfying model.

Editor's note: I've been asked a number of times about getting this kit, but I believe that Airshow Models is out of business so check the usual auction sites.

Copyright ModelingMadness.com

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.

Back to Reviews Page 2020