| KIT: | Kinetic 1/48 F-84F Thunderstreak |

| KIT #: | 4801 |

| PRICE: | $24.95 |

| DECALS: | Two options |

| REVIEWER: | Tom Cleaver |

| NOTES: |

| HISTORY |

The Republic F-84F was about as much an F-84 as an F-86 Sabre was an FJ-1 Fury. Yes, it saw its birth on the same design table, and the same designer - Alexander Kartveli - was present at its birth, and it was born at the same place, Republic Aviation. But past that the only thing it had in common with its Thunderjet forbear was an appetite for runways on takeoff.

Following the success of the swept-wing F-86 Sabre in 1947, the Air Force revised the General Operational Requirement originally issued in September 1944 that had resulted in the development of the F-84 Thunderjet. The revision called for significant increases in operational performance over that contained in the original document. The result of this would be one of the greatest corporate boondoggles in the history of the American aviation industry, in which corporate political influence and the perceived need to create a new weapon for an unanticipated war would result in an airplane finally delivered to first line units just in time to be sent to second-line service.

The F-84F officially began life with a letter proposal in November 1949 in which Republic Aviation suggested it could satisfy the revised GOR by modifying the straight wing F-84 with swept wing and tail. Republic modified the proposal within a month, with an offer to build additional ordnance capability into the new aircraft. While the drawings called the new airplane the F-96, Republic stated that the proposed low-cost new aircraft would merely be a modification of the F-84E then entering the USAF inventory, with 55 percent of the F-84E tooling utilized for the new aircraft. The Republic proposal was initially endorsed in December 1949 and Republic was allocated one F-84E for use in developing a prototype of the swept-wing aircraft. The Air Force, insisted the F-96 be redesignated, officially becoming the F-84F on September 8, 1950. This was an entirely political move on the part of the Air Force, to convince the Congress that this was not a new aircraft program, but merely a continuation of one previously authorized and funded. The name "Thunderstreak," the result of a contest among Republic employees, was given the new airplane.

The YF-84F prototype arrived at Edwards AFB in May 1950. Both the contractor’s Phase I tests and the Air Force Phase II tests, which ended that November with 64 flights totaling 70 flying hours demonstrated conclusively that the Allison J-35-A-25 engine’s 5,300 pounds of thrust was insufficient to give the airplane the performance required under the revised GOR. Both Republic and the Air Force agreed on modifying the F-84E fuselage to take the more powerful British Sapphire jet engine developed by Armstrong-Siddeley, for which Curtiss-Wright had acquired a manufacturing license. Production of the Wright YJ-65 would not begin before September 1951, which was the first indication that the F-84F would not be an easily-produced “minor modification” to the existing design. In November, 1950, the Air Materiel Command recommended two additional prototypes be built to evaluate the F-84F and Sapphire combination. The now quite-different F-84F design had its wings and tail swept at 40°, and used press forgings in the wing structure instead of built-up components, and an irreversible power-boost control system. Rather than the standard sliding canopy, the new aircraft had an upward-hinged canopy. As with the F-84G Thunderjet, the air refueling inlet nozzle was located in the left wing. To be powered by the Wright J65W-3 turbojet engine, rated at 7,220 lbs. of thrust, the F-84F carried the standard F-84 armament of four .50 caliber machine guns in the nose and two in the wing roots. The new airplane could carry heavier ordnance loads than the F-84G, with which it shared the ability to carry an atomic bomb, while two 450-gallon external tanks could be carried for long-range fighter escort missions.

With the Korean War now in full cry and the straight-wing Thunderjet having shown itself incapable of carrying out its long range bomber escort mission in the face of opposition from the more advanced MiG-15, the Air Force ordered the F-84F into full production before the new prototypes could be built and tested with the Sapphire engine, and also ordered the opening of a second source of production for both airframe and engine. The Buick-Oldsmobile-Pontiac Assembly Division of General Motors in Kansas City was selected to produce the F-84F airframe in January 1951, one month after the production go-ahead, while the GM Buick Division was also selected as the second source for the Sapphire engine. This contract was for 274 F-84Fs, and was amended during 1951 to eventually cover the production of 719 F-84Fs, with substantial price increases over the initial cost of $215,035.27 per aircraft; the final price being approximately $750,000 per aircraft following the failure of the GM production line to produce combat-worthy airplanes without substantial modification. (Who says there’s no social welfare in America and that failure is never rewarded?) Two other contracts were issued in Fiscal Year 1952 and Fiscal Year 1953, but the number of aircraft ordered was drastically reduced in later years. Since the F-84F was officially a production modification of the F-84E, no development contract preceded any of this. Despite knowing that the YJ-65 engines would not be available until at least September 1951, Republic signed a contract on March 22, 1951 that called for delivery of the first production F-84F in December 1951.

While Republic had promised at the outset that 55 percent of the tooling of the F-84E would be used in the F-84F, in fact the two types had only a 15 percent commonality. The first big production problem encountered was a shortage of aluminum alloy that - once available - could not be processed since only three presses in the United States could actually produce the aluminum wing spar and rib forgings for the F-84F, and these were fully occupied with producing forgings for the B-47, which had a higher production priority. Additionally, unexpected difficulties were encountered in the Americanization of the engine where again - contrary to expectations - the scarcity of machine tools which had been diverted to higher priority programs was a major problem until April 1952, when the J-65 engine and the F-84F airframe were finally assigned a high priority. The Americanization of the Sapphire also resulted in a weight increase that degraded performance and was never resolved. By January 1952, the YJ65-W-1 engine was considered obsolescent and required major modifications for further development, which again delayed production.

The first two production F-84Fs were delivered on December 3, 1952, a year behind schedule. In the face of all the development problems (which might have been resolved at the outset had there been a proper development program to begin with) the Air Force approved a revised schedule that allowed further delays at both the Republic and General Motors plants.

It turned out that the initial YJ-65 engine was not interchangeable with successive models, which meant that an airplane built for the YJ-6b-W-1 was required to use the engine, unless it underwent major airframe modification. While Wright replaced the obsolescent YJ-65-W-1 with the improved YJ-65-W-1A and developed the more powerful J-65 engine, Republic was producing three F-84F airframes per day and putting them in storage pending delivery of a satisfactory engine, each of which would require major modification to the airframes in order for the new engine to be used. In June 1953, while investigating the possibility of equipping the F-84F with a General Electric engine, the Air Force was forced to decide that the first 275 F-S4Fs would retain the YJ-65-W-1 engine. Except for these and some 100 other F-84Fs that were fitted with the YJ-65-W-1A, all F-84Fs were eventually equipped with the J-65-W-3 engine during one of the many modification programs.

As if the engine problems weren’t enough, major problems because of design deficiencies in the F-84F airframe and development of the subsystems created additional delay. By mid-1953, after more than a year of effort, the tail was still considered unacceptable for any kind of tactical operations, while both the longitudinal and lateral controls remained inadequate at high speeds. Redesign of the landing gear up-lock was necessary since the basic hydraulic system was over-sensitive; the electrical emergency system was still sensitive and prone to failure, while the dive brakes could be damaged by spent cartridges. Most importantly, none of the weight problems had been solved.

A year later, in mid-1954, correction of most of the design deficiencies was finalized, though unavoidable delays occurred when a stabilator was installed in production F-84F aircraft due to the long lead time required for manufacture of the stabilator. In order to continue production, the initial production F-84Fs were equipped with a two-piece "poor man's flying tail," consisting of an interconnected horizontal stabilizer and elevator. Although it had been successfully flight tested by Republic, this did not work operationally and in December 1954 the Air Force ordered installation be stopped and that those already installed be removed. By the end of 1954, many other expensive and time-consuming modifications had been made, or were scheduled. 785 F-84Fs had been modified with aileron spoilers at a cost of $4.7 million. 506 received true air speed indicators at a coast of $1.3 million. 258 were to be modified with the F-5 auto-pilot at an estimated cost of $3 million.

In January 1955, two and a half years after the end of the war the F-84F was supposed to fight, the Strategic Air Command’s 506th Strategic Fighter Wing finally received their first 14 F-84Fs. However, these aircraft were of no use past allowing initial pilot proficiency training because of their unsatisfactory engines and other deficiencies. By May 1954, SAC had 125 of the 400 F-84Fs which were powered by the obsolescent YJ-65-W-1 engines, or the still-deficient YJ-6S-W-1As. All 400 of these aircraft would eventually be used only for training until they could be remanufactured for foreign service with worthwhile engines; interestingly, it was two squadrons of these awful airplanes that would be the only F-84Fs to ever see combat, when flown by the French during the 1956 Suez War.

It wasn’t until May 12, 1954, that Tactical Air Command achieved Initial Operational Capability with J-65-equipped F-84Fs, while a few of them finally reached TAC's 405th Fighter Bomber Wing, which only had 36 of 72 aircraft that June when the first J-65-equipped F-84Fs joined the 27th Strategic Fighter Wing, six months later than originally scheduled.

Even then, deficiencies in the J-65-equipped F-84Fs accepted since May 1954 resulted in the Air Force grounding several of the aircraft and suspending deliveries from Republic. That August, Republic was directed to reduce its daily output from five to three aircraft - two F-84Fs and one RF-84F - and that September a hold order was placed on 400 of the last 500 F-84Fs scheduled for production. Simultaneously, the Air Force began a new series of operational suitability tests known as “Project Run In.” The tests, completed that November, "proved the F-84F a satisfactory fighter-bomber, capable of the mission role for which it had been planned" as well as a "considerably better aircraft than the [F-84]G." The conclusions of Project Run In, combined with a reorganization of the quality control group by Republic and an increase in trained production personnel resulted in approval by the Air Force of an accelerated delivery schedule that would see all the F-84Fs stored by Republic readied for delivery by March 1955. Unfortunately, this was not the end of the troubles, since TAC F-84F units began experiencing difficulty with the braking system, while engine failures in November and December 1954 resulted in the grounding of all F-84Fs in early 1955 and the stopping of further deliveries. The production hold order issued in September 1954 was rescinded in February 1955, after which F-84F deliveries resumed. A possible solution had been bandied about, to exchange the GM-built J-65 for the GE-built J-73, but was rejected in March. Soon after, SAC and TAC F-84Fs again experienced a number of engine flame outs when flying in heavy precipitation and several accidents occurred in severe weather as the result of engine failures that were caused by faulty compressor shrouds. While Republic worked to solve this, flying restrictions were again imposed. The program experienced another 6-month delay in 1956 due to a union strike at Republic.

Republic delivered the last Military Assistance Program F-84F in February 1957, ending production. GM had produced their last Thunderstreak two years earlier. 2,852 F-84Fs had been produced for MAP, and 1,496 for the Air Force, which was 756 fewer than originally ordered.

The F-84F did not linger long in first-line Air Force service. SAC transferred its first F-84Fs to the Air National Guard in August 1954, only 8 months after its first wing had accepted their first aircraft, and the last Thunderstreak left the Air Force inventory in January 1958 when the last TAC F-84F went to the Guard.

The Thunderstreak came close to going to war when four wings of ANG F-84Fs were called to active duty and deployed to Europe during the Berlin Crisis in 1961. Perhaps the most well-known mission of an ANG F-84F during this period was the one flown from Lakenheath, England to Chaumont AFB in France, during which the pilot was routed through a thunderstorm that taxed his flying ability to the limits and saw him nearly crash. The experience was memorialized by the pilot - Richard Bach - in his first book, “A Stranger To The Ground,” published two years later. The book has been compared with such classics of aviation writing as Antoine d’Saint-Exupery’s “Wind, Sand and Stars,” and this aviation writer recommends it to you as a book I have read with equal love five times in the past 30 years.

The call-up for the Berlin Crisis created a crisis for the operation of the F-84F by the Guard, as recall of the ANG units made spare parts critical, while the age of the aircraft imposed heavier maintenance requirements which led to all F-84Fs being grounded once again in March 1962 for the replacement of corroded control rods.

The use of the F-84F ended in Europe in 1964 when the F-104G began replacing the Thunderstreak in the Luftwaffe fighter-bomber units, while the French used theirs until the next year. The F-84F continued to serve with the air forces of Denmark, Italy, Belgium, the Netherlands, Greece, and Turkey into the 1970s.

Reviewing the history of the development and production of the F-84F, I am reminded of a few major motion pictures I was involved with that are rightly adjudged great failures, each of which would likely have been successful had the time been taken at the outset to develop the screenplay (the motion picture equivalent of a production development program), the point where making major changes is both cheap and easy. The same is true of airplanes and proves the truth of the old saying “why is there never enough time to do it right, but always time to do it over?”

| THE KIT |

Monogram first released their F-84F in 1983, two years after Heller released

kits of both the F-84F and the RF-84F. These kits have been available ever

since as they have been re-released. The Monogram kit is considered less

accurate in outline than the Heller kits, though it provides better detail,

particularly in the cockpit and gear wells. Both series of kits are examples of

the state of the art as of the late 1970s, with raised panel lines and some

overall fit issues.

Monogram first released their F-84F in 1983, two years after Heller released

kits of both the F-84F and the RF-84F. These kits have been available ever

since as they have been re-released. The Monogram kit is considered less

accurate in outline than the Heller kits, though it provides better detail,

particularly in the cockpit and gear wells. Both series of kits are examples of

the state of the art as of the late 1970s, with raised panel lines and some

overall fit issues.

This kit by Kinetic is not exactly “new,” since it is such a close fit to the

Monogram kit that an upper wing part from Monogram will fit the lower wing part

of the Kinetic kit, as will the fuselage halves from the two fit simila rly.

The Kinetic kit offers panel lines that are deep enough to be noticeably too

deep for a 1/48 kit, while the plastic surface is very slightly pebbly, just

sufficient to be very noticeable under a metal paint finish, though it would be

acceptable if one was doing either an Air National Guard airplane in ADC Grey or

a camouflaged airplane. Those who worry about these things say that the dive

brakes are more accurately placed on this kit than on the Monogram kit that

sired it. The clear plastic is acceptable, while the cockpit detail is much

softer than the earlier Monogram kit. The fuselage has been modified to allow a

gun bay with an open panel, similar to that found in the Tamiya F-84G, which

probably means there will be “fit issues” here if you want to close it up and

preserve the aircraft’s lines.

rly.

The Kinetic kit offers panel lines that are deep enough to be noticeably too

deep for a 1/48 kit, while the plastic surface is very slightly pebbly, just

sufficient to be very noticeable under a metal paint finish, though it would be

acceptable if one was doing either an Air National Guard airplane in ADC Grey or

a camouflaged airplane. Those who worry about these things say that the dive

brakes are more accurately placed on this kit than on the Monogram kit that

sired it. The clear plastic is acceptable, while the cockpit detail is much

softer than the earlier Monogram kit. The fuselage has been modified to allow a

gun bay with an open panel, similar to that found in the Tamiya F-84G, which

probably means there will be “fit issues” here if you want to close it up and

preserve the aircraft’s lines.

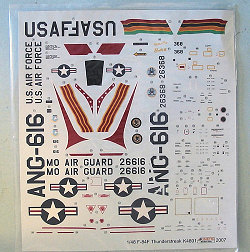

The kit decals provide markings for a natural metal F-84F of the Missouri Air Guard and an unidentified Air Force Thunderstreak. The MO-ANG airplane could be painted in ADC Grey and these markings used to do an airplane from the Berlin Crisis if one so desired. The sheet includes enough stencils to look “busy,” but there are less than half the stencils one finds in the Revell-Germany release of the old Monogram F-84F. (What Tom doesn't say, is that this sheet is an exact copy of an old Monogram sheet. Ed)

AMS

Resins F-84F cockpits:

AMS

Resins F-84F cockpits:

The detail of both this kit and the old Monogram kit can be vastly improved if one gets the resin set recently created by Harold Offield’s aptly-named AMS Resin, a small “garage kit” aftermarket producer. The sets - which come in versions specifically for both the Monogram and Kinetic kits and for USAF/ANG or European versions- includes a superbly-detailed cockpit tub, ejection seat and headrest, instrument panel, rudder pedals, gun sight, a new nose gear bay vastly superior to those provided by Kinetic or Monogram, and an exhaust tube better than either kit has. Harold has also just recently completed a rear fuselage part that provides the early Thunderjet-style ventral fin, which was used on the French F-84Fs that took part in the Suez Intervention. The set has an introductory price of $18.95, which is set to go to $24.95 to cover the cost of production. I highly recommend these sets for anyone who wants a really “definitive” F-84F in their collection. AMS Resin can be contacted at

| CONCLUSIONS |

I have to wonder why any company would do what is essentially an attempt at cleaning up and modernizing another company’s earlier product. I’ve personally never heard that many people say of the Monogram kit - which can be found at shows for half the price of this kit - that it’s “unbuildable” because of the misplaced air brakes or the raised panel lines, while the plastic is superior as a base surface for a natural metal paint scheme. I have built several of the Monogram kits, and never felt it was lacking in the final result. If you’re one of these people who thinks that an older kit with raised panel lines is “obsolete” and thus “unbuildable,” then this kit is for you. But I suggest you do it as an ANG bird in SEA camouflage, or a camouflaged European airplane, because it’s going to be hard to get a surface smooth enough to do a natural metal or overall aluminum lacquer scheme. I do hope Kinetic’s upcoming 1/32 F-86F is superior to this first try.

Review kit courtesy of Stevens International

June 2007

If you would like your product reviewed fairly and quickly by a site that has over 350,000 visitors a month, please contact me or see other details in the Note to Contributors.