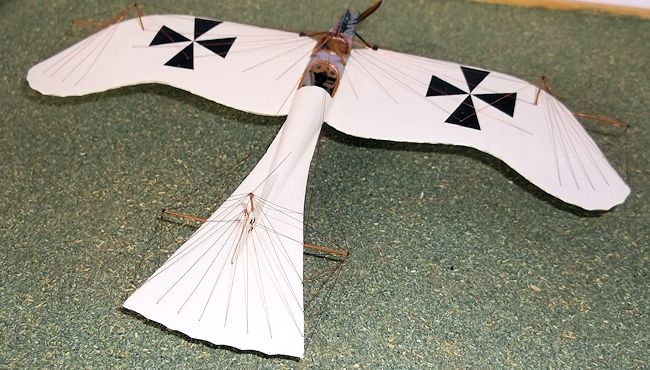

Pegasus 1/72 Etrich Taube

| KIT #: | 4010 |

| PRICE: | approx £10 |

| DECALS: | None |

| REVIEWER: | Stephen Foster |

| NOTES: | Short run kit |

| HISTORY |

Taube means pigeon or

dove in German and the name is derived from the shape of the wings, although the

original inspiration for this planform came from the leaf of the Zanonia palm.

Igo Etrich was an Austrian who through a series of designs in the first decade

of the 20th century eventually built an aeroplane that became the forerunner of

the later Taube models. Although Etrich produced a number of prototypes, it was

the two seat design which was produced in significant numbers, although every

machine was different as each one was hand-built, and each was an attempt to

improve on its predecessor. Later other companies in Germany produced similar

aircraft, also called Tauben, but many of these were of simpler construction and

had the underwing spar and spar extensions deleted and a markedly reduced amount

of rigging, all of which reduced drag and increased speed.

and

warping of the wing tips and horizontal tail surface. It was for this reason

that the trailing edges of these machines were very thin: only the forward

three-quarters of the wing had a double thickness of fabric covering while the

the trailing section was a single surface. The undercarriage was in the form of

a twin-forked structure similar to the contemporary designs of L. Bleriot. The

engines varied from 70 to 120 hp, the most numerous being built by Mercedes or

Argus. Radiators were mounted on the front sides of the fuselage and machines

were unarmed. Taube types were used in the early months of the Great War but

were withdrawn in early 1915. Those that were used operationally had for the

most part the simplified structure of the later designs with the underwing spar

removed and a simpler V undercarriage. Lt. von Hiddesen dropped some very small

bombs on Paris in September 1914 from a Taube, and it was a Taube machine that

brought news of the Russian armies movements in East Prussia that led to the

Battle of Tannenburg in 1914. A Taube also carried out reconnaissance sorties

for the German garrison at the siege of Tsingtao in Eastern China in 1914.

Tauben also served in the air units of the Austro-Hungarian armies, although

like their German counterparts they were withdrawn from front line service in

the spring of 1915 but continued to be used for training for about a year

afterwards.

and

warping of the wing tips and horizontal tail surface. It was for this reason

that the trailing edges of these machines were very thin: only the forward

three-quarters of the wing had a double thickness of fabric covering while the

the trailing section was a single surface. The undercarriage was in the form of

a twin-forked structure similar to the contemporary designs of L. Bleriot. The

engines varied from 70 to 120 hp, the most numerous being built by Mercedes or

Argus. Radiators were mounted on the front sides of the fuselage and machines

were unarmed. Taube types were used in the early months of the Great War but

were withdrawn in early 1915. Those that were used operationally had for the

most part the simplified structure of the later designs with the underwing spar

removed and a simpler V undercarriage. Lt. von Hiddesen dropped some very small

bombs on Paris in September 1914 from a Taube, and it was a Taube machine that

brought news of the Russian armies movements in East Prussia that led to the

Battle of Tannenburg in 1914. A Taube also carried out reconnaissance sorties

for the German garrison at the siege of Tsingtao in Eastern China in 1914.

Tauben also served in the air units of the Austro-Hungarian armies, although

like their German counterparts they were withdrawn from front line service in

the spring of 1915 but continued to be used for training for about a year

afterwards.

| THE KIT |

I have built a large

number of conversions recently, particularly pusher types and I wanted to try

something a little different so I thought that a tractor monoplane would be a

good idea. There is a vacuform of the Taube which was released in the 1970's

which is now a very rare bird, but I am not a fan of vacuforms so I bought a

Pegasus injection moulded kit instead. The notice on the box says that this kit

is not a toy and is only recommended for experienced modellers

and collectors: I had been warned. The kit consists of

some trees with plastic parts and some white metal parts for the fuselage

bulkheads, control column, fuselage pylons and undercarriage legs and what

passes for an engine. The spar extensions and struts, axle and exhaust pipes

have to be cut from plastic rod and strut material provided.

Instruction

number one states remove all parts from the trees and clean them up. The plastic

in this kit is fairly soft so this procedure needs care but is straightforward

with a sharp knife. In some cases I cut the trees with a saw and then removed

the part with a knife before finishing with a file and glass paper: stage one

took an evening to complete. This may be a relative small model with a limited

number of parts but is certainly not a quick build. The parts are well moulded

for a limited run kit, and except for the engine the white metal parts are a

good idea as they add strength to the model and provide better pieces to work

with. The engine is a bit crude but as it is mostly concealed this can be

overlooked by all except the most fastidious modeller. There is a problem with

the wings and tail surfaces however as they are much too thick, especially the

trailing edges, but unless you are prepared to spend another evening sanding

them down this problem is best treated by sanding some of the plastic and

leaving the rest, as much for strength as any other reason. I did replace the

vertical tail surfaces as these were too thick and not really of the correct

shape.

Instruction

number one states remove all parts from the trees and clean them up. The plastic

in this kit is fairly soft so this procedure needs care but is straightforward

with a sharp knife. In some cases I cut the trees with a saw and then removed

the part with a knife before finishing with a file and glass paper: stage one

took an evening to complete. This may be a relative small model with a limited

number of parts but is certainly not a quick build. The parts are well moulded

for a limited run kit, and except for the engine the white metal parts are a

good idea as they add strength to the model and provide better pieces to work

with. The engine is a bit crude but as it is mostly concealed this can be

overlooked by all except the most fastidious modeller. There is a problem with

the wings and tail surfaces however as they are much too thick, especially the

trailing edges, but unless you are prepared to spend another evening sanding

them down this problem is best treated by sanding some of the plastic and

leaving the rest, as much for strength as any other reason. I did replace the

vertical tail surfaces as these were too thick and not really of the correct

shape.

| CONSTRUCTION |

Before assembling the

fuselage the interior needs to be painted. The front end forward of the pilots

cockpit was bare metal, but the bulkheads were plywood, The seats (which are a

little crude but with cleaning up and thinning, passable), should be attached to

the bulkheads with superglue but only after the bulkheads have been filed to fit

the fuselage interior, and thin card strips used to make a slatted cockpit

floor. A bulkhead from card has to be fitted behind the pilot's seat and between

the engine and front cockpit. The hole under the pilot's cockpit, where the

control column extended below the fuselage floor needs to be cleaned up too. The

biggest problem was the engine which does not fit the hole in the front fuselage

as the latter is too small. This can only be resolved by extending the hole to

just in front of the observer's cockpit and putting a piece of 10thou card under

the engine platform to lift it a little. Joining all of the interior parts to

one fuselage half is tricky as the bulkheads have to be filed to make them fit

properly, the engine has to be centred properly on its little platform and the

engine intake on the left side have to fit into the recesses in the fuselage. In

addition superglue is needed to hold the white metal parts and plastic cement

the plastic additions, so a lot of juggling is required. Once you have got the

interior parts to go into the correct places the fuselage halves can be joined

and when dry the joint filled and cleaned up. I replaced the vertical tail

surfaces with pieces cut from 20thou plastic card, using a scale plan to get the

correct shape. Do not cement the upper surface until you have painted the cross

as this is very small and the rudder is inaccessible once it is fitted. The

horizontal tail surface recess will need to be opened with a knife and file: do

this carefully to keep the opening symmetrical and so that you do not

remove too

much plastic. When you are satisfied with the fit thin down the trailing edge

and then glue into place and when dry fill and sand down the joints. Drill a

hole in the nose to take a pin on the propellor later.

remove too

much plastic. When you are satisfied with the fit thin down the trailing edge

and then glue into place and when dry fill and sand down the joints. Drill a

hole in the nose to take a pin on the propellor later.

The wing trailing edges need thinning - it is up to you how much plastic you remove but the more the better really. Now drill the holes on the undersides of the wings to take the spar support struts, and drill two holes right through the wings for the king posts. Also drill a hole in the end of each wing for the spar extensions and in the horizontal tail surfaces at the same time. I decided to strengthen the wing joints by adding a thin piece of wire which acted as a spar between the cockpits. Accurately measure the wings and drill a shallow horizontal hole in each, making sure that they are directly opposite each other. The hold the wing to the fuselage and mark on the positions of the holes on the fuselage sides before drilling the holes. Insert a short piece of wire into the fuselage and superglue into place. Trim the ends of the wire if they are too long before putting superglue on one end. Take a wing and add a small amount of cement to the edge which will attach to the fuselage side and push the wing on to the end of the wire and against the fuselage side. Get everything properly aligned and support this wing while it dries out thoroughly. Repeat this operation on the other wing. When the wings are dry fill the joints and rub down.

| COLORS & MARKINGS |

Now is the time to paint

the model, especially if you want to put on markings as the wings will not be

accessible when the underwing spar is added. These aircraft were overall clear

doped linen with bare metal panels around the nose and upper fuselage between

the cockpits. I used a mixture of white with a little Humbrol 81 (ratio of about

3:1 but the exact proportions are not terribly important). A small amount of

light grey also helps to give a slightly darker tone of dirty linen. The metal

was Humbrol silver with medium grey mixed in - about 3 parts silver to one part

grey. The radiators were brass, tyres light grey (or off-white on some early

machines), undercarriage legs, forks and axle black, and the remaining struts

and pylons brown. I hand painted the crosses as I did not have a suitable source

for them. I chose the simpler early straight sided crosses - painting crosses

with curved sides was a step too far! Measure carefully where the centre of the

cross should be and mark it with the point of a divider. Now draw a cross the

arms of which are the exact size of the finished cross, centred on the hole from

the divider. At the end of each of the four lines draw a second line at 90

degrees which is the exact length of the outer edge of the cross:

make sure

that the original cross arm bisects the new line exactly. When this has been

done on each of the ends of the original cross, the sides of the cross arms can

be drawn from the ends of short outer lines through the hole at the centre. This

will give you four equal sided triangles with their apexes at the centre. I

scribed these lines with the point of a divider and then painted the black with

a fine paintbrush and slightly thinned paint. The cross on the upper rudder was

the most difficult because it was so small but it can be done if it is not

attached to the model. If you choose to model a later machine with the white

squares and Maltese cross form I suggest that you try to print your own or use

the transfers from the Revell Fokker E 111 for the wings. Alternatively you

could use the Pegasus German WW1 crosses sheet if you can find a set on the

internet. Strictly the crosses form the Revell EIII are fractionally too small

but only the purist would notice. However you will need a cross and white square

on both the upper and lower rudders and I do not know where such small crosses

can be obtained, apart from home-made sources. Note too that if you present your

model with crosses on white squares then it will not be an Etrich taube but one

from another manufacturer and some minor alterations to the kit will have to be

made which are not covered here.

make sure

that the original cross arm bisects the new line exactly. When this has been

done on each of the ends of the original cross, the sides of the cross arms can

be drawn from the ends of short outer lines through the hole at the centre. This

will give you four equal sided triangles with their apexes at the centre. I

scribed these lines with the point of a divider and then painted the black with

a fine paintbrush and slightly thinned paint. The cross on the upper rudder was

the most difficult because it was so small but it can be done if it is not

attached to the model. If you choose to model a later machine with the white

squares and Maltese cross form I suggest that you try to print your own or use

the transfers from the Revell Fokker E 111 for the wings. Alternatively you

could use the Pegasus German WW1 crosses sheet if you can find a set on the

internet. Strictly the crosses form the Revell EIII are fractionally too small

but only the purist would notice. However you will need a cross and white square

on both the upper and lower rudders and I do not know where such small crosses

can be obtained, apart from home-made sources. Note too that if you present your

model with crosses on white squares then it will not be an Etrich taube but one

from another manufacturer and some minor alterations to the kit will have to be

made which are not covered here.

| MORE CONSTRUCTION |

When you have completed

the painting cut the under-wing spars from the strut material and the support

struts and king-posts from the rod, and fix the underwing spars into place. I

did this by measuring the king post accurately and inserting as one piece into

the wing. Then I cut the spar and glued it to the end of the king post and the

fuselage and finished by measuring the support struts with dividers and cutting

them to fit before gluing into place. This exercise is also tricky and should be

done carefully. The radiators can be fixed to the fuselage using superglue at

this stage. The undercarriage is next and the diagram in the instruction sheet

is misleading. This is a complex structure to describe but it consists of two

forks which hold the axle, two vertical posts in front with a cross-bracing

between them at the bottom, and two arms between the ends of the axle and the

forward posts. Two V struts attach to the fuselage and a joint at the bottom of

the forward vertical posts. Start by opening the arms on the undercarriage forks

until the wheels will fit properly: these are white metal and bend easily. Add

the cross bracing between the arms of the forks of the main undercarriage legs,

using two short lengths of rod supplied in the kit. I replaced the forward white

metal vertical posts with thick plastic rod. Cut an axle and forward cross

bracing member from rod supplied in the kit. Now cement the vertical posts to

the plates on the leading edges of the wings and the V struts (also in white

metal) between the fuselage and the base of the posts. Fix the cross bracing

between the bottoms of the posts and ensure that all is square and allow to dry.

Superglue the main undercarriage legs to the plates on the wing and angle them

back a little so that the small horizontal forks (white metal) can be attached

to the base of the vertical posts, and glue the base of the forks on to the main

legs. Insert the wheels into the forks and finally glue the axle into place and

allow the whole assembly to dry out thoroughly. This is another tricky set of

operations but if they are tackled systematically and carefully a neat job can

be achieved and it is stronger than it looks. Finally add the tail skid (also

white metal), the spar extensions and exhaust pipes (cut from rod supplied in

the kit), and lower fuselage pylon and nose bracing struts (white metal). Drill

a hole in the rear of the propellor and glue a short piece of rod into the rear

to make a pin. Leave the upper pylon and the upper rudder post until later. I

now painted the wooden parts of the undercarriage assembly and the spar

extensions, pylon, skid and propellor. (I had painted the undercarriage forks

and wheels prior to assembly).

There is a great deal of

rigging on this model: I have made several pushers and even the Sopwith Gunbus

did not have as many wires as this one! However the pattern is repetitive so it

is not as difficult as

it may

first appear. Before you start decide whether you wish to put in in all of the

wires or only representative ones. Then work methodically on one part of the

model at a time, putting in the least accessible wires first and leaving the

most exposed, (the wing and tail bracing from the spar extensions, and the nose

bracing until last). I also started on the underside and rigged all of this,

leaving the upper fuselage pylon and upper rudder post off because these can be

easily knocked off. (I managed to knock off a tail and wing spar extension too -

great care is needed with this model as it seem to have parts sticking out in

all directions!) I used the following procedure which made sure that I did not

leave out any wires or do too much damage to the completed parts:

it may

first appear. Before you start decide whether you wish to put in in all of the

wires or only representative ones. Then work methodically on one part of the

model at a time, putting in the least accessible wires first and leaving the

most exposed, (the wing and tail bracing from the spar extensions, and the nose

bracing until last). I also started on the underside and rigged all of this,

leaving the upper fuselage pylon and upper rudder post off because these can be

easily knocked off. (I managed to knock off a tail and wing spar extension too -

great care is needed with this model as it seem to have parts sticking out in

all directions!) I used the following procedure which made sure that I did not

leave out any wires or do too much damage to the completed parts:

1. Mark on to the wing and tail surfaces the points

where the ends of a wire need to be attached and make a tiny hole with the sharp

point of a set of dividers. I use copper wire and superglue: a small drop of

glue on the end of the wire will attach the wire to the hole.

2. Rig the underwing spars - just the vertical wires;

3. rig the underwing spar supports from the wing

leading edge and to the rear spar;

4. put on the aileron control wires from the king

posts. Do this by gluing the centre wire first followed by the two inner and

then the two outer wires (see photos);

5. now the underwing spar extension wires;

6. tail unit control wires from the rudder post.

Start by accurately measuring the length of the two inner wires using dividers.

Glue the ends to the holes in the tail surface and bring the forward ends to the

point of a v and glue together. Cut a piece of wire approx. 5mm long and glue

one end to the rudder post and one to the apex of the v - hold it in place while

it dries. Now add the outer control wires one at a time working outwards and

ensuring that each wire attaches to the same place at the apex of the v. Tiny

drops of superglue on the ends of the wires are enough to hold them in place;

7. complete the remainder of the underside rigging

and control wires to the under fuselage pylon from the nose, tail and wings;

8. carefully turn the model over and glue the upper

fuselage pylon and upper rudder post into place. Repair any broken spar

extensions!

. start

on one wing and rig the bracing from the pylon to the rear wing spar, starting

with the shortest wire, and put in each wire until you reach the king post and

then rig the leading edge of the wing, also starting with the shortest wire;

. start

on one wing and rig the bracing from the pylon to the rear wing spar, starting

with the shortest wire, and put in each wire until you reach the king post and

then rig the leading edge of the wing, also starting with the shortest wire;

10. then rig the control wires from the king post,

and the bracing wires to the wing edges from the king post;

11. repeat the above for the other wing and put on

the forward bracing from the pylon to the nose;

12. rig the upper tail surface starting with the

control wires from the rudder post, then the bracing wires from the fin to the

horizontal surfaces, control wires from fuselage spine to rudder and bracing

from the pylon to the base of the spar extensions;

13. starting at the tail work your way around the

model adding all of the remaining spar extension bracing wires to the tail,

fuselage and wings. Last of all add the bracing from the base of the

undercarriage vertical posts to the nose.

This may not make much sense at first reading, but if

you are attempting to rig this model, things will become obvious as you proceed.

To complete the model

cement the propeller to the nose and touch in any paintwork as necessary, making

sure that you do not knock off or damage any wires in the process!

| CONCLUSIONS |

This was not an easy

model to build and I would not recommend it unless you have experience with

conventional kits and perhaps some experience with detailing, conversions or

scratch building as it is not one for those who are faint heated or want a quick

finish. Although it looks simple it took me nearly two months to complete, as

long in fact as a pusher conversion. You do not have to complete all of the rigg ing

of course - add what you want to, but the effort was worthwhile in my opinion

even though it took a long time. In fact it was actually easier than some

pushers and other biplanes because all of the points of attachment are easily

accessible and most of the operations are repetitive and straightforward. Only

the control wires gave any real challenge which was overcome by a little care, a

lot of patience, accurate measurement from the model, some bad language (but

less than you might expect), and an eye loupe (magnifier) on my spectacles. In

terms of accuracy and time spent making it I think that this offers good value

for money. In my opinion this is a much more interesting and eye-catching

subject than the standard WW1 or WW2 subjects, or even post WW2 models that sit

in so many cabinets, striking though many of those models are. I like a model

that is challenging and different - this was a real challenge and it is very

different.

ing

of course - add what you want to, but the effort was worthwhile in my opinion

even though it took a long time. In fact it was actually easier than some

pushers and other biplanes because all of the points of attachment are easily

accessible and most of the operations are repetitive and straightforward. Only

the control wires gave any real challenge which was overcome by a little care, a

lot of patience, accurate measurement from the model, some bad language (but

less than you might expect), and an eye loupe (magnifier) on my spectacles. In

terms of accuracy and time spent making it I think that this offers good value

for money. In my opinion this is a much more interesting and eye-catching

subject than the standard WW1 or WW2 subjects, or even post WW2 models that sit

in so many cabinets, striking though many of those models are. I like a model

that is challenging and different - this was a real challenge and it is very

different.

September 2014

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.