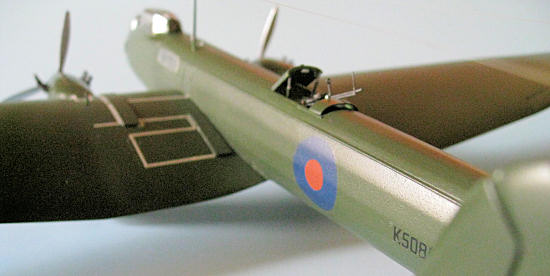

Contrail 1/72 Fairey Hendon

| KIT #: | ? |

| PRICE: | $2.00 in 1980 |

| DECALS: | One option |

| REVIEWER: | Tom Draper |

| NOTES: | Vacuformed plastic. Modeldecals used for roundels |

| HISTORY |

The Fairey Hendon was a

failed British attempt to design a modern heavy night bomber.

The project started in 1927 and was delayed by the crash of the

prototype. The Air Ministry delayed

things even more while it tried to decide whether to convert Faireyís stringer

and fabric design to an all-metal aircraft.

In the event, only 14 service examples were manufactured starting in

1936, by which time the aircraft was obsolescent.

All went to 38 squadron.

Itís two 600 HP Kestrel engines provided a stately cruise of 130 mph with a bomb

load of 1660 lbs. Mercifully,

Hendons were taken out of service in 1939 to be replaced with Whitleys.

The Fairey Hendon was a

failed British attempt to design a modern heavy night bomber.

The project started in 1927 and was delayed by the crash of the

prototype. The Air Ministry delayed

things even more while it tried to decide whether to convert Faireyís stringer

and fabric design to an all-metal aircraft.

In the event, only 14 service examples were manufactured starting in

1936, by which time the aircraft was obsolescent.

All went to 38 squadron.

Itís two 600 HP Kestrel engines provided a stately cruise of 130 mph with a bomb

load of 1660 lbs. Mercifully,

Hendons were taken out of service in 1939 to be replaced with Whitleys.

| THE KIT |

Actually, it took me longer

to build my example than it took the RAF to get their 14 aircraft.

I got out my Putnam, converted the dimensions to 1/72 scale, blew up

their plan to size, and concluded the kit was hopelessly incorrect.

That was that for about twenty-five years until I got it out again.

I really like the lines of the Hendon (itís roughly the size of a B-17

and quite graceful) and

spent a day researching the aircraft, this time, on the

Internet. I found out that

Putnamís info on the Hendonís dimensions was incorrect, and so was their

drawing. Basic dimensions were

miscalculated. My plan from

Aviation News was correct, but I thought it was wrong because I believed

Putnamís dimension info.

However, after much investigation, I discovered that the kit itself was

correct as to fuselage and wing dimensions.

Things seemed ready to go and I was in business.

Unfortunately, Contrailís plan that came with the kit and the kit itself

was based on the incorrect plan in Putnamís when it came to wing underside shape

and tail dimensions. The prototype

kept getting confused with the production aircraft, the tail of which differed

from the prototype in shape as well as vertical and horizontal measurements.

The kit had the tail shape right, but scaled them to the prototypeís

dimensions.

spent a day researching the aircraft, this time, on the

Internet. I found out that

Putnamís info on the Hendonís dimensions was incorrect, and so was their

drawing. Basic dimensions were

miscalculated. My plan from

Aviation News was correct, but I thought it was wrong because I believed

Putnamís dimension info.

However, after much investigation, I discovered that the kit itself was

correct as to fuselage and wing dimensions.

Things seemed ready to go and I was in business.

Unfortunately, Contrailís plan that came with the kit and the kit itself

was based on the incorrect plan in Putnamís when it came to wing underside shape

and tail dimensions. The prototype

kept getting confused with the production aircraft, the tail of which differed

from the prototype in shape as well as vertical and horizontal measurements.

The kit had the tail shape right, but scaled them to the prototypeís

dimensions.

After researching the plane,

and comparing the kit to the photos and info I amassed, here is what I was faced

with:

∑

The fuselage was correct in length,

although lumpy, with simplified detail.

The clear part for the nose turret area was useless.

The one-man greenhouse was correct for the first few production aircraft.

∑

The tail dimensions were for

the prototype, not for the production aircraft.

All the parts were too narrow and too short, which I discovered after I

had spent many hours following the Contrail drawing, unwittingly making them for

the prototype.

∑

The decal sheet lettering

was correct for the first production aircraft in 1938, early in its service

career, (white underwing serials were changed to black about 1937, as was the

walk way markings) but the roundels were incorrect in size and missing two wing

roundels to boot. The decals also

included six tiny ďKeep Clear of PropellorsĒ warnings that go on the engine

nacelles and wing leading edge.

∑

The decal sheet lettering

was correct for the first production aircraft in 1938, early in its service

career, (white underwing serials were changed to black about 1937, as was the

walk way markings) but the roundels were incorrect in size and missing two wing

roundels to boot. The decals also

included six tiny ďKeep Clear of PropellorsĒ warnings that go on the engine

nacelles and wing leading edge.

∑

The wing was correct in

dimensions, but in the middle of the build, I found that the curve of the bottom

of the wing was incorrect, necessitating cutting away most of the bottom surface

and replacing it with flat plastic card.

∑

The white metal Ramís Horn

exhausts were correct for the prototype, but not for K5085, which was different

from most of the production run.

∑

The wheel spats were ľĒ too

short. No main landing gear was

provided.

∑

There was only rudimentary

interior detail Ė and I could find no visual references at all for the specific

interior configuration.

Therefore, I had to design

and scratch build almost all external and internal detail using plastic card,

wire, and a few parts from a Matchbox Supermarine Stranraer, all added at

various stages during the build.

| CONSTRUCTION |

The Wing:

It came in five pieces, capturing the washout of the wingtips and the

gulled center section. I sanded off

all detail, cut off the ailerons, and scribed the complex pattern of bomb cell

doors on the center section.

Later, when mating the wing with the fuselage, nothing looked right.

I found a great photo of K5085 flying overhead.

It exposed all kinds of detail, but proved what I

feared was true.

The curve of the bottom of the wing was grossly incorrect.

I cut out the entire bottom of the wing surface except for the leading

and trailing edges and replaced it with flat card stock.

Of course, I had to rescribe all the bomb doors again.

I added internal structure, including a coffee stirring stick for

rigidity, in order to mate the new bottom surfaces with the remaining wing.

This procedure went quite smoothly and allowed the wing and the bottom of

the fuselage to agree with each other Ė and the photo.

The trailing edge was thinned and the ailerons were shaped to scale and

modified to accept the control horns, which were added later.

feared was true.

The curve of the bottom of the wing was grossly incorrect.

I cut out the entire bottom of the wing surface except for the leading

and trailing edges and replaced it with flat card stock.

Of course, I had to rescribe all the bomb doors again.

I added internal structure, including a coffee stirring stick for

rigidity, in order to mate the new bottom surfaces with the remaining wing.

This procedure went quite smoothly and allowed the wing and the bottom of

the fuselage to agree with each other Ė and the photo.

The trailing edge was thinned and the ailerons were shaped to scale and

modified to accept the control horns, which were added later.

The Fuselage:

I found a jar that matched the curves in the fabric scalloping, and

sanded and filled until the lumpiness was gone along the fuselage stringers.

Since the aircraft was used as a troop carrier as well as a night bomber,

I added a catwalk down the interior, curving around the offset pilot station all

the way to the tail gunnerís compartment.

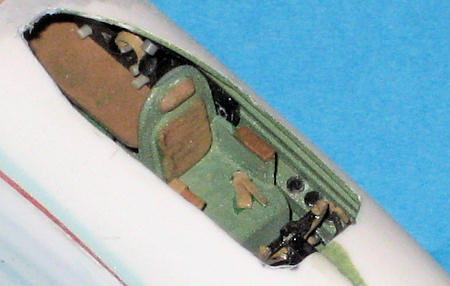

I scratch built a cockpit and a navigatorís station below and behind,

plus a dorsal gun position, and a nose and a tail gunnerís station.

I went into the propeller spare parts box and retrieved a 1/48th

Lindberg He.111 prop spinner, that I modified into a mold (using clear vinyl)

for a vacuformed nose turret, which I made with my Mattel Vac-U-Form machine I

bought in 1965. (One of the most useful modeling tools ever created sez I).

Guns came from a Supermarine Stranraer kit, as did a number of parts that

I used here and there.

The Fuselage:

I found a jar that matched the curves in the fabric scalloping, and

sanded and filled until the lumpiness was gone along the fuselage stringers.

Since the aircraft was used as a troop carrier as well as a night bomber,

I added a catwalk down the interior, curving around the offset pilot station all

the way to the tail gunnerís compartment.

I scratch built a cockpit and a navigatorís station below and behind,

plus a dorsal gun position, and a nose and a tail gunnerís station.

I went into the propeller spare parts box and retrieved a 1/48th

Lindberg He.111 prop spinner, that I modified into a mold (using clear vinyl)

for a vacuformed nose turret, which I made with my Mattel Vac-U-Form machine I

bought in 1965. (One of the most useful modeling tools ever created sez I).

Guns came from a Supermarine Stranraer kit, as did a number of parts that

I used here and there.

I made the unique and very

cool windblast shields that protected the dorsal and tail gunners, plus a

sliding hatch with the Vac-U-Form and a piece of basswood, sanded and sealed

smooth with Aerogloss model airplane dope.

The cockpit canopy came from the kit, which sits offset to port, adding

extra interest to the model.

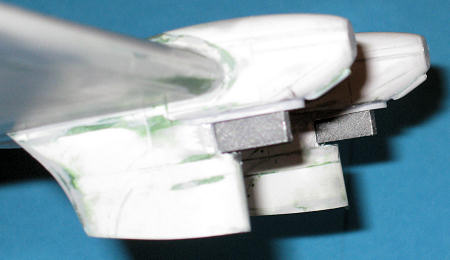

The Engine Nacelles:

Comprised of two times two pieces, the nacelles included the wheel pants,

as well as crudely depicted radiator shells.

I had started these assemblies before I discovered the wing problem, so

they were cut out to conform to the incorrect curved wing undersides.

This, of course, made for mucho rework, but that paled before the fact

that the pants were ľĒ too short.

Therefore, I had to cut the bottom portion off and add a horizontal plug halfway

up the pant. This caused all kinds

of problems with the curve of the pantsí trailing edge, but it did give me a way

to mount the kitís wheels by cutting off a portion of tire and gluing the rest

inside the pants. They also removed

the need for scratch building landing gear, except for the parts nearest the

wheels.

The Engine Nacelles:

Comprised of two times two pieces, the nacelles included the wheel pants,

as well as crudely depicted radiator shells.

I had started these assemblies before I discovered the wing problem, so

they were cut out to conform to the incorrect curved wing undersides.

This, of course, made for mucho rework, but that paled before the fact

that the pants were ľĒ too short.

Therefore, I had to cut the bottom portion off and add a horizontal plug halfway

up the pant. This caused all kinds

of problems with the curve of the pantsí trailing edge, but it did give me a way

to mount the kitís wheels by cutting off a portion of tire and gluing the rest

inside the pants. They also removed

the need for scratch building landing gear, except for the parts nearest the

wheels.

The radiator opening

consisted of scores of adjustable cooling louvers, which opened to let air in

and out of the radiator (not supplied) inside.

I made a radiator, sawed out the kitís closed louvers, and spent about a

week making new lower chins to the radiator housings and installing scores of

open louvers, which were individually fitted front, side, and bottom.

The kitís Fairey Reed metal props were supplied in metal.

These props were too

crude to use, and in any case were used only on the

dual control versions of the production run. I mated modified Stranraer props to

the metal spinners supplied in the kit.

Aligning the two nacelles was a critical step involving much shimming,

filling, sanding, and rescribing.

The Rams Head exhausts were molded

for the dual control Hendons and were incorrect for the early aircraft.

I cut them up, and fashioned them from the incorrect metal pieces

provided. This involved sawing,

supergluing, filling, sanding, losing tiny pieces in the rug, etc.

I cut slots in the sides of the nacelles and installed them at the end of

the build.

crude to use, and in any case were used only on the

dual control versions of the production run. I mated modified Stranraer props to

the metal spinners supplied in the kit.

Aligning the two nacelles was a critical step involving much shimming,

filling, sanding, and rescribing.

The Rams Head exhausts were molded

for the dual control Hendons and were incorrect for the early aircraft.

I cut them up, and fashioned them from the incorrect metal pieces

provided. This involved sawing,

supergluing, filling, sanding, losing tiny pieces in the rug, etc.

I cut slots in the sides of the nacelles and installed them at the end of

the build.

The Tail:

I made the vertical tails too short, and the horizontal tails too narrow

and two short, matching the prototype.

Once I saw my mistake(s), I sawed them up and added pieces of Evergreen

stock, resanding and reshaping everything.

(As with most incorrect model parts, itís often easier and quicker to

make correct parts from scratch.)

There was no provision to locate the tail on the fuselage, so I sanded a curved

profile to their mating surfaces and tube glued them to the rear fuselage.

This step went more smoothly than most steps in the assembly.

Finally, I made the struts from 30-year-old Airmodel strut material.

| COLORS & MARKINGS |

The entire exterior was

sprayed with Humbrol 114 (NIVO), followed by much clean up and respray, followed

by coats of gloss acrylic, decals, and flat acrylic.

Certain areas of the plane were brush painted with gloss to denote metal

surfaces.

| FINAL CONSTRUCTION |

Fuselage windows were cut from clear plastic sheet, and various details were fashioned from plastic strips, wire, and basswood. Structure for the canopy and turret came from decal strips.

| CONCLUSIONS |

I must say making this

aircraft gave me a huge amount of satisfaction. Building todayís super-detailed

kits is fun, but todayís modeling seems to be a battle to keep as much detail as

youíre given rather than creating it yourself.

In this case, I fashioned all the detail as well as a lot of the basic

shape of the model. I would have

used resin aftermarket stuff if I had the chance, but for better or worse, the

result is 95% my work, and thatís what vacuform modeling is all about.

I must say making this

aircraft gave me a huge amount of satisfaction. Building todayís super-detailed

kits is fun, but todayís modeling seems to be a battle to keep as much detail as

youíre given rather than creating it yourself.

In this case, I fashioned all the detail as well as a lot of the basic

shape of the model. I would have

used resin aftermarket stuff if I had the chance, but for better or worse, the

result is 95% my work, and thatís what vacuform modeling is all about.

March 2011

Copyright ModelingMadness.com. All rights reserved. No reproduction in part or in whole without express permission.

If you would like your product reviewed fairly and quickly, please contact the editor or see other details in the Note to Contributors.