Trumpeter 1/32 Allison V-1710

| KIT #: | 02228 |

| PRICE: | Came with a P-40 kit |

| DECALS: | |

| REVIEWER: | Spiros Pendedekas |

| NOTES: |

| HISTORY |

Allison, a Division of General Motors, began developing the ethylene glycol-cooled V-1710 in 1929, in order to meet a USAAC need for a modern 1,000 hp (750 kW) engine, in order to fit into a new generation of streamlined bombers and fighters. The Great Depression slowed development, and it was not until December 14, 1936, that the engine flew in the Consolidated XA-11A testbed, with all U.S. entrants in the new pursuit competition designed around it.

The V-1710 is a 60° V12 engine with a displacement of 1,710.6 cu in (28.032 L). It features a single overhead cam per bank of cylinders and four valves per cylinder. The engine design benefited from the General Motors philosophy of built-in production and installation versatility, embracing modular design for aviation power plants. It was constructed around a basic power section, from which different installation requirements could be met by fitting the appropriate accessories at the rear and an appropriate power output drive at the front. A key feature was its ability to turn the output shaft clockwise or counter-clockwise by a relatively simple assembly process.

The

P-38, P-40, P-51A and P-82E used the V-1710-F, featuring close-coupled

propeller reduction gears, whereas P-39, P-63, and XB-42 Mixmaster used the

V-1710-E, exchanging the integral reduction gear for an extension shaft,

driving a remotely located reduction gear and propeller.

The

P-38, P-40, P-51A and P-82E used the V-1710-F, featuring close-coupled

propeller reduction gears, whereas P-39, P-63, and XB-42 Mixmaster used the

V-1710-E, exchanging the integral reduction gear for an extension shaft,

driving a remotely located reduction gear and propeller.

The V-1710 did not have a "high-altitude" supercharger because this was the USAAC specification; however, it included the option of using a then newly developed turbo-supercharger if a higher altitude capability was desired, and such was the case with the XP-37(YP-37), P-38, and XP-39.

Allison slowly but continuously improved the engine during the war, not only incrementally increasing the output power from 1000 hp to as much as 2300 hp, but also increasing the installed lifetime from 300 hours to as much as 1,000 hours for the less-stressed power-plants, with minimal weight escalation, not to mention the reduction of unit cost from $25,000 down to $8,500!

Regarding the inevitable comparison between the V-1710 and the Rolls-Royce Merlin, what can be said for the Allison is that it made more power at less boost, with a longer time between overhauls, and with a parts-count that was nearly half that of the Merlin engine, which greatly facilitated mass production. There was also a high degree of commonality of parts throughout the series. The individual parts of the Allison series were produced to a high degree of standardization and reliability, using the best technology available at the time.

Despite the fact that early V-1710 was height-limited for combat operations at a maximum of about 15,000 feet (4,600 m), it was available in comparatively large numbers and proved to be robust and little affected by machine-gun fire. It became the mainstay of some Allied Air Forces in all but the European theater of war. It was a classic engine that was present when needed. In total, 69,305 V-1710s were built by Allison during the war, all in Indianapolis, Indiana.

The iconic engine's useful life continued after

the war, as thousands were available on the surplus market, with many drag

racers, land speed racers and tractor pullers adopting the powerful and

reliable V-1710. The warbird movement began to restore and return to the air

examples of the classic fighters of the war and many V-1710-powered pursuit

airplanes began to fly again with freshly overhauled engines. The

reliability, maintainability, and availability of the engine has led others

to use it to power flying examples of aircraft whose original engines are

unobtainable, including newly manufactured Yak-3s -9s and even Ilyushin

Il-2s!

| THE KIT |

This

engine model is part of the well-known Trumpeter 1/32 P-40B kit. It is a

complete engine model in itself, consisting of no less than 38 parts (not

counting another 24 parts for the exhausts), all superbly molded and flash

free.

This

engine model is part of the well-known Trumpeter 1/32 P-40B kit. It is a

complete engine model in itself, consisting of no less than 38 parts (not

counting another 24 parts for the exhausts), all superbly molded and flash

free.

The part of the P-40B

instructions regarding the engine build is comprehensive, with the construction

spread in 7 clear steps. Generic color callouts are given, whereas no component

names are imprinted (like: cylinder head, breather tube etc.), which would be

very welcome, since not all interested modelers might be fully aware of this

engine’s nomenclature.

Upon building the ”donor” P-40B with closed engine top cover, I only used the

engine exhausts at it (by figuring out an effective way of securing them into

their openings, without having to use the assembled engine as a support). I was

consequently left with a practically complete and detailed V-1710 “kit”, which

would be a pity to leave it unassembled. Building of the V-1710 was thus

decided!

| CONSTRUCTION |

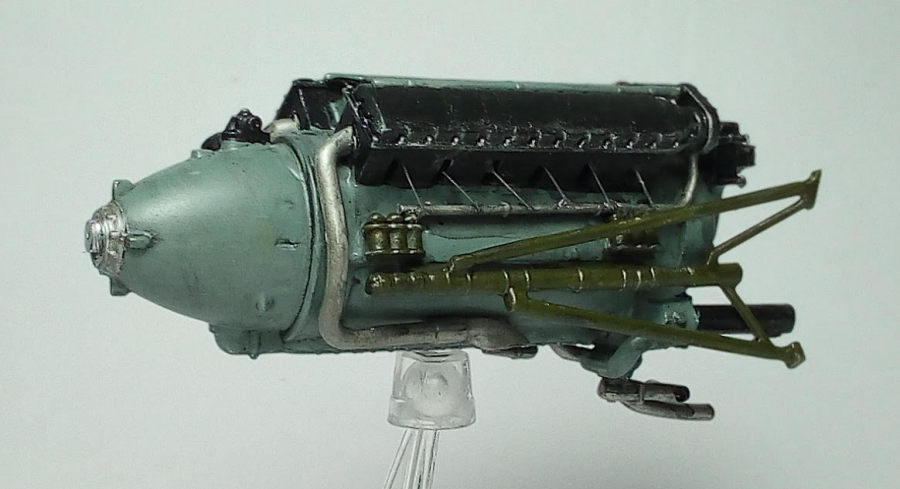

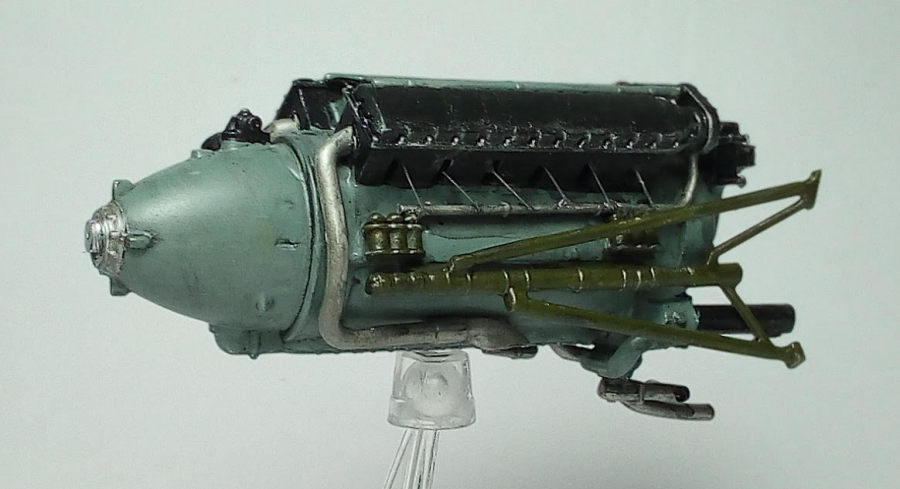

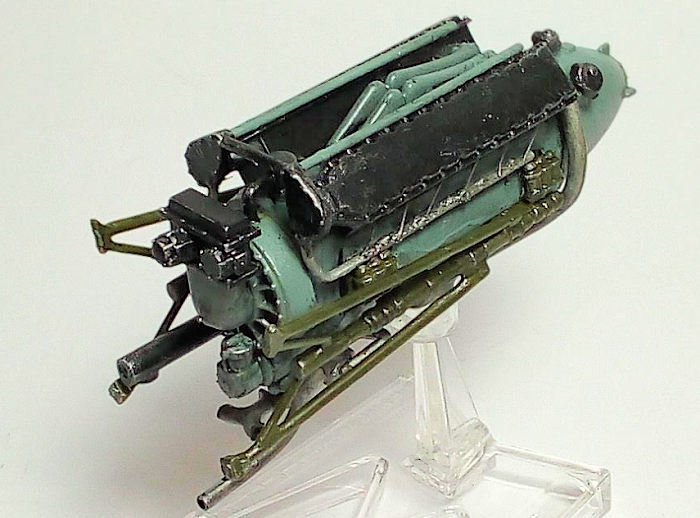

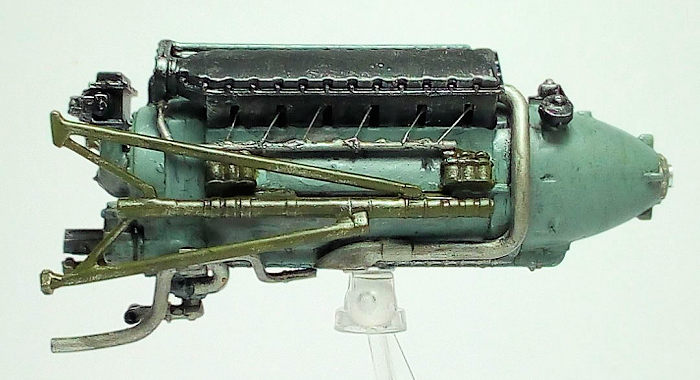

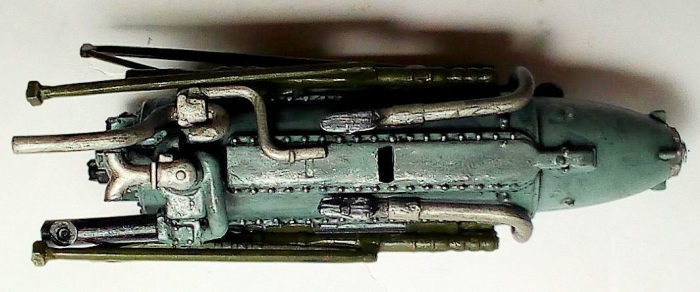

I started

by joining the two main block halves, then attached the two top cylinder heads.

The distinctive looking supercharger is an impressive subassembly, consisting of

no less than 12 pieces, with two major pieces comprising the main body and the

rest being various boxes or mechanical driven pumps that are attached onto it.

I started

by joining the two main block halves, then attached the two top cylinder heads.

The distinctive looking supercharger is an impressive subassembly, consisting of

no less than 12 pieces, with two major pieces comprising the main body and the

rest being various boxes or mechanical driven pumps that are attached onto it.

The distributor housing was attached on top of the supercharger, followed by the

two distributor rods that run along each cylinder head, with the engine hoisting

lugs between them and a breather on top of the crankcase. Finally, the driving

shaft housing was attached, followed by affixing a short rod of suitable

diameter, in order to represent the shaft.

With excellent allover fit and no filling/sanding required whatsoever, it was about time to visit the paint shop!

| COLORS & MARKINGS |

I was really lucky to find many net available color pics of accurately restored engines, providing invaluable info on individual parts painting. Thus, basic engine color, including supercharger body, distributor rods and hoisting lugs) was Hu87 Tank Gray (which actually dries to a lovely grayish blue, similar to the color observed at restored V-1710s), with black cylinder heads, distributor housing and more or less all pumps and added “boxes”. The driving shaft and its housing were painted chrome silver. All paintwork was done by hand, with a coat of Future sealing it upon drying.

| FINAL CONSTRUCTION |

The two cooling manifold inlets were bilaterally

attached after being painted steel, followed by 6 spark plug wires (represented

by thin pieces of stretched sprue) that were attached onto each of them, roughly

ending into (and nicely blanking) the recesses where the exhausts were supposed

to be attached.

In order to busy up the model, I decided to add the 4 mounting pads and the 2

engine supporting frames that are used for mounting the engine onto the

aircraft, all painted Hu226 (for the green zinc chromate).

The

various coolant/fuel/oil pipes, 7 in total, were painted steel and attached in

position. Since most of them were quite long, as they were supposed to be

attached to the corresponding plane position, I took an "artist's license'' and

reduced their length (yes, I brutally cut them…), to the point that they would

not protrude too much and ruin the engine homogeneous looks.

The

various coolant/fuel/oil pipes, 7 in total, were painted steel and attached in

position. Since most of them were quite long, as they were supposed to be

attached to the corresponding plane position, I took an "artist's license'' and

reduced their length (yes, I brutally cut them…), to the point that they would

not protrude too much and ruin the engine homogeneous looks.

After minor touch ups, I gave the whole engine a generous black wash, followed

by a not too subtle silver dry brushing: those two weathering techniques not

only effectively brought out quite a few details, but also gave the engine a

less toy-ish, more “operational” look. A final Satin coat sealed everything and

gave the engine its final finish.

I decided to mount the engine on a leftover Matchbox base (remnant of my brave

childhood years of putting together a Matchbox kit “in an afternoon”. I carved a

rectangular opening at the bottom of the engine and simply affixed it onto the

base.

I then called this engine model done!

| CONCLUSIONS |

An increasing number of aircraft kits provide

“complete” detailed engines, which, once assembled, painted and attached to the

plane, are viewable only through open panels. While a good number of modelers

opt for this arrangement, some others (yours truly positively included) prefer

to glue all panels closed, with the engine becoming invisible. Provided that an

efficient way to secure the exhausts (or nozzle or maybe the prop) onto the

plane can be found, the engine does not have to be installed, meaning that it

can be separately built and individually displayed.

Such was the case with this Allison engine of the “donor” P-40B kit, which was

just too detailed to find its way to the spares box! Apart from the addition of

spark plug wires that were made from stretched sprue, the model was built out of

the box (OOB) and was an very pleasant, non-time consuming process,

If you happen to have such leftover engine “kits”, you may consider putting

together some of them. Apart from being a possible nice break from “ordinary”

kit building, the completed models' different sight from the norm will

definitely draw some serious attention when proudly displayed in your showcase.

Happy modeling!

22 August 2023 Copyright ModelingMadness.com.

All rights reserved. No reproduction in part or in whole without express

permission. If you would like your product reviewed fairly and

fairly quickly, please

contact

the editor or see other details in the

Note to

Contributors.