Paper Shipwrights 1/250 #10 Mortar Barge

| KIT #: | ? |

| PRICE: |

Free download |

| DECALS: | None - Prepainted |

| REVIEWER: | George Oh |

| NOTES: |

Card model |

| HISTORY |

platforms, the Federal navy employed mortars on barges that

were anchored close in-shore from their target/s so they could lob bombs over

fortification walls. Naturally,

they attracted some return fire and so required protection for the gun-crews.

This is a model

of the Federal Navy Mortar barge No. 10 that was anchored in the

| THE KIT |

While seeking a

model (of the HMVS Cerberus – but that is another story) by trolling the

Internet, I discovered the Paper Shipwright website, operated by David Hathaway.

David sells sheets of paper with parts printed (in colour) on them that

can be cut-out with scissors or a knife, and assembled onto a model using paper

glue. Some parts are to be

folded-over to create a thicker, more-robust part, while others are to be rolled

to form tubes (aka masts, gun barrels etc).

But this was a free download, so I grabbed a copy.

I started this kit because this is the sort of modelling I did when I was

a boy, it looked like an easy build of an unusual subject.

While seeking a

model (of the HMVS Cerberus – but that is another story) by trolling the

Internet, I discovered the Paper Shipwright website, operated by David Hathaway.

David sells sheets of paper with parts printed (in colour) on them that

can be cut-out with scissors or a knife, and assembled onto a model using paper

glue. Some parts are to be

folded-over to create a thicker, more-robust part, while others are to be rolled

to form tubes (aka masts, gun barrels etc).

But this was a free download, so I grabbed a copy.

I started this kit because this is the sort of modelling I did when I was

a boy, it looked like an easy build of an unusual subject.

| CONSTRUCTION |

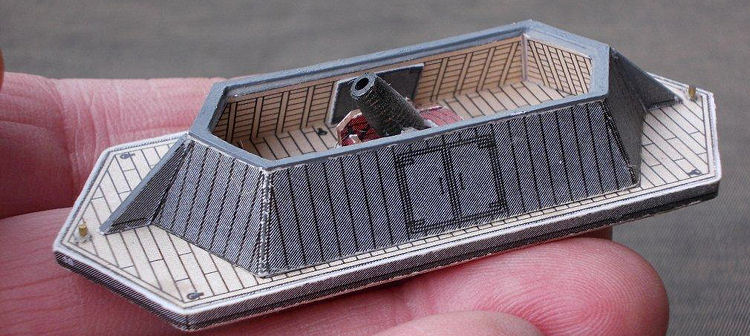

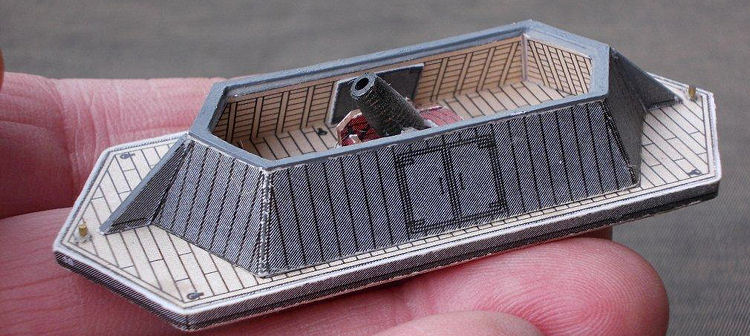

The waterlined

model consisted of a hull/deck/platform supported by an internal spine-and-ribs

structure surrounded by a narrow strip - the free-board.

On top of this went a round dais that mounted the short-barrelled mortar,

and the weapon was surrounded by a thick open-topped 6-sided superstructure.

I failed in the

construction of the hull because of the fragility of the ribs and spine, and

because they lacked tabs to attach to the underside of the deck.

So I replaced it with a plate of balsa-wood that was stiffened with a

brass rod (to stop it warping). But

I did use the surrounding narrow strip and deck piece.

The walls of the superstructure were thickened by sandwiching a piece of

cardboard between the kit parts, which made bending the angles difficult.

This was solved by sanding and dry-fitting.

OK – I had to paint the tops of the wall where the cardboard showed

through.

I also

thickened the dais and the small parts for the gun cradle, using thinner

cardboard. The parts were

manageable, but the parts for the trunions and barrel were even smaller.

I found it neigh impossible to roll them into tubes, let alone to join

them. Quickly, I surrendered and

turned one from a length of thick styrene chucked into my power-drill.

OK – I had to paint this. By

drilling a hole through the barrel, I was able to replace the trunions with a

piece of rod – not that I wanted the mortar to be capable of elevating or

anything.

And that was

it. There was no masking or

decaling, and only a little self-inflicted painting was required.

| CONCLUSIONS |

This is a great

little model – cost was nothing and it was only a little challenging.

It was a little difficult because of the small size and complexity of

some of the parts that I chose to replace.

For those 350-scale fanatics, or 700-scale phreaks, you can always

photo-reduce the original sheet (good luck with the building).

But it is unusual, and I’m happy to recommend it, and others of David’s

products (especially his lighthouses).

This is a great

little model – cost was nothing and it was only a little challenging.

It was a little difficult because of the small size and complexity of

some of the parts that I chose to replace.

For those 350-scale fanatics, or 700-scale phreaks, you can always

photo-reduce the original sheet (good luck with the building).

But it is unusual, and I’m happy to recommend it, and others of David’s

products (especially his lighthouses).

| REFERENCES |

October 2012

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.