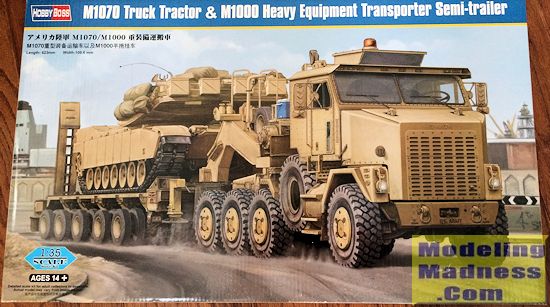

Hobby Boss 1/35 M1070 & M1000 HETS

| KIT #: | 85502 |

| PRICE: | $180.00 MSRP |

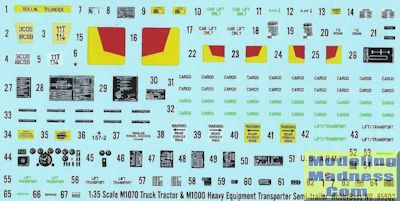

| DECALS: | Two options |

| REVIEWER: | Donald Zhou |

| NOTES: |

Advantage: huge full scale kit of this important vehicle. Contains both the tractor and trailer. Detailed throughout. Disadvantages: Many small parts. Complicated assemblies with multiple multimedia parts. Some mistakes in the instructions. |

| HISTORY |

After the war, despite the fact the Dragon Wagon was

upgraded to carry a heavier load, the weight outgrowth of the “Patton” series

MBT’s (M47, M48, and M60) soon put the Dragon Wagon to pasture. What was needed

was a bigger and heavier vehicle to do the job. That was the M911, a 6x6 vehicle

and trailer system that can haul up to 60 tons. The system was designated “Heavy

Equipment Transporter System”, or HETS. Designed specifically for the Patton

tanks, especially the M60, this vehicle gave many years of good services and is

still in use today in some countries to haul other heavy equipments other than

tanks.

However, during the 80’s, with the introduction of the

M1 Abrams series MBT, the M911 was starting to show its age, especially with the

weight creep of the new tank. When the M1-A1 HA (Heavy Armor) crept up to 70

tons, the M911 proved to have a hard time with it. During the Gulf War, it can

haul away the Abrams, but just barely at very slow speed and without any off

road performance. This resulted in a new requirement for a new HETS.

The fact of the matter is, this requirement was issued

even before Desert Storm. Several companies responded. The eventual winners were

Oshkosh, a heavy equipment producer in Wisconsin, who produces the 8x8 all-wheel

drive tractor, designated as the M1070 and System Electronics of St. Louis, who

produce a 40 wheeled trailer designated as the M1000. Together, they formed the

new HETS. The M1070 + M1000 HETS first entered service in 1993.

The new vehicle specifically fills the new

requirements, up and including able to haul away a 70 ton load (the weight of a

fully loaded M1-A2 Abrams) with off-road ability and minimum turning radius. The

last part made the vehicle a little complicated. The tractor is air ride capable

with the first and last set of axels able to turn. In order to keep the turning

radius to a minimum, the trailer, with 10 wheel arms, 5 on each side, with 4

wheels to each arm, are all hydraulically suspended. This not only provide each

with independent suspension, but also features a computerized weight

distribution system that automatically distribute the weight of a heavy object

evenly on the trailer. The computer also controls the arm’s movement so each of

the arm can be individually or turned together with the tractor to cut down the

turning radius. All the wheels, including the tractor’s features an independent

centrally controlled inflation system. Despite all these complexities, it only

take two crew members to operate although there is room in the cab for six in

order to comfortably seat the four crew members of an Abrams. Top speed is 45

MPH. The vehicle is highway capable, although due to its unusual large size, it

needs a permit to do so and usually only move on highway at night.

The new vehicle entered service in 1993 and slowly

replaced the M911 in the tank transporter role. It proved to be quite adept at

it. During Iraq and Afghanistan, rumors were flying around more than one crew

loaded their HETS with 100 tons of cargo. The vehicle certainly could handle it

albeit with the sacrifice of it’s off road ability and speed. At any rate, any

well trained HETS crew will tell you that the biggest thing to remember about

the vehicle is even with only “70” tons, you have to constantly control your

speed to “pull” your load and never ever let the load “push” you. If that

happens, especially downhill, then good luck stopping cause the only thing BIG

enough, and it have to be BBBIIIIGGG is all too sudden and all too horrifying to

think about! This is why I suspect the real speed of a HETS is much faster than

the quoted 45 MPH…..Although I do suspect with a full load or worse…..If the

vehicle goes faster than 45, than good luck trying to stop it! Currently, there

are 2600 vehicles in service with the U.S. Army, although some of the older

vehicles, whose life span are almost up are being dumped onto the civilian

market. The British also ordered a heavily modified vehicle, the M1070F to

replace the Scammel Commander to haul their Challenger II MBT and other

countries also uses it. In 2013, the new version, the M1070A1 entered service

with a 700 HP Caterpillar C18 engine (200 more than the old one) and an

automatic single speed transfer case is also provided so the crew does not have

to stop to change speed when dealing with a different grade.

| THE KIT |

This

is another one of those kit that I bought in China so many moons ago and got

left there when I returned back to the States. Now, four years later, I finally

got it back so here it is!

This

is another one of those kit that I bought in China so many moons ago and got

left there when I returned back to the States. Now, four years later, I finally

got it back so here it is!

Ohh boy that’s another big box with over 1000 parts

too! Yeah, once again, I got taken into “WTFBBQSAUCE HAD I GOTTEN MYSELF INTO”

land…….again! Maybe it’s because since I got it in China, and Trumpyboss (read,

Wasan Plastic Co.) again is a Chinese company, this means no tariffs, no

distribution fees (or very little) and overseas shipping costs, I got it for the

equivalent of only 85 bucks! Considering the fact the kit goes around $130

minimum these days, that’s a hell of deal so I snatched it up real quick

and…….Sigh………..”WTFBBQSAUCE HAD I GOTTEN….”!!!!!

Once you opened the box, you’ll at the same time giddy

with joy and curse yourself because once again….”WTFBBQSAUCE….” On one side, you

got all the parts for the tractor (Sprues A through K. Guess the Engine “Bonnet”

(sure clue that the translator is British trained) is sprue I). Sprue L through

R (Once again, guess the flatbed top is sprue O) are for the trailer. The middle

is the typical green small box that contains the wires for the winch, tires for

both the tractor and trailer, the single piece engine cab “bonnet” , photo etch

parts and the clear parts. All of the pieces are well molded and in good

clarity.

The minute you start reading the instruction book

(again book, not even close to being a booklet), you will start once again, with

the “WTFBBQ…..” Hey, are we going into a scheme here? You can bet you know what!

This because the complexity just takes your breath away! To tell you in detail,

let’s start in the beginning!

The

complexity starts with the details. I should know cause I already started on

this kit. The first two steps, which deals with the main tractor frame contains

98 parts alone! That’s more parts than even some 1/48th

scale jets! As you can imagine, after the two main frames comes together, put a

heavy book or something on top to keep the frame straight and level is a must

(leave off part A6 to help you with this). This two steps took a better part of

5 days to do, not just because of work, kids, keeping SWMBO waxed and happy and

to keep the frame straight and level, but also there are many small parts and

all sorts of subassemblies that you must be careful and assemble first before

everything comes together. Keep this in mind cause it will be another running

scheme throughout the kit! Also, already on the first step, a part number is

missing. If I remember correctly, part D13, the bottom bumper holder is drawn on

the instruction, but not numbered….So you must look for it on your own.

Steps 3 through 7 deals with all four axels on the

tractor and the main drive train and linkages. There are a lot. Again, pay

attention to the instructions….Wish they can put some words like “WATCH OUT!!!

Notice orientation!” (But then again, I can understand it. This because

especially if you go to places like Europe or Canada, where the French and

French Canadians are adamant on protection their own language, you can’t sell

the kit if it’s just printed in English alone…Then there are the Germans,

Spanish etc etc etc etc….Where will it end?) on some of the parts cause this is

important here. The way the parts are made, you can easily mess up on the

orientations of the axels assemblies, for ex. the main axel housing, the oil

sump hole should be pointed downward. But since the guidance plugs and holes are

made the same, you can easily mess this up and get a great axel assembly with

the hole on top. Not pointed towards the bottom! So study the instructions

carefully here! Another part were you can get the orientation wrong would be the

air bladders. The tractor again, is air ride capable and the air bladders are in

vinyl. Study the diagrams again until you are sure of how it goes before

committing it to superglue!

Steps

8 through 9 complete the mess of linkages and shock absorbers….Now you are

finally done with the frame details and already, I reckon over 300 parts are

gone…That’s more parts than some 1/35th

scale tanks!

Steps

10 through 15 deals with all the details on the side and front of the tractor

including the two big fuel drums, engine grills, and front fenders with details

such as lights, turn signals and light protectors. Now, notice now you are

starting to deal with a lot of photo etch. Be prepared, cause it’s about to get

worse. In fact, this kit contains a lot more photo-etch than even the 1/16th

King Tiger I previewed earlier. It’s obvious why cause this kit demands it.

Step 16 to 22 deals with the crew cab and as you can

expect, its one hell of an assembly! The only thing missing though, are the seat

belts...Guess the manufacturer thought since no Chinese ever put on their seat

belts, so must the Americans….Ohh well. Detailed interior sets are available now

from various third-party manufactures or you can scratch your own. Just to warn

you, the entire cab top is in photo-etch! So get that lighter and etch bending

tool ready! After you are done! Do not. Repeat! DO NOT put the cab onto the

frame! Skip all the way to step 30, where the instruction have you turn the

thing upside down and put in the last few underside parts. As you can imagine,

you do not want to do that with a big cab with some very delicate parts

straddling the frame! On top of that, as can be imagined, the whole entire thing

is quite heavy at this point!

Next, step 23 to 28 deals with the complicate winch

assembly. This one is a dozy and, well, is a kit onto its own. I reckon over

half of the parts are photo etch or in string. Now the string, if you have the

means, I recommend replacing it with copper or metal wires since Trumpeter’s

string flays the instant it touches paint! Take your time here since there are a

lot of metal parts.

Finally, step 29 to 32 deals with the last bit of

details. The mud guards are all in metal so you got your work cut out for!

So now, we start on the M1000 trailer with step 1

again. Through step 4, the “goose neck” is assembled. Again, leave off the tire

winch and spare tires, not unless you want to break them later when you have to

turn the trailer upside down again and again. I’ll deal with that later.

It’s at this point, you will deal with a lot and I

mean A LOT of plastic tubeings since as I’ve stated earlier, the trailer is

hydraulically suspended and the kit give the full details on these. Again, the

steps are in metal so be patient with all these.

Step 5 to 9 covers the trailer bed details. There are

a lot of small parts so don’t try to feed the carpet monster too much. Luckily,

this kit seems to provide a few extra small parts so you have some leeway.

Step 10 15 deals with the truck wheel arms and

hydraulic line assemblies. As you can imagine, studying the assembly diagrams

again and again as these things are a mess of complications of wires and

attachment points. Step 14 will have you attach the goose neck. As much as you

want to delay this, you can’t. Not only are there are some major tubings that

joins the neck with the trailer, some of the bottom parts can not be placed in

until the tubings are in place since they will block the access points if you

put them in early before the neck is attached.

Steps 16

through 21 deals with some of the trailer details such as the warning lights,

loading ramps and chalk blockers. Once again, be prepared to bend a lot of

photo-etch here.

Steps 16

through 21 deals with some of the trailer details such as the warning lights,

loading ramps and chalk blockers. Once again, be prepared to bend a lot of

photo-etch here.

Finally the last two steps, Steps 22 and 23, deals

with attaching the trailer to the tractor and attaching the blue and red

hydraulic and electrical lines and the black air hose! Recommending buying some

thin copper wire and insert it into the tubing to make them bend easier. It’s

only after you are finished with all of these steps and swallowed up close to

1500 parts are you finally done. Ohh, that’s not including at least 200 photo

etch, what looks like a mile worth of vinyl tubing., 9 tractor tires (8 on the

truck, 1 spare), and finally, 42 trailer tires (40 on the trailer, 2 spares)!

| CONCLUSIONS |

Umm yeah…

This is another one of the Trumpeter/Hobbyboss kit

were the instant you open the box, it gut punches you to the floor. When you get

back up to take another look, it promptly drop kick you back where you belong,

all the while while you are muttering, “WTFBBQSAUCE HAD I GOTTEN MYSELF INTO!!!”

As I’ve said, I already started and two weeks, I still

have not completed the bottom of the frame yet….And this is not even getting

into all the major photo-etch assembly! Currently, there are plenty of

aftermarket makers who are making resin wheels (for those that hate vinyl. But

just be warned, it takes as much as $80 get all of them, for both the tractor

and trailer and the spares!), detailed interior sets and a detailed resin

engine. I say, “why bother?” yes, there is no engine, even though the “bonnet”

moves, yes, there are no seat belts and yes, the interior can be made to look

much better but again, when enough is enough? And what comes out is more than

enough for most people and you can indeed make a showpiece winner straight OOB!

Recommended for experienced modelers with at least

some experiences in annealing and bending photo-etch parts. Not for beginners or

the faint of heart!

July 2015

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.