Entex

1/72 DeHavilland No. 1 Biplane

| KIT #: | 8448 |

| PRICE: | $ |

| DECALS: | None required |

| REVIEWER: | Brian Baker |

| NOTES: |

First issued in the late sixties, sometimes seen at swap meets. |

| HISTORY |

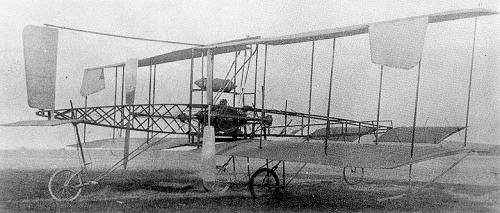

Geoffrey

DeHavilland’s first attempt at

building an airplane came in May, 1909, when he built his No. 1 Biplane in a

rented workshop from rough design sketches.

Mrs. DeHavilland did the fabric work, and F.T. Hearle helped with the

design and construction. In May,

1909, the semi-completed airplane was carried by truck (lorry) to Seven Barrows,

near Newbury, Berks, where an additional six months were consumed in final

adjustments before flight tests could be conducted.

The plane had a wing span of 36 ft., a length of

29 ft, and a gross weight of

850 lb., easily fitting into the current American Light Sport category. It was

powered by a 45 hp. DeHavilland Iris four cylinder water cooled engine driving

two opposite rotating metal props by means

of a chain drive mechanism. The

landing gear consisted of four bicycle wheels, two amidships, and one at either

end. There were two

horizontal surfaces, a fixed one at the rear, and a moveable unit in front.

A small rudder was above the rear airfoil, and lateral control was

achieved by small ailerons on the wingtips.

of a chain drive mechanism. The

landing gear consisted of four bicycle wheels, two amidships, and one at either

end. There were two

horizontal surfaces, a fixed one at the rear, and a moveable unit in front.

A small rudder was above the rear airfoil, and lateral control was

achieved by small ailerons on the wingtips.

The

plane’s career was very short lived.

In December, 1909, the first flight attempt met with disaster. To start

with, DeHavilland had never flown an airplane before, and this was his undoing.

He took off , but after becoming

airborne, he overcorrected on the elevator control, imposing excessive stress on

the wing structure. The wing failed,

and the plane crashed to the ground from a lofty altitude of fifteen feet.

DeHavilland was uninjured, but the plane was a total write-off. However,

the engine was salvaged for future use. Not an auspicious start, but DeHavilland

made up for it with his future creations, including the DH-4, Mosquito, Vampire,

and Comet, not to mention my favorite, the Tiger Moth.

| THE KIT |

The

instructions are printed on a large sheet, consisting of three 8 ˝ by 11 inch

sheets, covering all three aircraft.

In this case, the Entex kit, No. 8448, includes the Voison, (Voisin?),

Antoinette, and Dehavilland No.1.

All of the parts are listed by number and f unction, while a strip drawing shows

the assembly steps in recommended order.

There are no decals, and the only painting required is on the wooden and

metal components, such as the major fuselage structures, engines, wheels, and

propellers.

unction, while a strip drawing shows

the assembly steps in recommended order.

There are no decals, and the only painting required is on the wooden and

metal components, such as the major fuselage structures, engines, wheels, and

propellers.

| CONSTRUCTION |

I trimmed

all of the components, and immediately applied the ‘Aeroskin” fabric to the wing

panels, elevators, and rudder. The

fuselage assembly came next, with a couple of small rectangular braces in the

forward part, giving it a measure of rigidity.

Next came the engine, which consisted of a small cylindrical shape with trunnions similar tothose on an old cannon.

The engine mounts on two small “engine stands” which are glued to the

lower fuselage longeron. The

location of the engine is not too clear

in the instructions, and this is

critical because the engine has to line up with the chain drives, which are

mounted to the rear, and which connect to a pair of struts which are attached to

the rear spars of the lower wings.

The problem is that the instructions say to mount the lower wing to the

fuselage, but the instructions imply that both spars are to be attached to the

lower fuselage. This creates a much

lower almost zero angle of incidence, whereas the actual wing has a fairly high

angle, and the rear spar has to hang free to achieve the proper angle.

in the instructions, and this is

critical because the engine has to line up with the chain drives, which are

mounted to the rear, and which connect to a pair of struts which are attached to

the rear spars of the lower wings.

The problem is that the instructions say to mount the lower wing to the

fuselage, but the instructions imply that both spars are to be attached to the

lower fuselage. This creates a much

lower almost zero angle of incidence, whereas the actual wing has a fairly high

angle, and the rear spar has to hang free to achieve the proper angle.

I ended up building up the biplane

wing structure and then attaching the whole thing to the fuselage, lining things

up with the prop mounting struts. I

had to enlarge all of the strut mounting holes with a drill, taking care not to

drill through the other side of the wings.

The struts can be attached with Tenax or any liquid solvent.

Once the wing structure was attached, and the chain drive was lined up

properly, I attached the forward elevator and tailplanes. The landing gear and

wheels were tedious to install, but when this was accomplished, the model was

ready to sit on its wheels. The

props went on last, and these merely were glued to the crankshafts.

No spinning props on this baby.

I added a seat belt to the seat, and the model was ready to rig.

| FINAL CONSTRUCTION |

| CONCLUSIONS |

February 2012

Thanks to If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.