Roden 1/48 Airco DH.4

| KIT #: | 422 |

| PRICE: | $30 at a prominent retailer |

| DECALS: | Three options |

| REVIEWER: | Scott Lyle |

| NOTES: |

| HISTORY |

Having just

built a model of one of the most advanced bombers in the world, the B-1B Lancer,

I thought it would be fun to build a model of a World War 1-era bomber.

Perhaps the most famous bomber of that era was the

German  1/48 kit (that I can afford) of that bird doesnít exist, I

had to search for other alternatives.

Rodenís line of 1/48 Airco DH.4 kits fit the bill

nicely.

1/48 kit (that I can afford) of that bird doesnít exist, I

had to search for other alternatives.

Rodenís line of 1/48 Airco DH.4 kits fit the bill

nicely.

The DH.4 had a successful career during the war as a

single-engine day bomber.

Designed by Geoffrey de Havilland, it was sturdy, easy

to fly, and had such high speed that it could perform its bombing missions

without fighter escort.

First appearing during the spring of 1917, it was

supposed to be replaced by the DH.9 during 1918, but problems with that aircraft

kept the DH.4 in front-line service for the remainder of the war.

The DH.4 was very widely produced with some 1,400 being

built in

| THE KIT |

Rodenís

kit comes molded in light gray plastic with a small transparent sheet to provide

the small windscreens and the transparent sections in the upper wing.

In my boxing the parts were very well molded, with the

fuselage and wings exhibiting very subtle but natural-looking surfaces.

One criticism is that there are no locating pins on the

parts that we modelers are accustomed to having them on, like the fuselage

halves.

A plus is that different sized bombs are provided, allowing you to load

out your DH.4 in different ways.

Decals are provided for three different bombers, and

since there are some substantial differences between the three, you have to

decide which one youíre going to build fairly early in the process.

I choose to build N9557 of the Royal Navyís No.202

Squadron, if for no other reason than its cool ďIím thumbing my nose at youĒ

artwork on the tail.

Rodenís

kit comes molded in light gray plastic with a small transparent sheet to provide

the small windscreens and the transparent sections in the upper wing.

In my boxing the parts were very well molded, with the

fuselage and wings exhibiting very subtle but natural-looking surfaces.

One criticism is that there are no locating pins on the

parts that we modelers are accustomed to having them on, like the fuselage

halves.

A plus is that different sized bombs are provided, allowing you to load

out your DH.4 in different ways.

Decals are provided for three different bombers, and

since there are some substantial differences between the three, you have to

decide which one youíre going to build fairly early in the process.

I choose to build N9557 of the Royal Navyís No.202

Squadron, if for no other reason than its cool ďIím thumbing my nose at youĒ

artwork on the tail.

| CONSTRUCTION |

Construction

starts off with the cockpit per usual, and like most World War 1 aircraft,

things are pretty simple in the ďofficeĒ.

Manned by a crew of two, there were actually two

offices, both consisting of wooden floorboards, seats, control sticks, and

rather sparse instrument panels.

Roden captured that detail nicely, and I first painted

all of the wood parts Testors Acrylic

The instructions call for the fuselage side walls to be

painted in a linen color, but references point out that the forward part of the

DH.4 was constructed of thin plywood, so I painted the sidewalls with my wood

paint procedure as well.

I donít know if thatís accurate or not as the plywood

could have been painted any color, but without extensive references, I blindly

proceeded.

The details on the instrument panels were picked out by hand, and

then I started assembling the various parts together.

The instructions call for the fuselage side walls to be

painted in a linen color, but references point out that the forward part of the

DH.4 was constructed of thin plywood, so I painted the sidewalls with my wood

paint procedure as well.

I donít know if thatís accurate or not as the plywood

could have been painted any color, but without extensive references, I blindly

proceeded.

The details on the instrument panels were picked out by hand, and

then I started assembling the various parts together.

I attached some photo etch seatbelts from my spares box

to both the pilotís seat and the rear gunnerís stool, and then those parts were

attached to their respective floorboards, along with the control sticks and

rudder bars.

Next I glued the fuselage halves together; a step during which

you have to pay careful attention.

There are no locating pins, and the box-shape of the

fuselage is very open on top, meaning the only real seam to apply glue to is on

the bottom.

The assembly is fairly weak until you start gluing on the top

portions of the fuselage.

While the instructions specify that you glue the various

cockpit parts to one of the fuselage halves before you close them up, you donít

have to do it that way.

Since the whole thing is open on top, you can easily fit

everything in from above.

Without locating pins the placement of the top parts is

rather ambiguous, so I first glued the horizontal stabilizer onto the rear (it

actually had locating pins).

With that in place the upper part that covers the rear

fuselage was butted up against it and glued in place, and in that fashion I

worked my way forward from back to front.

In a couple of nights the fuselage was complete and

fully loaded with wood-painted WW1 stuff.

The fit of the parts isnít perfectly precise, especially

around the engine, so you have to do a lot of test-fitting and use your modeling

skills.

Still, in short order the fuselage was finished and I moved on to the

wings.

I attached the pilotís cockpit to the lower wing per the in structions,

and then glued the lower wing to the fuselage.

The joint only needed a quick swipe of Mr. Surfacer 500

to fill any gaps.

Up next I attached the landing gear (without the

wheels), and then started planning how to attach the upper wing.

structions,

and then glued the lower wing to the fuselage.

The joint only needed a quick swipe of Mr. Surfacer 500

to fill any gaps.

Up next I attached the landing gear (without the

wheels), and then started planning how to attach the upper wing.

I wanted to assemble the wing struts and rig them

without having to glue the upper wing in place (for painting reasons), and

luckily the four struts around the cockpit attach firmly into pockets in the

fuselage.

When those were set up I set the upper wing temporarily in place

on those using Tamiya masking tape, and that allowed me to snap the rest of the

wing struts into place Ė a credit to the kitís engineering.

I glued the lower ends of each strut in place (but not

the upper ends) and then set the model aside to dry overnight.

The next night I removed the upper wing and then used

stretched sprue to rig the wing struts.

The DH.4 has a lot of rigging, so this process Ė not my

favorite part of model building by the way - took a few nights!

At any rate with the lower wing covered in fragile struts and rigging, the model was now ready for paint. It was going to be a challenge to keep from knocking some of those struts off during the painting process.

| COLORS & MARKINGS |

I first wiped the model down with Polly

Sís Plastic Prep, and then airbrushed a primer coat using Mr. Surfacer 1000.

I then pre-shaded the few panel lines that there were

with Tamiya XF-1 Black.

The first color to go on was the light gray on the

engine panels (per the version I was modeling), for which I used Testors

Camouflage Gray.

I masked that off and then lightly airbrushed Testors Sand onto

the undersurfaces to simulate the Clear Doped Linen color so ubiquitous on

British WW1 aircraft.

Letting that dry for a night I masked that off and then

applied the equally ubiquitous Dark Green PC10 shade to the upper surfaces using

Tamiya XF-62 Olive Drab.

That was lightened slightly and then misted on randomly

to provide a faded effect.

The wing struts were brush-painted to look like wood

using my wood painting process as detailed above, and then a coat of Future was

airbrushed over the whole model to prepare it for the decals.

Tamiya XF-62 Olive Drab.

That was lightened slightly and then misted on randomly

to provide a faded effect.

The wing struts were brush-painted to look like wood

using my wood painting process as detailed above, and then a coat of Future was

airbrushed over the whole model to prepare it for the decals.

The kitís decals proved to be a challenge.

They were thick and didnít settle down over surface

details like decals usually do, even with a strong solvent like Walthers

Solvaset.

They also cracked and tore easily Ė very frustrating!

I knew I was going to have to touch up a lot of the

decals with paint later, something I donít like to do because itís hard to match

the color of the paint precisely with the color of the decal.

With the decal step completed I sealed them with another

coat of Future, and then applied a wash of Mig Productions ďDark

| FINAL CONSTRUCTION |

With the painting step largely done it was time to

finish the modelís construction.

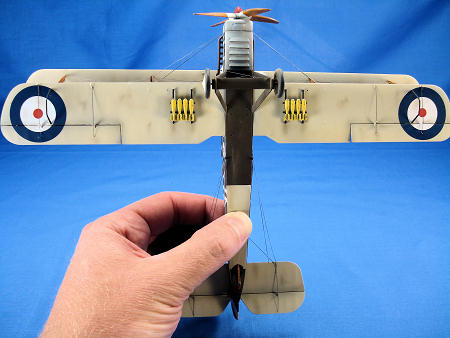

I glued the upper wing into place and also attached the

forward machine gun, bomb racks, and wheels.

I ďzingedĒ the rigging between the wings with matches,

and

then it was time to attach the rest of the rigging, of which there was

plenty.

The tail section is covered in rigging, and then there is a maze of

lines leading from the cockpit to the tail as well.

I used more stretched sprue as well as some EZ Line to

finish the job.

With that done I glued on the final parts, consisting of the rear

machine guns, wing skids, and the prop.

I dusted some earth colored pigments onto the wheels and

tail skid, and declared the model complete.

then it was time to attach the rest of the rigging, of which there was

plenty.

The tail section is covered in rigging, and then there is a maze of

lines leading from the cockpit to the tail as well.

I used more stretched sprue as well as some EZ Line to

finish the job.

With that done I glued on the final parts, consisting of the rear

machine guns, wing skids, and the prop.

I dusted some earth colored pigments onto the wheels and

tail skid, and declared the model complete.

| CONCLUSIONS |

Rodenís

DH.4 is well engineered and goes together quickly.

The detail and ďdelicatenessĒ of the biplane is

excellent, and the ability to build three different versions is also admirable.

The one big fly in the ointment is those decals.

I felt they damaged the overall look of the finished

model, and unnecessarily so.

In this day and age I expect any kit from a major

producer to have decals that perform properly, and I donít think thatís an

unreasonable demand.

While I certainly would build another Roden kit in the

future, I would make sure I had a set of applicable aftermarket decals on hand

before I began.

| REFERENCES |

-

Profile Publications #26, ďThe de

Havilland D.H.4Ē

-

Wikipedia, the Online

Encyclopedia

August 2011

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.