1/72 AGO C.II

| KIT #: | |

| PRICE: | |

| DECALS: | Home made with printer |

| REVIEWER: | Stephen Foster |

| NOTES: | Scratch built |

| HISTORY |

The Ago Fluggesellschaft

Gmbh of Johannisthal was established in 1912 as the Berlin branch of the

Flugzeugwerke Gustav Otto. Otto was a Bavarian engineer and early

pioneer of flight and developed a series of very similar designs known

collectively as Doppeldekkers. Unfortunately for Otto the Prussian air

service would not accept the Doppeldekker design for military service as

it was considered to be structurally too weak, so although some machines

did serve with Bavarian air units, the military market was limited.

(Some modellers and other authors have given the designation CI to the

Doppeldekker. This is incorrect as these machines were never fitted with

a permanent armament). In early 1915 Otto produced a new design based on

a pusher layout with a central nacelle as on the Doppeldekker, but with

twin booms instead of an open tail. This left the observer with a wide

field of fire if armed with a machine gun on a flexible mounting. The

booms were made from two moulded plywood shells joined at the centre,

giving a much stronger airframe. Both the army and the navy ordered land

planes in early 1915, and the first CI

airframe was delivered to the

Army in April of that year. This aircraft became the first machine to

receive the C designation, meaning that it was the first armed

two-seater, being equipped with a Parabellum machine gun on a ring

mounting in the front cockpit. Production machines followed but because

Ago was a relatively small company the total number of CI machines

produced was probably only around 64. Nevertheless it was a type that

proved to be robust and had a long active service on both the western

and eastern fronts, the last machines being recorded in service with

front line units in April in 1917 thereafter they were used by training

units. It was popular with crews as it was relatively easy to fly and

could withstand damage and still return to an airfield. The Ago types

were initially reported as twin engined and more heavily armed than they

actually were, but even when they were recognised as single engined

pushers, they were treated with respect by Allied pilots. It was only

later in their service when tractor fighters were introduced that the

inherent weaknesses of the pusher layout became important and the type

had to be withdrawn from front line service.

airframe was delivered to the

Army in April of that year. This aircraft became the first machine to

receive the C designation, meaning that it was the first armed

two-seater, being equipped with a Parabellum machine gun on a ring

mounting in the front cockpit. Production machines followed but because

Ago was a relatively small company the total number of CI machines

produced was probably only around 64. Nevertheless it was a type that

proved to be robust and had a long active service on both the western

and eastern fronts, the last machines being recorded in service with

front line units in April in 1917 thereafter they were used by training

units. It was popular with crews as it was relatively easy to fly and

could withstand damage and still return to an airfield. The Ago types

were initially reported as twin engined and more heavily armed than they

actually were, but even when they were recognised as single engined

pushers, they were treated with respect by Allied pilots. It was only

later in their service when tractor fighters were introduced that the

inherent weaknesses of the pusher layout became important and the type

had to be withdrawn from front line service.

The German navy showed an

interest in the type from the start and ordered land plane variants in

early 1915. In May 1915 the first floatplane was delivered to the navy

where it was used for training in bombing and machine gunnery. The CI

types were usually powered by either 150hp Benz Bz III and later 160hp

Merceedes DIII engines; early machines had radiators mounted on the

nacelle sides, but later the radiators were joined and moved under the

top wing. In late 1915 the CI was replaced by the CII with the more

powerful Benz Bz IV engine. Some CII machines had an extended wingspan

with a third bay added. The navy accepted several of the extended wing

CII's which were fitted with floats and these were used for maritime

reconnaissance and bombing, and later training. These seem to have been

in service for most of 1916 and may not have been withdrawn from front

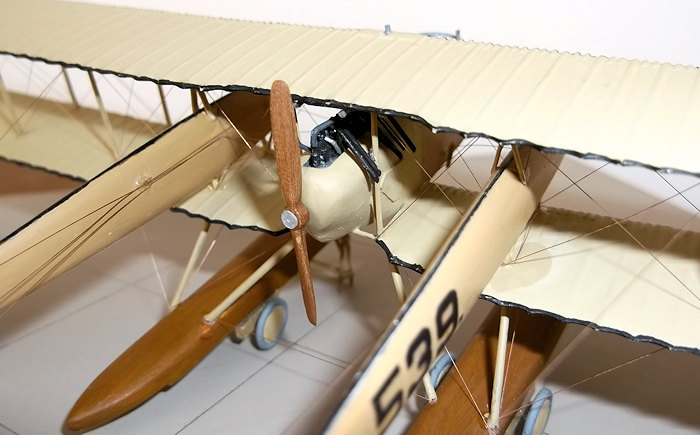

line service until 1917. The aircraft depicted in the model is of 539

which was photographed at an unidentified naval station, probably in

1916. This machine was powered by a Benz B IV engine and had the gravity

tank mounted on the starboard side away from the exhaust manifolds. Agos

were delivered and flown painted in a brown dope with the wood booms

either left in wood or painted to match the linen.

Merceedes DIII engines; early machines had radiators mounted on the

nacelle sides, but later the radiators were joined and moved under the

top wing. In late 1915 the CI was replaced by the CII with the more

powerful Benz Bz IV engine. Some CII machines had an extended wingspan

with a third bay added. The navy accepted several of the extended wing

CII's which were fitted with floats and these were used for maritime

reconnaissance and bombing, and later training. These seem to have been

in service for most of 1916 and may not have been withdrawn from front

line service until 1917. The aircraft depicted in the model is of 539

which was photographed at an unidentified naval station, probably in

1916. This machine was powered by a Benz B IV engine and had the gravity

tank mounted on the starboard side away from the exhaust manifolds. Agos

were delivered and flown painted in a brown dope with the wood booms

either left in wood or painted to match the linen.

| CONSTRUCTION |

I started by constructing the booms. The profile of the booms was traced from the plan on to 30 thou card and two sections per boom cut out. then two other sections were cut from 20 thou card and a laminate made of two x 30 and one 20thou card. This was compressed with a pile of books while the glue dried, and then the booms were shaped with glass paper until the correct profiles were achieved. The fins and rudders were cut from 20 thou card and glued into place when the booms were ready.

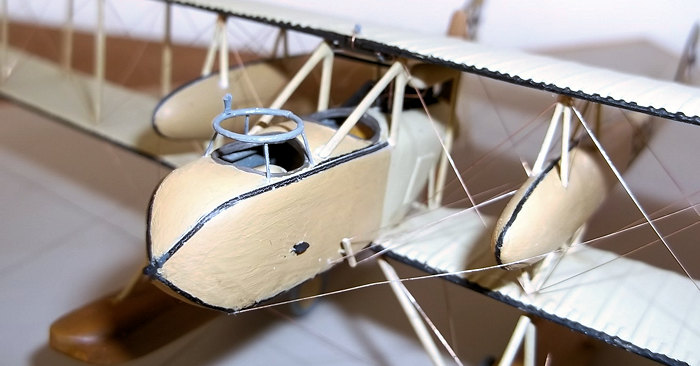

The nacelle was made from

a push mould - a male mould was carved from balsa and a female was cut

in a sheet of plywood. 30 thou card was pinned over the hole in the

plywood and the male mould used to make two halves of the fuselage

nacelle. The halves could then be cut from the plastic sheet and the

edges sanded and smoothed until the correct size was made. The cockpit

and engine holes were cut out and filed smooth. The interior of the

cockpits was constructed from plastic rod and card and consisted of a

simple framework for the nacelle, seats, floors, control column and

rudder bar and two thicker pieces of rod behind the pilot to represent

bomb chutes. The interior of the cockpit was painted wood for the

floors, brown for the seats and natural linen for the sides. The frame

was painted black as this was steel tube not

wood. A small aperture was

cut out under the nose to represent the pilot's window, the glass being

represented by a small piece of acetate cut from a bubble pack. When the

cockpit was ready the floor was cemented to one nacelle half and the

other joined. The corners of the moulding were rounded but one of the

distinctive features of the Ago was the square section of the nose and

bottom of the nacelle. To get rid of the rounded corners I cemented thin

strips of heat stretched sprue along the rounded edges and when this was

dry filled the gaps between the sprue and side with filler. When this

was rubbed down neat square edges were made. Various holes were drilled

into the nacelle to take struts later, the propellor shaft and the rear

spar at the back of the nacelle.

wood. A small aperture was

cut out under the nose to represent the pilot's window, the glass being

represented by a small piece of acetate cut from a bubble pack. When the

cockpit was ready the floor was cemented to one nacelle half and the

other joined. The corners of the moulding were rounded but one of the

distinctive features of the Ago was the square section of the nose and

bottom of the nacelle. To get rid of the rounded corners I cemented thin

strips of heat stretched sprue along the rounded edges and when this was

dry filled the gaps between the sprue and side with filler. When this

was rubbed down neat square edges were made. Various holes were drilled

into the nacelle to take struts later, the propellor shaft and the rear

spar at the back of the nacelle.

The engine was made from laminated plastic card for the engine block, rod for the cylinders and thinner rod for the exhausts. The carburettor and inlet pipes were also made from card and rod. The engine block was painted aluminium (silver with a dash of medium grey added), the cylinders and exhausts were black. When the engine was complete it was placed carefully into the fuselage nacelle and glued to a small shelf which had been put in earlier for the purpose.

The tail surfaces were

made from 20 thou card cut to shape with ribs added to the horizontal

surface as per the wings. The wings were cut from 30 thou card which had

been bent by placing a sheet of card into a waste pipe which was sealed

at one end. Near boiling water was poured into the tube and then emptied

after 10-15 seconds. When the wing blanks had been cut and sanded to an

aerofoil section, the rib spacings were marked with a fine pencil using

the plan as a guide, and strips of 10 x 20 thou card glued on to the

upper surfaces. These were then sanded down until only slight ridges

remained, and these were sealed with white paint. The riblets on the

leading edges of the wings were cut from stretched sprue and they too

were then sanded and painted. The ailerons were cut out of the top wing

and the trailing edge droop added by cementing a short piece of 10 x 20

thou card on the trailing edge and when dry sanding the upper surface

and adding filler around the edges of the card and shaping the lower

surface. The ailerons were then cemented to the wing at slight angles to

give a more realistic look to the finished model. Holes were drilled for the strut location points in the top wing and for the struts and float

struts in the lower wing. The struts were cut from 20 x 30 thou strip

and shaped to aerofoil section. The cabane struts were cut in one piece

from 30 thou card and sanded to shape. A gravity fuel tank was shaped

from a piece of sprue and two holes drilled, one at each end, to take

the sprue pins which would attach it to the struts later.

the strut location points in the top wing and for the struts and float

struts in the lower wing. The struts were cut from 20 x 30 thou strip

and shaped to aerofoil section. The cabane struts were cut in one piece

from 30 thou card and sanded to shape. A gravity fuel tank was shaped

from a piece of sprue and two holes drilled, one at each end, to take

the sprue pins which would attach it to the struts later.

The floats were made from 30 thou card for the top with a series of supports along the floats so that a support formed the rear edge of the steps. The sides were shaped from 20 thou card which was glued to the top of the float and the interior supports. When this was dry the front and rear ends were gently curved and cemented in place, followed by the bottoms which were in three sections and from 10 thou card scored to represent the keels. A little filler had to be added to some of the joins and the whole sealed with paint. These were then given a coat of Revell acrylic Ockre (88) as primer and then painted in oils: I used a mix of burnt sienna and raw sienna in a ratio of approximately 2:1. The oil paints took three days to dry in my airing cupboard because we had some dull cool days at the time. I then coated the floats with Revell clear orange acrylic varnish (730) - I applied 6 coats before I had a nice smooth finish. Finally the strut holes were drilled in the floats, and struts cut from 40 thou rod. These are slightly over scale in thickness but strength has to be considered here. I could have used brass rod but that would have presented other problems.

Assembly began by attaching the lower wings to the fuselage. This joint is small and consequently potentially weak, but I strengthened it by drilling two small holes in the inner edges of the wings and one in the lower rear of the fuselage nacelle. I then inserted a steel pin through the nacelle and into each lower wing. This requires very careful measurement and drilling but it was successful and undoubtedly helps to strengthen the joint. The wing to fuselage struts were glued into place and the model was ready for the main painting stage.

| COLORS & MARKINGS |

The basic colour was a mix

of approximately 3 parts Humbrol clear doped linen (HB 103) and 2 parts

natural wood (HB 94). The front of the nacelle and booms were Revel

acrylic Ockre (88). The struts were all painted in the same basic colour

mix with a little extra natural wood added, as was the rear of the

fuselage nacelle - all of these were painted metal on the real aircraft.

The black lining on the booms and flying surfaces were painted with a

fine paintbrush and steady hand! The crosses were printed on my home

computer, as was the serial on the sides of the booms. These were

applied at this stage.

The basic colour was a mix

of approximately 3 parts Humbrol clear doped linen (HB 103) and 2 parts

natural wood (HB 94). The front of the nacelle and booms were Revel

acrylic Ockre (88). The struts were all painted in the same basic colour

mix with a little extra natural wood added, as was the rear of the

fuselage nacelle - all of these were painted metal on the real aircraft.

The black lining on the booms and flying surfaces were painted with a

fine paintbrush and steady hand! The crosses were printed on my home

computer, as was the serial on the sides of the booms. These were

applied at this stage.

| FINAL CONSTRUCTION |

With the painting finished

it was time to make the underwing radiator and associated plumbing. The

radiator was made from two lengths of rod for the sides and short pieces

of 20 thou card for the cooling vanes. Rod also provided the material

for the pipes from the header tank in the top wing and from the rear of

the port (left) pipe to the engine compartment. These parts were

assembled and painted dark grey before the radiator was attached to the

underside of the top wing. Now the outboard wing struts were cemented to

the lower wing, as were the forward and rear cabane struts on the

fuselage. Small drops of glue were placed into the strut holes on the

upper wing and the latter was gently lowered on to the struts: all of

this was carried out as one operation to allow fine adjustment of the

struts into the holes in the upper wing. The wing was then weighted with

small weights, (pots of paint in my case), and allowed to dry out

overnight. This structure is strong enough to allow the remaining struts

to be inserted carefully the next day. I have used this method of

construction on all of my pusher models (I have 7 others), and it allows

correct

alignment to be achieved while not trying to do too much at once

and running into problems. With the wing struts in place it was time to

complete the plumbing of the radiator with the pre-cut and painted

pipes.

alignment to be achieved while not trying to do too much at once

and running into problems. With the wing struts in place it was time to

complete the plumbing of the radiator with the pre-cut and painted

pipes.

Now for the booms. This

requires more care than ever if the model is to be a success: I drilled

the holes in the booms for the struts and cut and fitted the latter

before attempting to fix the booms to the wings. Very careful

measurement is needed here to get position and alignment correct. I also

drilled two very small holes in the insides of the booms and the

horizontal tail surface so that I could insert short pieces of thin

stretched sprue to act as pins to strengthen what would otherwise be a

very weak joint. (I was glad that I did because later I had a mishap and

one of the booms twisted out of alignments and had to be re-attached to

the wing: the tail surface joint also had to be repaired and the pins

were helpful in bringing this section back into its correct location.

Scratch-building comes with its problems just like any other form of

modelling, no matter what the finished product may look like). I joined

the booms to the horizontal tail surface first, and while this was still

drying inserted the booms into the spaces between the wings. I had

placed drops of glue into the holes in the wings, so the boom struts

were able to drop into these holes and were held straight away. The rear

of the booms were held up by plastic card piles and the sides were

supported with paint tins again - the whole was a bit of a Heath

Robinson jig but I had practised beforehand to work out exactly what was

required and had everything ready: it took half an hour to prepare the

assembly and five minutes to complete it. Planning is always worth

while. I left the whole structure to dry out over night before I

attempted to handle it again. Now the floats could be fitted. Careful

measurements were made using a pair of dividers for the lengths of rod

required. These were then cut and inserted into the holes which had been

drilled in the tops of the floats

and allowed to dry. Then one float at

a time was fixed to the underside of the wings and fuselage and allowed

to dry out completely. The struts were painted after the floats were in

position. Final details including the control horns on the fuselage and

tail and step on the fuselage side were added before the rigging

started.

and allowed to dry. Then one float at

a time was fixed to the underside of the wings and fuselage and allowed

to dry out completely. The struts were painted after the floats were in

position. Final details including the control horns on the fuselage and

tail and step on the fuselage side were added before the rigging

started.

I rig my models with 40 SWG copper wire which is rolled straight with a piece of brass strip on a wooden block and attached with superglue. I measure each length from the model using a pair of dividers and start with the short sections between the boom struts as these are the least accessible. These were followed by the rear of the wings and between the front and rear pairs of struts. The control cables on the insides of the booms were next, followed by the tail surfaces and supports. The the control wires from the booms to tail were fitted, followed by the front of the wings except for the inner bay between the booms and nacelle. Here the control wires were fixed before the bracing wires. Finally the floats were rigged followed by the anti- drag wires at the front and rear. To finish the model I added the raised gun ring over the observer's cockpit and a propellor which I had carved from a piece of strip wood.

| CONCLUSIONS |

I have made or converted many pusher types and this one was the most difficult so far because of the boom structure. In addition I made life a bit more difficult for myself by making it a floatplane - a simple V undercarriage would have been easier. Making the parts was no more difficult than making parts for super-detailing or conversions and would be well within the capabilities of an experienced modeller. Careful and repeated measurement, and careful thought and pre-planning meant that no problem was insuperable and the whole model went together remarkably well in the end. This aircraft is available as a vacuform but the assembly would not be any easier - patience and care will still be needed for a successful model to result. However I now have a German single engined pusher in my collection and a type which is little known and rarely seen in model shows, so it was well worth the effort.

| REFERENCES |

The best source of information and plans for this machine is the DataFile number 75. This is for the CI variants - the CII extended wing was exactly 60 feet which in scale means 10 inches so it is easy to enlarge. The lower wing span is increased by the same amount as the upper wing - all the other dimensions remained the same. I estimated the float dimensions from a drawing and from an excellent photo of 539, both of which I found on the net. K. Munson's Bombers 1914-1919 in the Blandford colour series also provided some background information. There are various pieces of information scattered around a number of websites, one of the more useful being flyingmachines.ru but it is relatively easy to find information on this type.

6 June 2016

C

opyright ModelingMadness.comIf you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.