Naval Models 1/350 HNLMS Friesland

|

KIT #: |

350-02 |

|

PRICE: |

@ 105 EUR |

|

DECALS: |

Yes |

|

REVIEWER: |

Frank Spahr |

|

NOTES: |

Naval Models PE set 350-02 RL

, Price @ 19 EUR.

Machined

brass barrels Master SM 350 053 (6 EUR), PE inclined ladders, Saemann

# 3065 (2.40 EUR for a set of 4 ), UNI caenis 20 den monofilament

rigging thread.

|

The eight vessels of the Friesland

class were commissioned by the Royal Netherlands Navy between 1956 and 1958.

This second postwar class of destroyers was roomier than the preceding Holland

class. Its armament was provided by Swedish manufacturer Bofors. For the

powerplant,

the systems used in

American Gearing class destroyers were built under licence. The ships

served throughout a big part of the cold war and received limited

upgrades only. The namesake Friesland was scrapped in 1979, the remaining

vessels were transferred to Peru in the early 1980s.

American Gearing class destroyers were built under licence. The ships

served throughout a big part of the cold war and received limited

upgrades only. The namesake Friesland was scrapped in 1979, the remaining

vessels were transferred to Peru in the early 1980s.

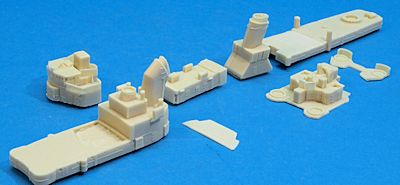

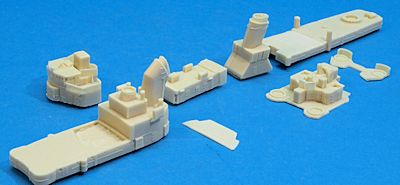

Dutch manufacturer Naval

Models offers a range of resin or multimedia

kits of mainly Dutch vessels. This kit is one of their earlier offerings.

It comes with a dedicated PE fret, wire and decals. The complementing additional

PE fret further details the model and provides alternative parts for some of

those included in the kit. The resin is reasonably well cast, yet not

exceptional, with more casting blemishes and larger casting plugs to be removed

than usual with the best products on the market. The kit instructions are very

well thought out and actually represent a building sequence that makes sense,

instead of the rather theoretic sequences you will often find, especially with

injection-moulded kits.

I started with cleaning up the resin

parts, doing some repairs with putty and drilling the (fortunately round) bridge

windows deeper.

I started with cleaning up the resin

parts, doing some repairs with putty and drilling the (fortunately round) bridge

windows deeper.

In building a waterline

model, the one-piece hull will either have to be laboriously reduced or the

full-hull model be embedded in a waterline block. I prefer doing the latter, so

I made a cutout in a fitting piece of foam board, sanded it to accept the hull

as good as I could, which left varying gaps. After insulating the hull with

vaseline, I applied white acrylic caulking from the hardware supermarket to the

base and fit the hull into the cutout, sculpting the acrylic caulking in the

process as desired. After two days curing time, I was able to remove the hull

and clean it up with lighter fluid prior to further work. The base was further

sanded and sculpted, and then painted in my usual method using white wall paint

for the desired surface structure and then various shades of

acrylic model

paints. All that fully cured, the base received several coats of a high gloss

solvent-based clear coat, followed by some drybrushing with white artistīs oil

paint. It was then set aside for the final process of mating ship and base.

acrylic model

paints. All that fully cured, the base received several coats of a high gloss

solvent-based clear coat, followed by some drybrushing with white artistīs oil

paint. It was then set aside for the final process of mating ship and base.

Returning to the ship, I continued

identifying subassemblies, cleaning parts up, assembling them and painting them.

On the whole, this model was built straight out of the box, save a few

exceptions. Firstly, I much prefer machined brass barrels to resin items, they

simply better look the part to me. Sadly, the rather peculiar 120 mm Bofors gun

barrels are unavailable as brass items. So I spent quite some while looking up

photos of the original guns and sifting through the aftermarket offerings to

find something that matched to a reasonable

extent. Finally I settled for

Masterīs 140 mm barrels for the IJN cruiser Nagara. Each barrel received a piece

of .2 mm brass wire to what I assume this was a coolant pipe

in the original gun. For the 40 mm AA guns, I only found barrels for the

earlier model from WW 2. After some filling with CA glue and the addition of a

small piece of styrene stock, they looked enough alike to feel I could get away

with it.

extent. Finally I settled for

Masterīs 140 mm barrels for the IJN cruiser Nagara. Each barrel received a piece

of .2 mm brass wire to what I assume this was a coolant pipe

in the original gun. For the 40 mm AA guns, I only found barrels for the

earlier model from WW 2. After some filling with CA glue and the addition of a

small piece of styrene stock, they looked enough alike to feel I could get away

with it.

Further additions

concerned the shipīs boats. I added leftover PE oars from my PE folder. I have a

normal A4 folder in which I collect the remains of any used PE sheet in clear

plastic binders, to store them safely and to easily find out what I can use for

a new project. In this case, I found some leftover PE combos of keel / propeller

/ rudder which fit nicely under the motor boats. I also replaced the PE

handrails atop the two windlasses by more delicate Saemann PE items. Saemann

also provided PE inclined ladders which were more detailed and delicate

than the kit PE items.

Most of the parts fit

quite well, and - as I already mentioned - the instructions were helpful and

user - friendly. The most tricky items were the complex inclined ladders aft the

bridge, especially how to bend them correctly. The PE gratings / walkways around

the aft funnel did not fit as I would have liked them to, and needed some

tweaking. The PE deflectors for the ASW rocket launchers were easily shaped

after some annealing. The parts are sturdy enough to withstand the heat, so this

was the easiest method for me.

The railing provided by

Naval Models was easy to work with and sufficient for my needs.

The model was primed with

solvent-based primer from the rattle can and then sprayed with appropriate

acrylic shades of, um, grey. A number of shades in the single digits did

suffice, though.

The model was given only limited

weathering, as reference images had showed well-maintained vessels throughout.

I ran into trouble decaling, though.

The stern hull number folded and tore irreparably, so I was forced to rename my

model from D 812 Friesland to D 814 Limburg - luckily the decal sheet includes

markings for all eight vessels of the class. Despite the name, the project was

completed on time and within the projected budget

(look here).

I did not use the decals for the warning circles around the gunhouses. Instead,

I engraved circles and used white paint in the engraved lines.

I ran into trouble decaling, though.

The stern hull number folded and tore irreparably, so I was forced to rename my

model from D 812 Friesland to D 814 Limburg - luckily the decal sheet includes

markings for all eight vessels of the class. Despite the name, the project was

completed on time and within the projected budget

(look here).

I did not use the decals for the warning circles around the gunhouses. Instead,

I engraved circles and used white paint in the engraved lines.

Limburgīs crew was

provided by the excellent 3D printed NorthStar sailors.

The model was rigged using

the trusty UNI Caenis 20 den monofilament line. Sadly, the tension was enough to

deform the rather flimsy topmasts and yards, so I had to try my hand at

correcting something Iīd rather not touch more than once. A Dutch flag was

painted on cigarette paper and glued to the flagstaff with clear acrylic gel.

After a final flat coat to

hide as much embarrassment as possible, the model was placed into the cutout

prepared in the base. It fit well. Any remaining small gaps were closed with

clear gloss acrylic gel. The model was glued to the base using caulking

silicone.

The

Friesland destroyers were the epitome of WW2 destroyer development, with

perfected radars and ASW equipment, but just before the momentous change the

advent of guided missiles would bring to warship design. Building this resin kit

had its challenges, but should be no problem for experienced modelers. The

resulting model depicts a ship with beautiful lines and a welcome example of a

vessel developed by one of the smaller navies during the cold war.

The

Friesland destroyers were the epitome of WW2 destroyer development, with

perfected radars and ASW equipment, but just before the momentous change the

advent of guided missiles would bring to warship design. Building this resin kit

had its challenges, but should be no problem for experienced modelers. The

resulting model depicts a ship with beautiful lines and a welcome example of a

vessel developed by one of the smaller navies during the cold war.

Frank Spahr

March 2015 If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

I started with cleaning up the resin

parts, doing some repairs with putty and drilling the (fortunately round) bridge

windows deeper.

I started with cleaning up the resin

parts, doing some repairs with putty and drilling the (fortunately round) bridge

windows deeper.  acrylic model

paints. All that fully cured, the base received several coats of a high gloss

solvent-based clear coat, followed by some drybrushing with white artistīs oil

paint. It was then set aside for the final process of mating ship and base.

acrylic model

paints. All that fully cured, the base received several coats of a high gloss

solvent-based clear coat, followed by some drybrushing with white artistīs oil

paint. It was then set aside for the final process of mating ship and base. extent. Finally I settled for

Masterīs 140 mm barrels for the IJN cruiser Nagara. Each barrel received a piece

of .2 mm brass wire to what I assume this was a coolant pipe

in the original gun. For the 40 mm AA guns, I only found barrels for the

earlier model from WW 2. After some filling with CA glue and the addition of a

small piece of styrene stock, they looked enough alike to feel I could get away

with it.

extent. Finally I settled for

Masterīs 140 mm barrels for the IJN cruiser Nagara. Each barrel received a piece

of .2 mm brass wire to what I assume this was a coolant pipe

in the original gun. For the 40 mm AA guns, I only found barrels for the

earlier model from WW 2. After some filling with CA glue and the addition of a

small piece of styrene stock, they looked enough alike to feel I could get away

with it. I ran into trouble decaling, though.

The stern hull number folded and tore irreparably, so I was forced to rename my

model from D 812 Friesland to D 814 Limburg - luckily the decal sheet includes

markings for all eight vessels of the class. Despite the name, the project was

completed on time and within the projected budget

(look here).

I did not use the decals for the warning circles around the gunhouses. Instead,

I engraved circles and used white paint in the engraved lines.

I ran into trouble decaling, though.

The stern hull number folded and tore irreparably, so I was forced to rename my

model from D 812 Friesland to D 814 Limburg - luckily the decal sheet includes

markings for all eight vessels of the class. Despite the name, the project was

completed on time and within the projected budget

(look here).

I did not use the decals for the warning circles around the gunhouses. Instead,

I engraved circles and used white paint in the engraved lines.