Aeroclub 1/72 Felixstowe F2A

| KIT #: | 123 |

| PRICE: | £18.00 |

| DECALS: | Several options |

| REVIEWER: | Carmel J. Attard |

| NOTES: |

Vacuform with metal parts. |

| HISTORY |

Felixstowe flying boats were so named after the Royal Naval Air Station where they have evolved. Adopted from the Curtiss American series of flying boats with more efficient and sea worthy hulls designed by Squadron Commander John Porte of the RNAS. The first Felixstowe machine was the F1, originally called Porte 1 which was a rebuild from the Curtiss H4 serial No 3580. Only the wings and tail assembly were retained, the F1 being given Hispano Suiza engines and fitted with an entirely new hull. Evaluation of the machine proved soundness of Porte’s design. The next stage was to scale up the new hull to match the size of Curtiss H12 Large America.

The prototype F2 (8560) was a Curtiss

H12 with a Porte type hull. This went into production as the F2A powered by a

345hp Rolls Royce Eagle VIII engines, the first delivered in November 1917. By

March 1918 orders for the F2A had reached nearly 170. Just over 100 were

completed by Saunders and a further 10 by the Aircraft Manufacturing Company.

The prototype F2 (8560) was a Curtiss

H12 with a Porte type hull. This went into production as the F2A powered by a

345hp Rolls Royce Eagle VIII engines, the first delivered in November 1917. By

March 1918 orders for the F2A had reached nearly 170. Just over 100 were

completed by Saunders and a further 10 by the Aircraft Manufacturing Company.

The chief contractors which benefited from the experimental modifications initiated at Felixstowe were Saunders of Cowes, Isle of Wight; May Harden of Hythe, Southampton Water, Dirk Kerr and Co of South Shields; Short Brothers of Rochester and Phoenix Dynamo Manufacturing Co of Bradford who built the hulls at North Bank of the Humber for completion.

The F3 was a slightly larger aircraft than the F2A with a longer range and twice the bomb load and substantial orders were placed for it. The F3s were ordered in such quantities that it seemed that it was preferred to the F2A. By March 1918 more than 260 F3s had been ordered. These were powered with same engines as the F2A the excellent Eagle VIII water-cooled Vee-type but only 100 F3s were in fact completed. 96 being on RAF charge on the 31st October 1918. It is important to note that the allocation of serial numbers for batches of the F2As and F3s seem to indicate that orders for the two types were placed simultaneously.

The Malta connection

Ever since those early days there was

little that the Malta Dockyard could not do, and it came to no surprise when in

May 1917 it was decided to build the Felixstowe F3 seaplanes. UK production

could not cope with the demand and building the flying boats at Malta at the

dockyard would have the added advantage of eliminating the need of shipping

planes out from England.

Ever since those early days there was

little that the Malta Dockyard could not do, and it came to no surprise when in

May 1917 it was decided to build the Felixstowe F3 seaplanes. UK production

could not cope with the demand and building the flying boats at Malta at the

dockyard would have the added advantage of eliminating the need of shipping

planes out from England.

Local Maltese skilled labour was employed, the men who were expert boat builders from since the time of the Grandmasters of the Knights of St John, had no difficulty in making the simple Porte type hulls, besides, Maltese women were employed as fabric workers under the supervision of Lady Mathuen, the wife of the Governor of the island at the time. The first Maltese built F3 was completed in November 1917 and the first 11 were built there during the following 12 months.

The finished flying boats built at the Malta Dockyard would simply be towed out of the French creek at the dockyard facilities and flown to Kalafrana sea plane base to join the newly formed No 267 squadron. The first F3 serialled N4310 was completed in November 1917. It was powered by a Rolls Royce Eagle VIII engines. When the remaining sisters’ serialled N4311-N4321 were completed in November 1918 a further 38 were ordered but the number was subsequently reduced to 28. Eventually only 11 serialled 4360 to 4370 are recorded as having been delivered bringing the total number of seaplanes built at the Malta Dockyard to 23.

Both the F2A and the F3s were first

class flying boats capable of long range patrols. These carried two pilots and

an armament varying from four to seven Lewis machine guns, single or twin in

each of the front and rear cockpits, another above the pilot’s seat and

sometimes a beam gun either side. The 230 lb bombs could be carried under the

wings. During its patrol mission the Felixstowe F2A scored numerous successes

over enemy submarines and airships. By various improvements the F2A could carry

enough fuel for more than nine hours flying and in spring 1918 an alternative

attempt was made to increase the combat radius by

towing the aircraft on a

lighter behind a Royal Navy destroyer into the scene of action however little

operational use was made of this procedure. The fuel supply system was the major

weakness of the Felixstowe. This often obliged the crew to bring it down to the

sea.

towing the aircraft on a

lighter behind a Royal Navy destroyer into the scene of action however little

operational use was made of this procedure. The fuel supply system was the major

weakness of the Felixstowe. This often obliged the crew to bring it down to the

sea.

In summer of 1918 the dazzle paintwork was introduced on the F2A operating over the North Sea. In October 1918 there were 53 of these boats on RAF charge. One of these N65, an F2A with a lightweight hull and modified nose turret, was used operationally from Felixstowe and was involved in the destruction of Submarine UCI in July 1917.

The F2A, F3 Felixstowe flying boats were officially regarded obsolete in 1921 The F3 was therefore survived by the F2A, which with the F5 was a standard RAF type during the early 20s and set a pattern for British flying boats design that was not superseded for at least another 10 years. Felixstowe Items that survived almost 100 years and in perfect condition were two main propellers, one of which is proudly displayed at the Malta Aviation Museum at Ta’Qali, and another propeller is on display at the Fino furniture manufacturer at Imriehel which are within a mile of each other.

| THE KIT |

The kit comes in a sealed sturdy box

containing several vac-form sheets containing all the parts to make one complete

kit. Detail parts like the control columns, Eagle engine parts and propellers

are supplied in white metal. Decal sheet with several serial numbers for

different liveries are also supplied. A white metal be aching trolley adopted for

the Felixstowe used to be sold separately but at the time I bought the kit this

was out of stock and I made mine from plastic card with reference to scale plans

obtained from other source. The kit was designed by John Adams and is complete

in every detail. The kit has an unusual new method for forming the vac-form

wings. This consisted of mounting the wings at an angle so that the trailing

edge is drawn deeper into the mould relative to the leading edge, the wing will

thin in section towards the trailing edge. In doing so less plastic is required

to remove to achieve thinner trailing edge. A 12-page A4 size comprehensive

instruction is issued with the kit which explains in great detail all that is

required to build the scale model. This also includes accurate scale plans and

no less than six F2As side views for which markings are supplied and which are

finished in various liveries.

aching trolley adopted for

the Felixstowe used to be sold separately but at the time I bought the kit this

was out of stock and I made mine from plastic card with reference to scale plans

obtained from other source. The kit was designed by John Adams and is complete

in every detail. The kit has an unusual new method for forming the vac-form

wings. This consisted of mounting the wings at an angle so that the trailing

edge is drawn deeper into the mould relative to the leading edge, the wing will

thin in section towards the trailing edge. In doing so less plastic is required

to remove to achieve thinner trailing edge. A 12-page A4 size comprehensive

instruction is issued with the kit which explains in great detail all that is

required to build the scale model. This also includes accurate scale plans and

no less than six F2As side views for which markings are supplied and which are

finished in various liveries.

| CONSTRUCTION |

Wing parts were first scored and separated from backing sheet using a sharp modelling blade. Any waste plastic from the aileron spars on the wings were removed. The vac-form parts are thensanded in the usual manner until the desired thickness is obtained. The trailing edges needed thinning down and a ridge under the leading edge sanded smooth with a homemade sanding paper block. Final finishing was done with a smooth grade of wet and dry paper. The leading edge rounded to blend into top surface. Ailerons were treated in same fashion and sanding flat on the inside. Taiplanes, fin and rudder also treated in same way.

The fuselage halves are then drawn

around them with marker pen and scored using a sharp blade around each of the

items. Care is taken when coming around the bottom and under the rear fuselage

step. Parts

were then carefully broken from backing sheet. The retained little

plastic was removed from each part in turn and was test fit of the parts

together, checking with an outside caliper to check extent of sanding required.

At this stage the plastic around cockpit area was not removed. Once happy with

the general fit of the parts a razor saw removed excess plastic from the

cockpit, the nose gun position and lower wing seat.

were then carefully broken from backing sheet. The retained little

plastic was removed from each part in turn and was test fit of the parts

together, checking with an outside caliper to check extent of sanding required.

At this stage the plastic around cockpit area was not removed. Once happy with

the general fit of the parts a razor saw removed excess plastic from the

cockpit, the nose gun position and lower wing seat.

With the parts cut and shaped these were then held with tape and run liquid glue around the joint and reinforcing the joint with with strips of plastic on the inside. The bulkhead is added immediately in front of lower wing position. The planning bottom was then fixed in place, top decking cut out and test fitted. The lower wing was gently bent a dihedral at centre section, placed into position, checked for alignment and glued in place. Tail plane items all glued together. The fin was glued onto the fuselage using a scrap piece of rod as reinforcing spar, & the rudder added.

Engine detail parts all came in white metal, the struts to fix to them identified, those at the rear being slightly longer. The only tricky stage was mounting the engine. Once achieved then the whole top wing alignment is also correctly aligned. Engine cylinder block, exhaust pipes, propeller all in white metal were painted accordingly. The assembly and paint guide is well explained in the instructions. I used super glue to fix the engine mounts, lower struts etc. The radiators were then fitted to both engines. Wing floats added to the outer struts extensions. Assembly was allowed to dry overnight and rigging holes marked and drilled to apply the rigging. A time consuming process but this invisible thread rigging method in the end adds strength to the biplane mature of the F2A. The rectangular sails on the top wings were made from scrap plastic. The glazed wind shield was cut with scissors, trimmed and attached with PVA glue.

| COLORS & MARKINGS |

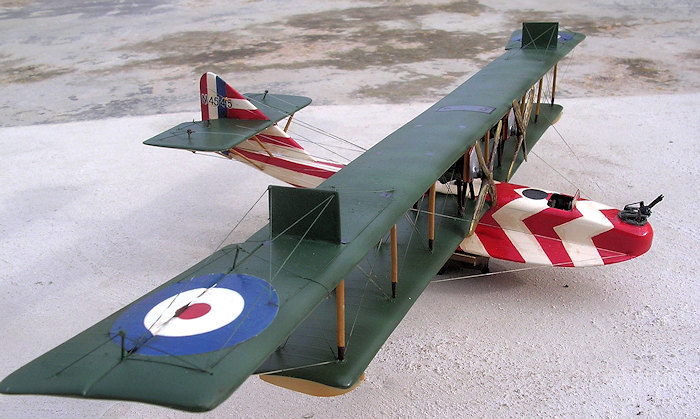

A very small number of boats were

Dazzle painted and were limited to the F2s at Great Yarmouth and Felixstowe

bases. This was mainly applied for ease identification by the other crew and was

to be an advantage during a mix-up. After this the pilot of each individual boat

was allowed to create his own pattern for the hull. The basic colors used were

mainly roundel colors, sometimes with an additional yellow, green and even

black. The colors on the F2A presented on my model N4545 had the hull and fin in

Dazzle paint with chevron and horizontal stripes in roundel red on white

background with a gloss finish. The wing and tail, struts, engine all finished

in standard colors of the era. Note the modification on the ailerons.

A very small number of boats were

Dazzle painted and were limited to the F2s at Great Yarmouth and Felixstowe

bases. This was mainly applied for ease identification by the other crew and was

to be an advantage during a mix-up. After this the pilot of each individual boat

was allowed to create his own pattern for the hull. The basic colors used were

mainly roundel colors, sometimes with an additional yellow, green and even

black. The colors on the F2A presented on my model N4545 had the hull and fin in

Dazzle paint with chevron and horizontal stripes in roundel red on white

background with a gloss finish. The wing and tail, struts, engine all finished

in standard colors of the era. Note the modification on the ailerons.

| CONCLUSIONS |

I have much enjoyed building the

Felixstowe particularly in view of its past history and its connection and ties

with the Malta Dockyard where I spent 32 years of my career in a senior post.

The kit also makes another addition to my ever growing list of flying boats all

at the scale of 1/72.

I have much enjoyed building the

Felixstowe particularly in view of its past history and its connection and ties

with the Malta Dockyard where I spent 32 years of my career in a senior post.

The kit also makes another addition to my ever growing list of flying boats all

at the scale of 1/72.

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.