Academy 1/35 M1A2 'Tusk II'

| KIT #: | 13298 |

| PRICE: | $35.00 |

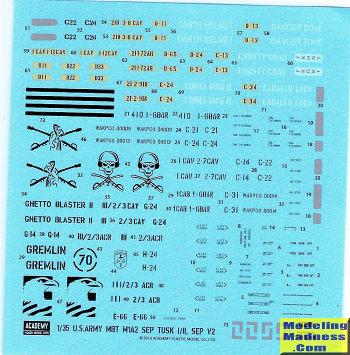

| DECALS: | Nine options |

| REVIEWER: | Donald Zhou |

| NOTES: | Advantages:Extremely detailed, single piece tracks, nine versions included. Disadvantages: Single piece tracks, instructions can be confusing. |

| HISTORY |

The M1 series of tanks was developed in the 70’s as a replacement for the venerable M60. Previously, in a joint program with then West Germany, the U.S. produced the MBT-70 in the ‘60’s as a replacement. That never worked. The then new 155mm short barreled cannon, which can fire the Shillelagh missile was prone to break down and jamming. The rest of the vehicle didn’t fare better either and both nations eventually backed out. The Germans went on to produce their own very successful Leopard II MBT while the U.S. went on to eventually produce the M1.

The first prototype was produced in 1976. The winner was Chrysler. The Germans, who were adamant on selling the Leopard to the U.S. was deemed too expensive while the GM design was deemed too inferior. The tank was the XM1. After Chrysler was bought out by General Dynamics, the design was further improved. It had the same 105mm Royal Ordnance cannon found on the M60, which is upgradable to the 120mm Rhinemetal smoothbore found on the Leopard II. It also had massive improvement to the armor with the British Chobham ceramic armor plates that’s a whole generation ahead of the rolled homogeneous armor found in the M60. The biggest improvement however, was the fire control system. Previous tanks all used analogue sights with daylight vision systems. The M1 replaced them with digital fire control computers with laser range finders that was several jumps ahead along with a Forward Looking Inferred sensors that allowed the tank to fight at night or bad weather. Efficiency were greatly improved although older more experienced crews’ improvement was only incremental. However, the improvements among new raw crews was three or even four times better than older tanks, meaning they can be brought up to standard far quicker. The tank entered service in 1980 and quickly started to prove themselves. Over 3300 M1 were produced. The tanks can run up to 45MPH although there are reports of crews who disabled their governors on the tanks and went up to 55MPH and even beyond! The tank also features an AGT-1500 turbine engine. The engine is quiet, so quiet in fact, the tank gained a nickname of whispering death and can use any sort of fuel, everything from diesel, to straight gasoline and in a pinch, raw alcohol can be burned (although as might surmised, using raw alcohol will wreck the engine’s life). In service, the tank just uses diesel to save logistics nightmares. However, the big disadvantage is the turbine is a huge fuel hog and draws as much as a gallon of fuel for every mile and its infer-red signature is also quite high.

The next major upgrades is the M1A1 version. The biggest difference is the main armament. The Rhinemetal 120mm smoothbore replaced the British 105mm rifled cannon. This meant ammo capacity was dropped from 53 to 42. The other was the armor. Especially the HA (Heavy Armor) and HC (Heavy armor Common) variants, which contained a layer of depleted Uranium to further harden and upgrade the armor. Other improvements includes better bustle racks and a hole was opened just in front of the loader. This hole will prove critical for the next series of upgrade then in development. Over 6000 M1A1’s were produced, many of them are now or have been upgraded under the AIM or Abrams Improvement Management program.

The tank, now named Abrams after late Gen. Creighton Abrams, baptism of fire came in the Middle East. When Iraq and Sadadum Insane invaded Kuwait, U.S. and her allies quickly formed a line of defense to defend Saudi Arabia. Critical among the pieces were Abrams. In fact, over 1800 of the tanks were sent to the Gulf, many of them the latest HA variants to deal with the T-72’s. Before the battle, questions about the tank’s price and effectiveness abound but all of that was settled quickly when the tank proved itself in battle.

In fact, the Abrams totally outclassed its opponents. It can hit its targets as far away as 2KM away and its rangefinders and FLIR worked well in both daylight and night, especially when smoke fire engulfed the region. In fact, one anecdote from the war shows just how near invulnerable the tank was. During a drive, one Abram got stuck in mud. The rest of the unit passed it by since they were under orders to keep moving. While waiting for a tow, three Iraqi T-72’s attacked. The first one fired a HEAT shell and did nothing to the tank. The M1 responded by firing an armor piercing shell that nearly blew the turret off! The second one, not heeding the lesson, also fired a HEAT shell that only made the tank angrier. A second round turned this tank into a funeral pyre. The third tank, finally heeding the warning, fired an armor piercing round that left a grove in the Abrams frontal glacis plate but did not penetrate. Seeing further fighting was redundant, it hid behind a sand berm, thinking it was safe. However, through its FLIR unit, the Abram tracked the last Iraqi tank and saw the heat plume from its exhaust and put the round where the turret was. The armor piercing round slammed through the sand berm and still penetrated the tank on the other side.

By this time, further Abrams had arrived but still no tow truck…Orders came from above to destroy the stricken tank in place. Since the rest of the Abrams crews did not have high explosives, they decided to use their main cannons for the job.

However, two rounds against the front armor proved to be useless, a tank came up against the side and fired one through the ammo storage bin and finally penetrated. All that did was to set off the blast off panel on top of the turret, which vent the explosive force upwards. After the fire died down, the tank proved to be as tough as ever! While discussing on what to do, the tow finally arrived and with three M88 recovery vehicles, the stricken M1 was finally dragged out of the mud!

There were some hard lessons too though. The least of which, like the M2 Bradley, it turned out, the biggest enemy wasn’t the enemy…it was friendly fire. Of the 9 Abrams destroyed in the war, 7 was from friendlies. At least two was from an errand AH-64 Apache strike with one total loss

After the war, further improvements were added. The biggest was the M1A2 version. The hole on top of the tank was replaced by a CIV or Commander Independent thermal Viewer. This allowed the tank to finally conduct “Search while hunt” at the same time. Electronics were further improved to allow one A2 to talk to another or any similarly equipped tank. Furthermore, to guard against the painful lesson of friendly fire, “cold” identification panels were added to the front of the turret, the side and rear. The A2 was also improved with the SEP or System Expansion Program and the SEP2, which added FBCB2 and other improvement to the armor etc.

By the time the second Gulf War rolled around, the Abrams that participated in this war only look like the same Abrams that participated in the first one. The insides though, were completely different and generations ahead. After the war, however, the Abrams faced its toughest test yet, fighting in urban terrain.

The fact of the matter is, tanks are not suited in urban terrain. They are too big, too unwieldy in a city and there are a lot of spots for insurgents to take pot shots at it. The press were quick to point out the Russian disaster that was Chechnya and Grozny. Insurgents quickly found out going toe to toe with an Abrams was tantamount to suicide. However, taking pot shot at it from the rear or firing an RPG from the rooftop at the tank’s roof is a far better option. Either that, or load up an IED and then blow up its soft underbelly!

To combat this, the Tank Urban Survival Kit (TUSK) upgrade was developed. This is a field upgradable kit that radically improve the tank’s survival in an urban terrain. The first thing added was something from WW II, an infantry to tank talkie phone on the back. The next one was a “V” shaped armor piece that was added to the belly to not only add armor strength against IED’s, but also to blunt and deflect the blast away from the tank. The third is a series of armor glass panes were added to both the commander and the loader’s weapon stations so they can operate their weapons out of the tank without worrying about snipers. Finally, to guard against the tank’s sides, a series of ERA armor panels were added to the tank’s side skirts.

When introduced, the kit quickly proved popular and well suited in an urban terrain. However, further improvements were added from combat reports. These became the TUSK II kit. These includes: further slate armors were added to the rear engine grill. A second .50 cal machine gun was added to the top of the main cannon and a series of ceramic tile ERA armor pieces were added to the turret sides and onto the existing side skirt ERA armor.

With these improvements, the tank soon proved to be a hard nut to crack. There is a M1A3 version. However, due to budget cuts, that version is in limbo so the Army and Marines will have to do with the current version for the foreseeable future.

| THE KIT |

Boy

are we living in the age of the Abram models! When Tamiya first came out with

their TUSK I so long ago, modelers were clamoring for something more accurate

since the hull was still based on their ancient M1 version that’s more like the

prototype M1. Warp a few years later, we now have a TUSK from Meng, Dragon,

Tamiya, RyeField, and Academy! So which is w

Boy

are we living in the age of the Abram models! When Tamiya first came out with

their TUSK I so long ago, modelers were clamoring for something more accurate

since the hull was still based on their ancient M1 version that’s more like the

prototype M1. Warp a few years later, we now have a TUSK from Meng, Dragon,

Tamiya, RyeField, and Academy! So which is w hich,

and what is what? It can get confusing. Let me just put it this way, if you got

money to spend, get either the Dragon, Meng or Ryefield kit. They are more

accurate and contains far more parts. But if you are on a tight budget, get the

Academy kit! It’s only $35 and except for a very few accuracy discrepancies,

more than fills your need if you want a TUSK! In fact, I would say, yes, the

competitors are more accurate but $10-$20 more accurate?!? Not really,

especially since you can build this tank either as an A2 SEP II, TUSK I, or TUSK

II version! So if you want the best bang for your bucks, this is the best kit to

go!

hich,

and what is what? It can get confusing. Let me just put it this way, if you got

money to spend, get either the Dragon, Meng or Ryefield kit. They are more

accurate and contains far more parts. But if you are on a tight budget, get the

Academy kit! It’s only $35 and except for a very few accuracy discrepancies,

more than fills your need if you want a TUSK! In fact, I would say, yes, the

competitors are more accurate but $10-$20 more accurate?!? Not really,

especially since you can build this tank either as an A2 SEP II, TUSK I, or TUSK

II version! So if you want the best bang for your bucks, this is the best kit to

go!

The first thing to do is to read instructions carefully. The instructions are broken down into 4 booklets with the fourth being nothing but the A2 version so if you are not building that version, you can discard it. However, constructions for all three are all over the first three and sometimes, it’s not made very clear so mark off the version you want to build since there are some hole drilling if you are building either the TUSK I and TUSK II versions.

The first booklet covers mostly the running gears and like any tank, there are a lot of them. Strangely, the bottom hull are in five pieces. The sides are separate and strengthened with two centrally mounted mounting pieces. Be sure to drill out the holes for the TUSK’s bottom armor piece.

After you finish with all the running gears, time to assemble the rear engine grill. Careful not to lose the small pieces to the carpet monster.

The second page deals with adding the top of the hull to the bottom and then the tracks. They are vinyl and to keep them together, Academy kept two track pieces as plastics and you can add them, top to bottom, to keep the tracks together. The tracks are absolutely the weakest part of the model. Yes, they are better than the half melted ones found on some of the earlier kits but still, the pins and the guide teeth are devoid of details and a few guide teeth are too small in size. Then the next few steps all deals with the side armor. This is easy if you are building the A2 version but quite bit more involved if you are building either the TUSK I or II. Be sure to drill out the correct holes. The hull is generally done at this point. Keep the side armor separate for ease of painting.

The turret construction starts with the main cannon. I have to congratulate Academy here on some smart thinking. Due to latest improvement in slide mold technology, something circular with hole in them can be made, like a barrel. And in this case, the main cannon barrel is one solid circular piece. The smoke discharger and the rear end piece attach to the main barrel from the rear and then is sealed off. Although still not quite as detailed as a metal barrel, it’s good enough for everyone who does not suffer AMS and is far better than trying to assemble the barrel in two pieces and then curing the seam that end result. There is a slight mold line that runs down the middle of the barrel. But a simple swipe of 600 grit sandpaper cured that easily enough.

The rest of the turret are assembled. The front glacis plate “cold” identification panels are in photo etch, so are the bustle racks bottom so break out the super glue. Before the turret top goes on the bottom, once again, make sure you drill out the correct holes for the TUSK versions.

The final assemblies

are all the machine guns that festoon the turret. The TUSK version is far more

co mplex

since bullet proof screens surround both the commander and loader weapon

stations with an extra .50 cal on the main cannon. If you are building the A2

SEP II version, a very nice CROWS II remotely operated weapon system is also

included. Again, just make sure you mark off which is which.

mplex

since bullet proof screens surround both the commander and loader weapon

stations with an extra .50 cal on the main cannon. If you are building the A2

SEP II version, a very nice CROWS II remotely operated weapon system is also

included. Again, just make sure you mark off which is which.

The kit is finished off with some extra stowage, including some jerry cans (both water and fuel), spare track links and some spare wheels. With way things go on an operational tank, you might want to get some extras from Tamiya, Meng or other third-party since I never ever saw an American armored vehicle that isn’t festooned to the teeth with various stowage, M1 included! The back end of these things are usually filled to the brim with coke boxes, water bottles, coolers, personal gears, tents, cots, blankets and MRE’s. 9 different vehicles markings are included so you might want to consult your sources or just whiff it!

| CONCLUSIONS |

Well, that’s about all. Again, if you got money to spend, get the Meng, Ryefield, or Dragon version of this tank since they are far more detailed. But if you want to save a few bucks and get your best bang, then this version more than fill the job! After only three days (on and off), I already finished most of it and got the first layer of paint on it! It’s that quick simply because nearly all of the pieces falls together and everything fit. The few seams are all my fault than the kit. Otherwise, if you want an M1A2 TUSK or just want another Abrams on the shelf, I highly recommend this kit. It’s majorly vice free and anyone who has a few kits under their belt should be able to make a wonderful armored vehicle. The only hitch for some are the vinyl tracks. They are not nearly as detailed as say, Dragon’s magic tracks. Then again, the reason I broke for this kit is because of the single piece vinyl. I’m tired of spending three or four nights putting all the guide teeth onto those pesky tracks no matter how detailed they might be in the end!!!!! This is why my Dragon M1A2 SEP is still in its box! So the choice is up to you!

March 2017

Copyright ModelingMadness.Com.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.

Back to the Main Page Back to the Review Index Page Back to the Previews Index Page