|

KIT: |

AMT/ERTL 1/72

X/Y-B-35 Flying WIng |

|

KIT #: |

8615 |

|

PRICE: |

$Long OOP but

available |

|

DECALS: |

Two options |

|

REVIEWER: |

Lee Kolosna |

|

NOTES: |

|

Looking like something out of a science fiction

story, the Northrop B-35 and follow-on B-49 Flying Wing is a classic

example of a technological idea that was too far ahead of its time.

Proposed in 1941 by Northrop in response to an inquiry by the USAAF, the

futuristic bomber was given the green light for construction of a prototype

plus four smaller proof-of-concept aircraft. These test aircraft, dubbed

N9M, flew first to validate that the design of a flying wing was viable and

could deliver the perceived advantages of lower drag and higher lifting

capability than convention aircraft configurations. The flights of the N9M

were generally successful, although they were affected by the inevitable

teething problems of any new aircraft design. The fourth and last N9M

built still exists today at the Planes of Fame Museum in Chino, California

and flies occasionally.

The XB-35 emerged from the Northrop manufacturing

plant in Hawthorne, California and took to the air on June 25, 1946.

Powered by four Pratt & Whitney R-4360 Wasp Major engines which drove

contra-rotating four-bladed propellers in a pusher configuration, the XB-35

was instantly beset with problems with engine cooling and reliability of

the complex gear box arrangement. A second XB-35 was built and joined the

first at Muroc Army Air Field (later renamed Edwards Air Force Base for Air

Force pilot Capt. Glenn Edwards who died coincidentally enough while

testing the YB-49) for flight test. The third airframe, designated YB-35,

dispensed with the contra-rotating props in favor of a more conventional

design, but results were still disappointing as the range and top speed

were much less than originally predicted. Consequently, the design was

vastly modified to accommodate the newly emerging jet engine technology,

and the remaining YB-35s in the pipeline were built up as the all-jet

XB-49.

The XB-35 emerged from the Northrop manufacturing

plant in Hawthorne, California and took to the air on June 25, 1946.

Powered by four Pratt & Whitney R-4360 Wasp Major engines which drove

contra-rotating four-bladed propellers in a pusher configuration, the XB-35

was instantly beset with problems with engine cooling and reliability of

the complex gear box arrangement. A second XB-35 was built and joined the

first at Muroc Army Air Field (later renamed Edwards Air Force Base for Air

Force pilot Capt. Glenn Edwards who died coincidentally enough while

testing the YB-49) for flight test. The third airframe, designated YB-35,

dispensed with the contra-rotating props in favor of a more conventional

design, but results were still disappointing as the range and top speed

were much less than originally predicted. Consequently, the design was

vastly modified to accommodate the newly emerging jet engine technology,

and the remaining YB-35s in the pipeline were built up as the all-jet

XB-49.

As a combat weapon, the B-35/B-49 aircraft were not very good.

In addition to the disappointing results of flight-testing that revealed

shortcomings in range, payload, and top speed, the aircraft wasn't a

particularly stable bombing platform, which made for poor bombing

efficiency. After an extended test program and the realization that the

design wasn't living up to its promise, the Air Force abandoned the project

and scrapped all the airframes and the tooling. Much has been made by

conspiracy theorists about the underlying reasons for this vendetta by the

US government against Jack Northrop, but the simple facts were that the

flying wings weren't as capable as the B-36 and B-47 programs that they

competed against.

All was not lost, however, as four decades later came the

Northrop B-2 stealth bomber, a legacy to the original flying wing design.

With the help of computerized flight controls and modern manufacturing

technology, the flying wing is now a much more viable weapons system and

has entered the operational inventory of the US Air Force

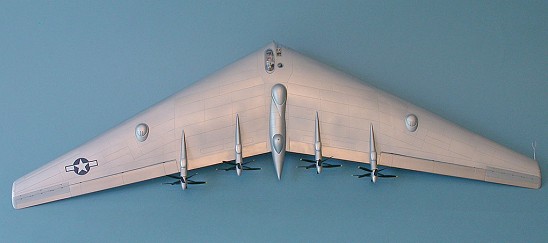

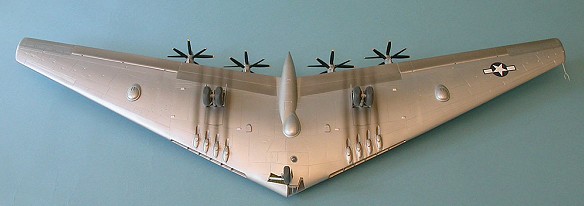

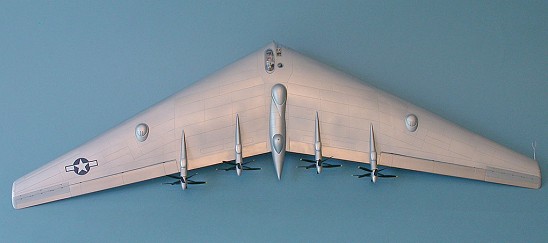

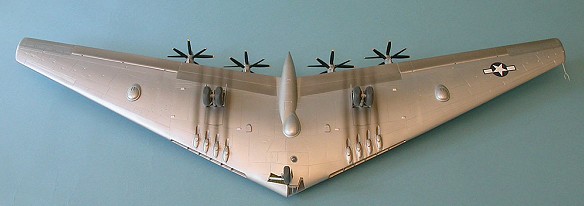

This kit, released in 1995, came very near to the

end of the line of AMT/ERTLís manufacture of aircraft model kits. It

was an audacious choice of subject and coincided with a release of a kit of

the jet-powered YB-49 flying wing. The modeler has the choice of

either making the first of the two XB-35s with contra-rotating propellers

or the sole YB-35 with conventional four-bladed props. The model is

molded in light g ray

plastic and comes in a huge sturdy box. The box is almost too big for

the contents. A fairly detailed interior is provided. There

arenít a large number of parts to assemble. The tires are flattened

on the bottom, a nice feature, and the clear parts are thin and

transparent. The instructions guide the modeler during assembly to

the slight differences between the XB-35 and YB-35, and decals are provided

for one example of each.

ray

plastic and comes in a huge sturdy box. The box is almost too big for

the contents. A fairly detailed interior is provided. There

arenít a large number of parts to assemble. The tires are flattened

on the bottom, a nice feature, and the clear parts are thin and

transparent. The instructions guide the modeler during assembly to

the slight differences between the XB-35 and YB-35, and decals are provided

for one example of each.

Since I built my kit in the XB-35 configuration, I

concentrated my research on that and found a few minor things missing.

There is a prominent pitot tube on the top of the wing near the co-pilotís

greenhouse that is not provided, as well as a couple of aerial posts

further back on the wing and on the inside starboard drive shaft nacelle.

One set of engraved panel lines doesn't line up as it crosses the joint

between the wingís center section and the outer wing panels. Initial

inspection of fit reveals that this model will require filler in rather

large quantities. Problem areas are the wing leading edge air intakes and

the fit of the outer wing panels. Since natural metal is the only accurate

finish for this aircraft, the modeler will have to exercise care in

insuring as smooth a surface as possible before applying their metallizer

of choice.

The instructions call for an all aluminum interior

(instead of the expected Interior Green), so I went along with that

recommendation and painted the interior pieces with Floquil Platinum Mist

enamel. The seat cushions are Insignia Red and the instrument panels are

flat black with white instruments. One thing I've learned about 1/72 scale

bomber kits is that I know that spending a lot of time detailing the

interior is not warranted, as one can't see much if anything once the

fuselage is together. The XB-35 is a slight exception as the pilotís and

gunnerís seats are very visible under the big bubble canopy, so you might

want to spend some time there by adding harnesses. Everything else is

pretty much hidden, though.

I glued the cockpit interior into the bottom of the

center portion of the wing and stuck an automobile tire wheel weight right

next to it to insure that the model sits forward on its tricycle landing

gear. If you don't add the weight, the model will be a tail-sitter, which

is kind of ironic because it really doesn't have much of a tail to begin

with.

I glued the cockpit interior into the bottom of the

center portion of the wing and stuck an automobile tire wheel weight right

next to it to insure that the model sits forward on its tricycle landing

gear. If you don't add the weight, the model will be a tail-sitter, which

is kind of ironic because it really doesn't have much of a tail to begin

with.

I glued all the major pieces together and got to

work on filling the large seams encountered with the leading edge air

intake pieces and the join of the outer wing panels. I filled everything

with thick CA glue and sanded and polished until I was satisfied with the

result. On the underside of the model, the air intake piece cuts right

across the four engine exhaust fairings, making for more of a challenge to

get a smooth and seamless appearance. I wasn't terribly successfully, but

fortunately that area is not really noticeable unless you pick the model up

and look underneath.

The propeller drive shaft nacelles were glued on

next. Fit is merely adequate, and I used putty at the transition between

the nacelle and the wing to fill in a gap there. I spent a lot of time

cleaning up all thirty-two propellers and the spinners to remove mold

marks.

I did a quick check of the fit of the

clear parts. The bubble canopy fits very well, as do the gunner

observation blisters. The large blister in the tail was faired over with

aluminum in the XB-35, but is clear in the YB-35. The co-pilotís window

and greenhouse comprise two pieces and don't fit well at all. They really

should be faired into the wing, but I didn't have the fortitude to mess

with it, since I had just recently spent dozens of hours doing the same

onerous task with a Monogram P-61. The fit of the transparency is merely

okay on the topside, but large gaps abound around the bottom piece. Again,

I figured that no one would be picking up the model to look at the

underside, so I let it slide.

I did a quick check of the fit of the

clear parts. The bubble canopy fits very well, as do the gunner

observation blisters. The large blister in the tail was faired over with

aluminum in the XB-35, but is clear in the YB-35. The co-pilotís window

and greenhouse comprise two pieces and don't fit well at all. They really

should be faired into the wing, but I didn't have the fortitude to mess

with it, since I had just recently spent dozens of hours doing the same

onerous task with a Monogram P-61. The fit of the transparency is merely

okay on the topside, but large gaps abound around the bottom piece. Again,

I figured that no one would be picking up the model to look at the

underside, so I let it slide.

Since the model was going to be finished in natural

metal, I carefully sanded and polished out each seam, them went on a

mission to find any stray scratches on the other portions of the model that

would stand out like a sore thumb under the metallic paint. Everything was

smoothed with a tri-grit sanding file, followed by Novus plastic polish #3

and #2. I restored the panel lines obliterated in the sanding process with

a scriber and a flexible ruler and washed the model in the kitchen sink

with some dishwashing soap and warm water before heading out to the paint

barn.

I primed the model with Floquil Old Silver enamel. This

allowed me to spot and correct any areas that I didn't get totally smooth

on the first go-round. After making the necessary repairs, I sprayed the

model with Alclad II Lacquer White Aluminum. After studying every photo of

the X and YB-35 that I could find, I determined that the rear portions of

the wings were made of a darker aluminum, with an even darker band of metal

around the ailerons. I masked the appropriate areas off and sprayed the

rear parts of the wings with Alclad Dark Aluminum, while the ailerons got a

s pray of Testors Metalizer Stainless Steel. I masked off a few more random

panels on the wings and used Alclad Duraluminum and Testors Metalizer

Aluminum Plate to add interest to the otherwise bland finish.

pray of Testors Metalizer Stainless Steel. I masked off a few more random

panels on the wings and used Alclad Duraluminum and Testors Metalizer

Aluminum Plate to add interest to the otherwise bland finish.

My kit decals had

yellowed, so I used aftermarket sheets from AeroMaster and Eagle Strike for

the national insignia and the serial numbers. Note that the XB-35ís wing

insignia are aligned in a non-standard manner for either 1940s aircraft

(perpendicular to the centerline) or 1950s aircraft (in line with the wing

centerpoint). I don't know why, but the photos are clear about this, so I

set my decals accordingly, canting them at about 10 degrees off from

perpendicular. After the decals dried, I sprayed a very light coat of

Future floor polish to blend everything together with a uniform sheen.

Photos show very prominent exhaust staining on all the piston-engined

flying wings, so I used Tamiya Smoke to replicate that. The landing gear

wells were painted with Polly Scale Interior Green. I added a black

acrylic wash to bring out the details. The landing gear and wheels were

painted with Floquil Platinum mist and the tires were painted with Polly

Scale RLM 66 and weathered lightly with Polly Scale Dust.

I masked the canopy

pieces with drafting tape and sprayed them with aluminum. The attachment

of the sprue to the main bubble canopy left a very noticeable mark that I

could not eliminate with sanding and polishing, so I took a little artistic

license and painted over that blemish as well. I don't think anyone will

ever notice.

Masking and painting the

yellow propeller tips, flat black blades, and aluminum spinners was time

consuming. The fit of the completed propeller assembly is not very

precise, either.

I glued the landing gear on and was pleased at how everything

aligned properly. The clear parts were attached with Micro Krystal Kleer.

I glued on the pitot tube and pushed in all the propeller assemblies to

complete the project in just 32 hours of effort, which is a very low total

for me.

I glued the landing gear on and was pleased at how everything

aligned properly. The clear parts were attached with Micro Krystal Kleer.

I glued on the pitot tube and pushed in all the propeller assemblies to

complete the project in just 32 hours of effort, which is a very low total

for me.

I know I'm going to sound like a broken record on this: this is

a model you never see built. It is funky looking to be sure,

and somewhat challenging to do well because of its fit issues and the

requirement for a natural metal finish on a relatively large model.

These kits aren't made anymore and I don't know when or if they will ever

be reissued. Fortunately, you can pick one up fairly easily on eBay

or at model swap events for not a lot of money. It builds up quickly

and you can definitely be assured that you will the first (and only) person

on your block with a model of this interesting airplane.

July 2005

Baugher, Joseph: Northrop B-35,

http://home.att.net/~jbaugher2/b35.html

If you would like your product reviewed fairly and quickly by a

site that has nearly 300,000 visitors a month, please

contact

me or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

I did a quick check of the fit of the

clear parts. The bubble canopy fits very well, as do the gunner

observation blisters. The large blister in the tail was faired over with

aluminum in the XB-35, but is clear in the YB-35. The co-pilotís window

and greenhouse comprise two pieces and don't fit well at all. They really

should be faired into the wing, but I didn't have the fortitude to mess

with it, since I had just recently spent dozens of hours doing the same

onerous task with a Monogram P-61. The fit of the transparency is merely

okay on the topside, but large gaps abound around the bottom piece. Again,

I figured that no one would be picking up the model to look at the

underside, so I let it slide.

I did a quick check of the fit of the

clear parts. The bubble canopy fits very well, as do the gunner

observation blisters. The large blister in the tail was faired over with

aluminum in the XB-35, but is clear in the YB-35. The co-pilotís window

and greenhouse comprise two pieces and don't fit well at all. They really

should be faired into the wing, but I didn't have the fortitude to mess

with it, since I had just recently spent dozens of hours doing the same

onerous task with a Monogram P-61. The fit of the transparency is merely

okay on the topside, but large gaps abound around the bottom piece. Again,

I figured that no one would be picking up the model to look at the

underside, so I let it slide. pray of Testors Metalizer Stainless Steel. I masked off a few more random

panels on the wings and used Alclad Duraluminum and Testors Metalizer

Aluminum Plate to add interest to the otherwise bland finish.

pray of Testors Metalizer Stainless Steel. I masked off a few more random

panels on the wings and used Alclad Duraluminum and Testors Metalizer

Aluminum Plate to add interest to the otherwise bland finish. I glued the landing gear on and was pleased at how everything

aligned properly. The clear parts were attached with Micro Krystal Kleer.

I glued on the pitot tube and pushed in all the propeller assemblies to

complete the project in just 32 hours of effort, which is a very low total

for me.

I glued the landing gear on and was pleased at how everything

aligned properly. The clear parts were attached with Micro Krystal Kleer.

I glued on the pitot tube and pushed in all the propeller assemblies to

complete the project in just 32 hours of effort, which is a very low total

for me.