Encore 1/48 F-102 Delta Dart

| KIT #: | 48001 |

| PRICE: | $60.00 'used' |

| DECALS: | Two options |

| REVIEWER: | Tom Cleaver |

| NOTES: | Reboxed Monogram kit with extras. Superscale 58-958 decals. |

| HISTORY |

What became the F-102 marked a major change in design and development of fighters. It was the result of a recommendation made on October 8,1948, by the Air Force Senior Officers Board that the service organize a competition for a new interceptor that would enter service in 1954; on February 4, 1949, the USAF approved the recommendation and announced a competition to be held in 1950 for what was then called the "1954 Ultimate Interceptor." In November 1949, it was decided the new aircraft would be built around a fire-control system (FCS) that would be designed before the airframe to ensure compatibility; the project became known as a “weapon system.

Air Materiel Command issued request for proposals regarding the fire control system in January 1950 to 50 companies, of which 18 responded. In May, the list was reduced to ten, which were reviewed by the Air Defense Engineering Committee. Following recommendations by the committee, the proposals were reduced to two competitors, Hughes Aircraft and North American Aviation. Hughes was chosen to develop the fire control system on October 2,1950.

An RFP for the airframe

was issued on June 18, 1950; six manufacturers

responded in January 1951. On July 2, 1954, Convair, Republic and Lockheed were

awarded contracts for a mockup. Convair based its proposal on the company’s

previous work designing and flying the XF-92 delta wing research aircraf, In

November, Convair was awarded a contract to devlop its Model 8-80 as the

“XF-102" as the airframe component of "Project MX-1554". In the end, Convair

emerged as the victor with its design,

An RFP for the airframe

was issued on June 18, 1950; six manufacturers

responded in January 1951. On July 2, 1954, Convair, Republic and Lockheed were

awarded contracts for a mockup. Convair based its proposal on the company’s

previous work designing and flying the XF-92 delta wing research aircraf, In

November, Convair was awarded a contract to devlop its Model 8-80 as the

“XF-102" as the airframe component of "Project MX-1554". In the end, Convair

emerged as the victor with its design,

Originally, the design was to be powered by the Allison J-40, which turned out to be the worst turbojet design in US aviation history. Fortunately, Pratt and Whitney’s marvelous J-57 arrived on the scene just in time. Continued delay in the MA-1 fire control system to the decision to go with an interim aircraft using the simpler E-9 fire control system as the F-102A, while the fully developed MA-1 system would be used in the F-102B that would be powered by the Curtiss-Wright J67, licensed derivative of the Bristol-Siddeley Olympus, This ultimately became the F-106A.

The prototype YF-102 flew for the first time on at Edwards AFB on October 23. 1953; it was lost in an accident nine days later. The second proototype flew on 11 January 1954, confirming that transonic drag was much higher than expected, making the airplane permanently suibsonic with a mximum speed of Mach 0.98 with a maximum ceiling of 48,000 feet, far below what was required.

Convair was saved by the publication of Richard Whitcomb’s “area rule”

for supersonic flight design. Adopting the rule, the XF-102's fuselage was

lengthened by 11 feet and "pinched" at the midsection with two large fairings on

either side of the engine nozzle, giving the airframe what was soon popularized

as the "Coke Bottle configuration" with revised intakes and a ne w, narrower

canopy. A more powerful model of the J57 was fitted, and the aircraft structure

was lightened. Additionally, the wing was redesigned to be thinner with

increased span. The leading edge was given a conical droop, with the apex at the

root, to improve handling at low speeds. Because the droop remained within the

shock cone of the leading edge, the drag rise at supersonic speeds was minimal.

w, narrower

canopy. A more powerful model of the J57 was fitted, and the aircraft structure

was lightened. Additionally, the wing was redesigned to be thinner with

increased span. The leading edge was given a conical droop, with the apex at the

root, to improve handling at low speeds. Because the droop remained within the

shock cone of the leading edge, the drag rise at supersonic speeds was minimal.

The first revised prototype, designated YF-102A flew 118 days after redesign began, on December 20, 1954; the next day it exceeded Mach 1. Further testing demonstrated a top speed of Mach 1.22 and a maximum ceiling of 53,000 ft. When the YF-102As successfully intercepted a B-36 at its maximum altitude, Convair’s improvements were deemed sufficient for the Air Force to authorize production of the F-102 in March 1954.

Production F-102As were equipped with the Hughes MC-3 fire control system, later upgraded to the MG-1, armed with six AIM-4 Falcon missiles divided between infrared homing 9AIM-4A)and semi-active radar homing (AIM-4D) variants. Unfortunately, the Falcon was the worst AAM the Air Force developed; fortunately, the F-102A’s opponent - Soviet intercontinental nuclear bombers - didn’t exist. Total production of 889 F-102As was completed in September 1968.

The F-102A first entered service in 1956 with the 327th FIS at George AFB. They were deployed throughout the continental US in ADC, in Europe with USAFE and the Pacific with PACAF by 1960. In 1964, F-102As were deployed to DaNang, South Vietnam, to provide air defense against possible attack by VPAF Il-28s. The aircraft were also used in ground attack and to escort B-52s. One was shot down by a VPAF MiG-21 using an Atoll missile on February 3, 1968. Two were shot down while conducting CAS missions, four were blown up by VC sapper teams, and eight were lost to engine failure and other operational accidents. Air National Guard units operated F-102s between 1965-76, when the aircraft left service for modification as full-size drone missile targets.

| THE KIT |

Monogram first released their 1/48 F-102A with the “Case X” early wing

in 1990. The kit was re-released in 1995 with the Case XX wing under the

ProModeler label. Re-releases of the Case XX model happened in 2000, 2002, and

by Revell in 2004 and 2016. In 2010, Squadron released an “Encore” kit with the

kit plastic and resin sets for the cockpit, control surfaces and missiles.

Monogram first released their 1/48 F-102A with the “Case X” early wing

in 1990. The kit was re-released in 1995 with the Case XX wing under the

ProModeler label. Re-releases of the Case XX model happened in 2000, 2002, and

by Revell in 2004 and 2016. In 2010, Squadron released an “Encore” kit with the

kit plastic and resin sets for the cockpit, control surfaces and missiles.

The F-102A has been released in 1/72 by Hasegawa in the 1960s with a kit that is quite primitive by modern standards, and by Meng released a Case X wing F-102A in 2012, followed the next year by a Case XX wing kit. This is fully up to modern standards.

Numerous aftermarket decal sheets were released over the years for the Monogram kit. After Monogram’s 2–4 release, which included decals for the California ANG 196th FIS, SuperScale released a sheet with both Case X and Case XX F-102As of that unit in 2010 at the time of the Encore release.

| CONSTRUCTION |

Monogram kits are famous for being simple in construction design,

and this kit is no different. Fit has always been an issue, however. With

this kit, the main fit problem is in the fit of upper and lower wing parts,

since the lower part fits into the curved leading edge which is on the upper

part. I found that by sanding the interior of the lower part and carefully

test-fitting that I could get the fit sufficiently tight that only a bit of

filler was needed. After sanding it smooth, I rescribed the detail that had

been lost. I also did this with fitting the fuselage halves together; I was

able to sand the inset right side to the

point it fit without need of

filler.

point it fit without need of

filler.

With these Encore kits, much of the resin isn’t useable. That was the case with the flaperons, which were not of sufficient span. I therefore kept the plastic parts and opted to sand them down to a proper trailing edge. I did use the rudder with the vertical fin.

The resin cockpit tub was useless, being too wide to fit without a lot of grinding down, I opted to stick with the plastic part and use the resin instrument panel and coaming, which meant I had to cut out the coaming on either fuselage half. The photoetch instrument panel was a definite improvement from the kit part. I combined the resin and plastic of the control stick, using the resin upper part mated to the plastic base. The resin ejection seat was a vast improvement and I used it without problem.

I used the plastic nose cone since the resin part was mis-shaped and

also a bit small in diameter to the fuselage. This allowed me to put weights

inside the cone; with some additional weights inside ahead of the cockpit tub

and wheel well, the model became a guaranteed nose-sitter.

I used the plastic nose cone since the resin part was mis-shaped and

also a bit small in diameter to the fuselage. This allowed me to put weights

inside the cone; with some additional weights inside ahead of the cockpit tub

and wheel well, the model became a guaranteed nose-sitter.

The fuselage and wing sub-assemblies came together without problem and I only had to use some filler for the lower rear fusealge wing/fuselage joint.

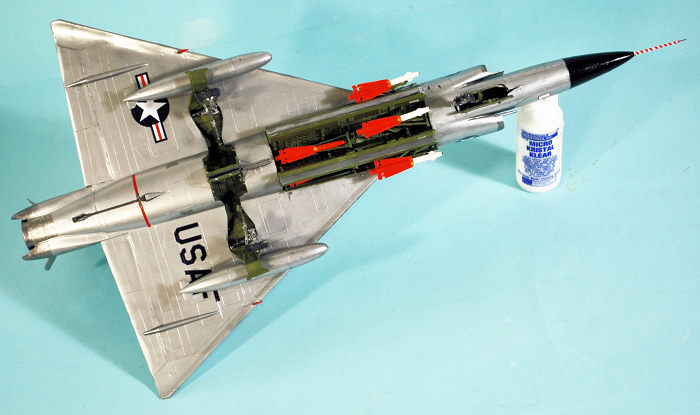

I decided to use the open weapons bay due to the fact the plastic option for the closed doors didn’t fit well. I cleaned up the plastic launchers and went with the resin missiles, which again were a vast improvement on the kit part.

| COLORS & MARKINGS |

When I read the decal instructions which stated that the Case XX wing option for the 196th FIS was painted overall aluminum lacquer, I wasn’t sure of that, However, when I asked google to show me photos of 196th FIS F-102A, the first three color photos showed the aluminum callout was correct.

I gave the model an overall primer coat of Tamiya X-18 Semi-gloss Black,

then masked off the radome and the weapons bay, and gave the model an overall

coat of Vallejo Semi-Matte Aluminum, which looked perfect after it dried. I

painted the exhaust area with Vallejo Dark Aluminum and the leading edge of the

intakes with Vallejo Duraluminum.

I gave the model an overall primer coat of Tamiya X-18 Semi-gloss Black,

then masked off the radome and the weapons bay, and gave the model an overall

coat of Vallejo Semi-Matte Aluminum, which looked perfect after it dried. I

painted the exhaust area with Vallejo Dark Aluminum and the leading edge of the

intakes with Vallejo Duraluminum.

The Encore kit decals are printed by Cartograf and were excellent. I combined the two sheets, using the national insignia and US Air Force and USAF decals from the kit sheet since they were the correct shade of dark blue, with the SuperScale sheet used for the 196th FIS markings and serial number. I also used the SuperScale stencil decals.

I used the resin wheels for the landing gear, which I then assembled and attached. I attached the drop tanks and positioned the canopy in the raised position. I attached the parabrakes in the open position.

| CONCLUSIONS |

The model came out much better than expected. It’s unlikely that another 1/48 F-102A will come along soon, and if it does it will be much more expensive than the old Monogram. However, Monogram’s Century Series make up into good kits if one takes time and treats the parts like they were a limited-run kit. I’ve liked the F-102A since I was a kid, and this is a good addition to the collection.

6 May 2021

Copyright ModelingMadness.com. All rights reserved.

Review kit courtesy of my wallet, thanks to the modeler who never got A Round Tuit, so I could buy if from the Estate Sale.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.