Execuform 1/72 XP-87 Blackhawk

|

KIT #: |

? |

|

PRICE: |

Pretty sure it was under $10 at the

time. Ed |

|

DECALS: |

None |

|

REVIEWER: |

Carmel J. Attard |

|

NOTES: |

Bare bones vacuform kit with no external detail |

The XP-87 Blackhawk conceived in

response to USAF request for an all weather jet powered interceptor. Design

attempted to integrate radar, weapons, crew and aircraft into self contained,

ground vectored air defence weapon. It was the first pure jet aircraft and also

the last project made by Curtiss. Curtiss leader Walter Tydon designed this

radar equipped multi-jet night fighter. The type was powered by four engines

type Westinghouse J-34 WE7 each giving 2,795 lbs static thrust. It could attain

a maximum speed of 564 mph, a service ceiling of 45,000 ft and a range of 1,891

nautical miles with 3,100 gallons of fuel.

Development crippled due to early state of the art technical

inadequacies. This manifested that the interceptor had underpowered engines

overweight, dynamic flutter in empennage components, excessive take off run,

brake fade, and radar failures. Time, technology and politics were the cause for

this to be the last Curtiss design for the Air Force. The aircraft achieved 66

hours of flight time during 56 scheduled flight tests.

state of the art technical

inadequacies. This manifested that the interceptor had underpowered engines

overweight, dynamic flutter in empennage components, excessive take off run,

brake fade, and radar failures. Time, technology and politics were the cause for

this to be the last Curtiss design for the Air Force. The aircraft achieved 66

hours of flight time during 56 scheduled flight tests.

The main bulkheads at wing spars pass through, pressure cabin, empennage

and armament areas. Remaining sections joined by longeron and beltframes covered

with metal skins having flush access panels. The wing had dual main spars with

deep lip flanged machined skin panels inboard and tapered skins outboard.

All-metal aileron, speed brakes and wing flaps. Nacelle box shaped to house two

engines and main landing gear. The gear attaches from steeple frame from main

spars. Engine intake ducts divides

around wheel well. Tail cone divider is of stainless steel with removable

panels. Nose gear well is 9.5 inches offset to port of centre. The horizontal

tail has multiple spars with heavy tapered skins. Elevator is all metal and has

two mass balance configurations, which were used during the test program.

Vertical tail and dorsal had multiple closely spaced spars with heavy

skins. Rudder is all metal. Armament was not fitted on flight test aircraft.

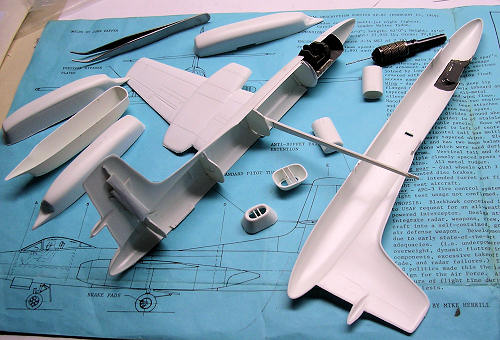

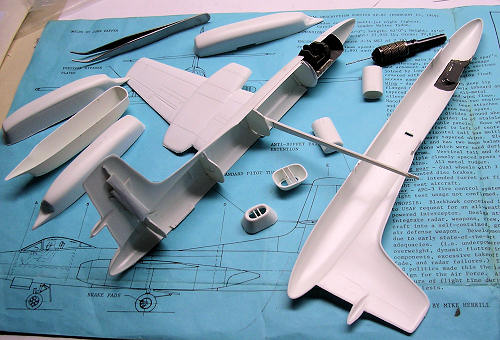

Kit is ‘bare bones’

not much detail at all. Every detail had to be scratch built, no interiors, no

landing gear oleo or wheel well detail or crew office interior at all. It

consists of two sheets of white styrene with vac-form parts to make all the

major components essential ly wing, tail planes and fuselage parts. Six bulkhead

sections are given on scale plans so that these can be made from backing

styrene. A canopy in clear acetate is also provided. There are two instruction

sheets. An A4 size sheet with building instructions and a double A4 size sheet

printed on blue paper which contains accurate 4-view 1/72 scale plans by Mike Herrill, which are excellent for reference purposes. A scrap view also shows the

position of the offset nose gear. 5 bulkhead sections are also depicted to

produce them from plastic sheet.

ly wing, tail planes and fuselage parts. Six bulkhead

sections are given on scale plans so that these can be made from backing

styrene. A canopy in clear acetate is also provided. There are two instruction

sheets. An A4 size sheet with building instructions and a double A4 size sheet

printed on blue paper which contains accurate 4-view 1/72 scale plans by Mike Herrill, which are excellent for reference purposes. A scrap view also shows the

position of the offset nose gear. 5 bulkhead sections are also depicted to

produce them from plastic sheet.

A quick observation

indicates that as with several of vac form models the vac parts have a slightly

blistered aspect at the surface which means that in order not to have part items

on the thick side there have to be scraping on the outer surface of parts before

one starts to draw and scribe the panel lines and other detail.

The round part

edges are scribed, and then broken away from the sheet. The edges are sanded

on a flat sanding paper until a crisp seam line joint is produced, extra

care for trailing edges. Having obtained the desired shape of parts,

reference is made to drawing and panel lines and/or or brakes on all wings

and part of fuselage sections are all drawn in pencil. With each part placed

flat on a surface, a steel ruler and sharp pointed blade are used to score

to a certain depth on the marked panel lines. No special tool is used but

these same lines are scored aga

The round part

edges are scribed, and then broken away from the sheet. The edges are sanded

on a flat sanding paper until a crisp seam line joint is produced, extra

care for trailing edges. Having obtained the desired shape of parts,

reference is made to drawing and panel lines and/or or brakes on all wings

and part of fuselage sections are all drawn in pencil. With each part placed

flat on a surface, a steel ruler and sharp pointed blade are used to score

to a certain depth on the marked panel lines. No special tool is used but

these same lines are scored aga in this time using the blunt end of an X-acto

blade so that the ridges formed are removed. Fine sanding removes any

residue left. I found this technique quite effective in the end.

in this time using the blunt end of an X-acto

blade so that the ridges formed are removed. Fine sanding removes any

residue left. I found this technique quite effective in the end.

Bulkheads are made for

the fuselage and nacelles. A floor is installed at the cockpit and detail to

suite added to interior which are in form of instrument panel and bulkhead, side

consoles, two ejection seat and control column, as well as equipment that one

could imagine after reference to photo particularly the space at aft of crew

seats. A compartment inside the nose is built to house the lead weight, while

box shaped plastic blocks are built and

fixed to the nose and engine nacelles to

form the wheel wells. A long wing spar is passed through cut square holes in the

fuselage halves.

fixed to the nose and engine nacelles to

form the wheel wells. A long wing spar is passed through cut square holes in the

fuselage halves.

With nacelle bulkheads

in place, the engine nacelle halves are dry fitted, and when desired correctness

is obtained the nacelle halves are fixed together. Each nacelle needed tail pipe

area opened up and two styrene tubes installed for exhaust tail pipes. The

nacelle nose cap required the addition of the intake duct. Halves. These ducts

had two vertical divider plates installed at a slight angle. When dry the

nacelle and nose cap are fitted to upper wing half, and the bottom wing half is

now fixed to the wi ng assembly. The wing spar is now positioned and bonded to

one side of the wing and nacelle parts so that the spar can slide through the

fuselage and provide extra strength. When the nacelle only are dry on one wing

half, the spar was slid through the fuselage and the opposite wing panels with

the vertical tail. When alignment is correct continued assembling the remaining

nacelle. For the tail planes a spar of aluminium tubing was installed through

the vertical fin. This aligned and bonded the two tail plane parts.

ng assembly. The wing spar is now positioned and bonded to

one side of the wing and nacelle parts so that the spar can slide through the

fuselage and provide extra strength. When the nacelle only are dry on one wing

half, the spar was slid through the fuselage and the opposite wing panels with

the vertical tail. When alignment is correct continued assembling the remaining

nacelle. For the tail planes a spar of aluminium tubing was installed through

the vertical fin. This aligned and bonded the two tail plane parts.

Attention was then

given to detailing the cockpit office, adding seats etc. Canopy was cut from

mold form and carefully trimmed to sit on fuselage contour. While adding the

little filler required care was taken not to fill the scribed detail panel

lines. The wheel well legs were made from metal tubing cut to small size and

joined to stretch sprue parts so that the scale plans were used for reference.

The wheels were slightly reduced in size while the nose wheels were replaced

with a set from spares box. These are smaller in diameter than the main wheels.

Wheel doors were detailed as best one could add detail to the inside face of

door parts. Scratch built segments formed brake pads that were added to main

wheel hubs.

Wheel wells were

zinc chromate but all door interiors were white. Cockpit interior is dark

grey while exhaust area being silver.

The rest of aircraft was overall high

gloss black, using Revell acrylic black, two coats with dry space in between

allowed. Other details as wheel legs and wheels were white and silver. I had

a decal sheet picked from spares box. Crew figure added to give scale

indication of the true size of the fighter aircraft. Window frames were made

from cut black decal strips and sealed in place with a coat of Klear.

The rest of aircraft was overall high

gloss black, using Revell acrylic black, two coats with dry space in between

allowed. Other details as wheel legs and wheels were white and silver. I had

a decal sheet picked from spares box. Crew figure added to give scale

indication of the true size of the fighter aircraft. Window frames were made

from cut black decal strips and sealed in place with a coat of Klear.

Like most of vac-form

kits this was fun to build and it also offered a challenge in a way as it

required a lot of additional parts, and more satisfying the result was. Thanks

to Scott Van Aken of

www.modelingmadness.com

who sent the kit for this

kit-build review. This also made me look deeper into what Execuform has on offer

in their vast range of kits. In due course more from this range will be

hopefully added to my future builds. In a few words, one tends to develop a

passion for vac form models and an obsession to build them.

Carmel J. Attard

June 2011If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

state of the art technical

inadequacies. This manifested that the interceptor had underpowered engines

overweight, dynamic flutter in empennage components, excessive take off run,

brake fade, and radar failures. Time, technology and politics were the cause for

this to be the last Curtiss design for the Air Force. The aircraft achieved 66

hours of flight time during 56 scheduled flight tests.

state of the art technical

inadequacies. This manifested that the interceptor had underpowered engines

overweight, dynamic flutter in empennage components, excessive take off run,

brake fade, and radar failures. Time, technology and politics were the cause for

this to be the last Curtiss design for the Air Force. The aircraft achieved 66

hours of flight time during 56 scheduled flight tests.

in this time using the blunt end of an X-acto

blade so that the ridges formed are removed. Fine sanding removes any

residue left. I found this technique quite effective in the end.

in this time using the blunt end of an X-acto

blade so that the ridges formed are removed. Fine sanding removes any

residue left. I found this technique quite effective in the end.  fixed to the nose and engine nacelles to

form the wheel wells. A long wing spar is passed through cut square holes in the

fuselage halves.

fixed to the nose and engine nacelles to

form the wheel wells. A long wing spar is passed through cut square holes in the

fuselage halves. ng assembly. The wing spar is now positioned and bonded to

one side of the wing and nacelle parts so that the spar can slide through the

fuselage and provide extra strength. When the nacelle only are dry on one wing

half, the spar was slid through the fuselage and the opposite wing panels with

the vertical tail. When alignment is correct continued assembling the remaining

nacelle. For the tail planes a spar of aluminium tubing was installed through

the vertical fin. This aligned and bonded the two tail plane parts.

ng assembly. The wing spar is now positioned and bonded to

one side of the wing and nacelle parts so that the spar can slide through the

fuselage and provide extra strength. When the nacelle only are dry on one wing

half, the spar was slid through the fuselage and the opposite wing panels with

the vertical tail. When alignment is correct continued assembling the remaining

nacelle. For the tail planes a spar of aluminium tubing was installed through

the vertical fin. This aligned and bonded the two tail plane parts.