The Caproni Ca 5 was designed in 1917 as a replacement for the earlier

successful Ca 3 series of aircraft.The Ca 5 was slightly larger than its

predecessor and the early versions were powered by Fiat A 12 engines

developing between 200 and 300 horse power. Radiators were fitted in front

of the engine on the booms, but in the nose of the fuselage for the middle

engine which was in a pusher configuration. Three engines were used because

of the nature of the terrain (most of the bombing raids had to pass over the

Alps) and distances involved: a third engine gave both increased power and a

better chance for the crew to return in the event of an engine malfunction.

Later variants of the basic design were powered by Fiat, Isotta or Liberty

engines which meant slight redesign of the nacelles, and in the case of the

Liberty engin ed variants, the nose radiator was replaced by one mounted in

front of the engine at the rear of the fuselage. Defensive armament

consisted of a machine gun in the nose and one mounted on a platform above

the engine in the fuselage and behind the top wing. Most of these machines

were operated by the italian Air Force but a small number was also supplied

to the American Air Service where they were deployed over the Western Front.

Plans to build 1500 machines of this type in the US were cancelled when

peace resumed in 1918. The type was used with some success as a bomber from

late 1917 and through 1918 and after the war it continued in service with

the Italian air force until the mid 1920's. At least one machine was fitted

with floats and Liberty engines but this was not delivered until 1919 and so

did not see wartime service. Some machines were converted to air ambulances

in the post war period - they could carry two stretcher cases, one in each

nacelle behind the engines, and up to 4 sitting cases in the fuselage: the

fuel tanks were reduced in size to accommodate the seats. In terms of

overall performance the design was a little disappointing as it suffered

from constant engine problems. The fuselage engine was difficult to cool,

and all of the engines tended to have a low reliability because of the poor

quality control in the engine factories in Italy. Production was also

hampered by the lack of skilled workers to make these complex aircraft in

Italy at that time, but the type earned respect from its crews for its

rugged qualities and powers of endurance which made them well suited to the

conditions in which they had to operate.

ed variants, the nose radiator was replaced by one mounted in

front of the engine at the rear of the fuselage. Defensive armament

consisted of a machine gun in the nose and one mounted on a platform above

the engine in the fuselage and behind the top wing. Most of these machines

were operated by the italian Air Force but a small number was also supplied

to the American Air Service where they were deployed over the Western Front.

Plans to build 1500 machines of this type in the US were cancelled when

peace resumed in 1918. The type was used with some success as a bomber from

late 1917 and through 1918 and after the war it continued in service with

the Italian air force until the mid 1920's. At least one machine was fitted

with floats and Liberty engines but this was not delivered until 1919 and so

did not see wartime service. Some machines were converted to air ambulances

in the post war period - they could carry two stretcher cases, one in each

nacelle behind the engines, and up to 4 sitting cases in the fuselage: the

fuel tanks were reduced in size to accommodate the seats. In terms of

overall performance the design was a little disappointing as it suffered

from constant engine problems. The fuselage engine was difficult to cool,

and all of the engines tended to have a low reliability because of the poor

quality control in the engine factories in Italy. Production was also

hampered by the lack of skilled workers to make these complex aircraft in

Italy at that time, but the type earned respect from its crews for its

rugged qualities and powers of endurance which made them well suited to the

conditions in which they had to operate.

The use of three engines seemed to have established a trend for larger

Italian and some German interwar designs as a large number of trimotors were

built and used in this period and during WW2, making use of the advantages

of this particular engine layout.

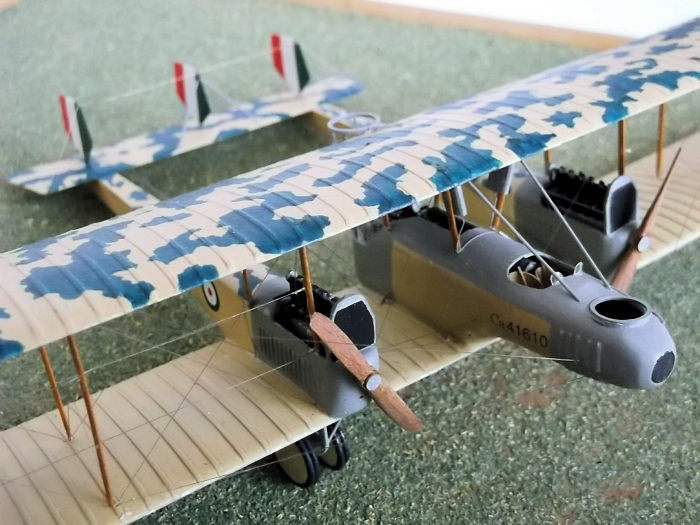

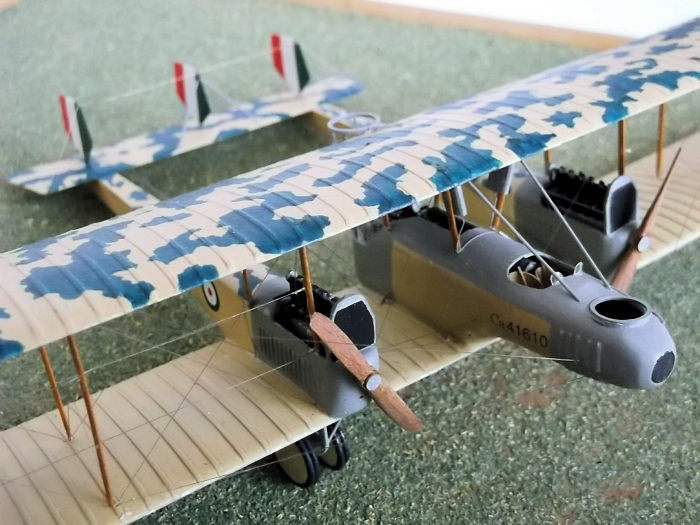

The engines were made from 2 strips of 60 thou card sandwiching a strip

of 20 thou card. This was then filed and sanded to shape. The cylinders were

from 100 thou rod. Only the engine in the fuselage nacelle needs the magneto

because these cannot be seen on the engines in the booms. The cam shaft was

from 20 thou rod and the valve springs from short pieces of rod. The

carburettor was from card and rod. The exhausts were 25 thou rod cut to

length. The radiators were cut and shaped from 40 you card with the front

and rear scribed to represent the radiator grilles. Remember in this scale

much fine detail cannot be seen without a hand lens, so that the modeller

needs to give an impression of what things look like rather than trying to

replicate every fine detail.

The engines were made from 2 strips of 60 thou card sandwiching a strip

of 20 thou card. This was then filed and sanded to shape. The cylinders were

from 100 thou rod. Only the engine in the fuselage nacelle needs the magneto

because these cannot be seen on the engines in the booms. The cam shaft was

from 20 thou rod and the valve springs from short pieces of rod. The

carburettor was from card and rod. The exhausts were 25 thou rod cut to

length. The radiators were cut and shaped from 40 you card with the front

and rear scribed to represent the radiator grilles. Remember in this scale

much fine detail cannot be seen without a hand lens, so that the modeller

needs to give an impression of what things look like rather than trying to

replicate every fine detail.

The wings were made by laminating a strip of 30 thou card which had been

bent in boiling water with a strip of 20 thou card laid over the top. The 30

thou strip was wide enough to extend to the rear spar, and then a strip of

20 thou card and 10 thou card was laid along the trailing edge of the 30

thou card. The edges of the card on the undersides was then sanded until a

smooth aerofoil section was achieved and the trailing edge was as thin as

possible. The leading edge was rounded off to give the correct profile. Ribs

were 10 x 20 thou strip glued into place and then sanded to shape. Holes

were drilled in the wings for the struts, and undercarriage and wing skids

under the lower wing.

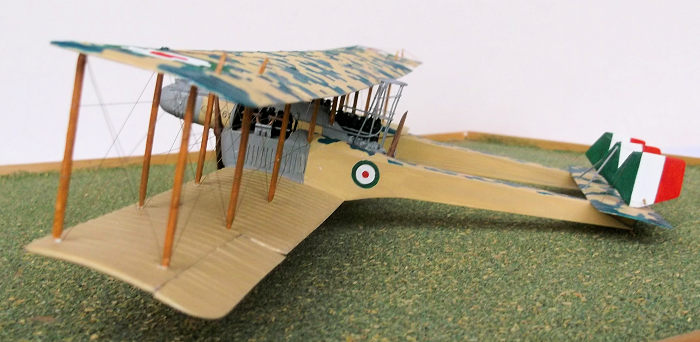

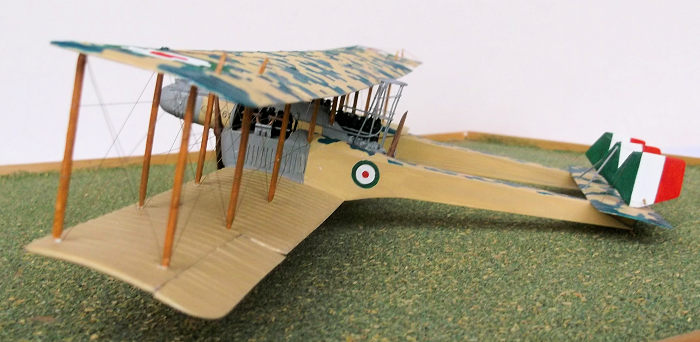

The booms were simple box structures with sides, top and bottom of 20

thou card. Strips were placed on the inside edges of the sides to provide

support for the corners and help to get them square. Formers were also made

from scrap card, three per boom, and the rear ends from 20 thou card. The

curved lower surface of the booms was achieved by sliding the card between

tweezers 3 - 5 times. The tops of the booms were moulded in the normal way

from 30 thou card with filler used to fair in the rear ends. Two 30 x 40

thou strips were glued on to the top of the lower wing to hold the booms in

place. The louvres on the sides of the booms were made from 10 x 20 thou

strip cut to length and glued in place and when dry they were filed and

sanded to shape.

The booms were simple box structures with sides, top and bottom of 20

thou card. Strips were placed on the inside edges of the sides to provide

support for the corners and help to get them square. Formers were also made

from scrap card, three per boom, and the rear ends from 20 thou card. The

curved lower surface of the booms was achieved by sliding the card between

tweezers 3 - 5 times. The tops of the booms were moulded in the normal way

from 30 thou card with filler used to fair in the rear ends. Two 30 x 40

thou strips were glued on to the top of the lower wing to hold the booms in

place. The louvres on the sides of the booms were made from 10 x 20 thou

strip cut to length and glued in place and when dry they were filed and

sanded to shape.

The nacelle was moulded from 30 thou card. The interior consisted of a

floor which I assume was an open frame so I used thin strip to make one each

for the three cockpits, control panel with two sets of throttles, instrument

panel, seats for the pilots and front and rear gunners, and control wheels.

Fuel tanks were made from card bent to shape and the ends were simple

blanks.Some interior framing was added from thin strip.The gun rings were

made from 20 thou card which had been scribed with a pair of dividers. The

radiator louvres on the nose were made from 10 x 20 thou strip as per the

booms. The fronts of the nacelles were moulded from 30 thou card which were

glued into place after the engines had been fitted into the nacelles.

The tail surfaces were cut from 20 thou card and sanded to section. The

ribs were from 10 x 20 thou strip.

Wheels were made from discs of 60 thou card.. First I scribed a circle of

the correct diameter into the card with a pair of dividers. Then the card

was cut into squares and finally rounded to shape with a file and sand paper

using the scribed circles as a guide. One side of each disc was then filed

to give a curved face. The tyres were made by bending 60 thou rod around a

paintbrush handle and immersing it in boiling water for 10 seconds. I

removed the rod and let it cool while still holding it under tension while

it did so. Lengths of rod could then be cut to fit around each disc. By

making the rod spiral smaller than the discs the rod sat tightly around the

edges of the discs and could be held in place with liquid glue.

The struts were cut from 30 x 60 thou strip and filed to shape. The main

wing struts needed holes drilled into them to take the lateral bracing wires

later. The undercarriage was made from strip for the legs and 30 thou card

for the axle supports between the vertical legs. The bracing booms on the

nose and rudder struts were 20 thou rod.

The struts were cut from 30 x 60 thou strip and filed to shape. The main

wing struts needed holes drilled into them to take the lateral bracing wires

later. The undercarriage was made from strip for the legs and 30 thou card

for the axle supports between the vertical legs. The bracing booms on the

nose and rudder struts were 20 thou rod.

The propellors were carved from some thick wood laminate - I am not sure

which wood but your local DIY store will have a selection. The bosses were

from 20 thou card.

Having made all of the major components I could start assembly as per

any kit. The booms and fuselage nacelles were assembled in the usual manner

and the fuselage nacelle glued to the lower wing first. This needed careful

alignment and a jig to support it while it dried out so they the horizontal

centre line was at the correct angle to the wing surface. When this was

complete one boom was added at a time to the lower wing, again using the

drawing to help get the correct alignment. The engines were put into the

booms using scrap plastic to provide the necessary supports. The moulded

nacelle fronts and radiators completed the booms. The main struts were glued

into the inside edges of the nacelles and allowed to set hard. The

horizontal tail surface was glued to the rear of the booms.

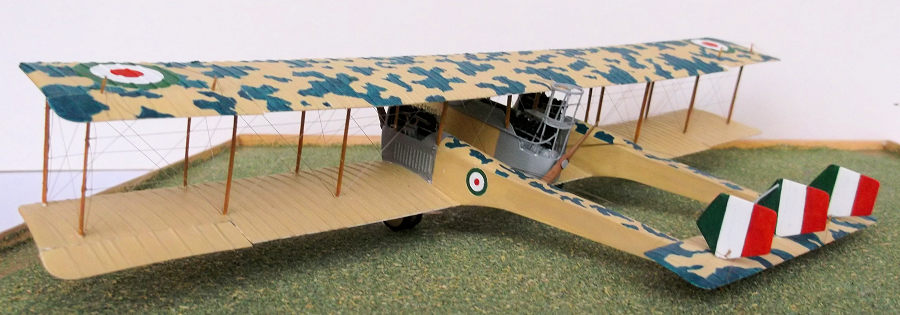

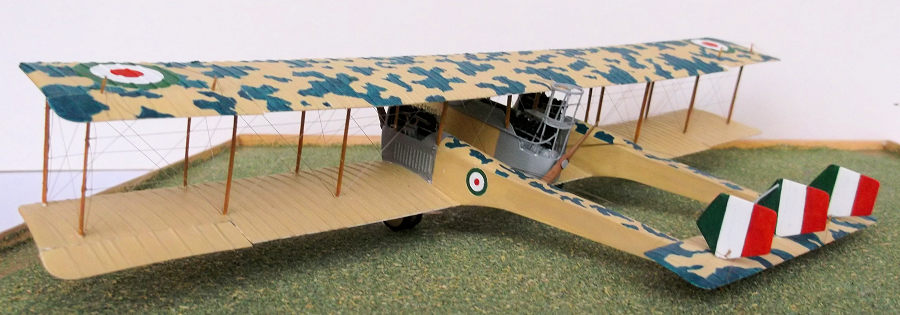

The wings, booms, tail, struts and wheels were now painted. Markings were

hand painted but the serial was printed on to transfer paper and applied

when the painting was complete.

The wings, booms, tail, struts and wheels were now painted. Markings were

hand painted but the serial was printed on to transfer paper and applied

when the painting was complete.

Now the outer struts could be cemented to the lower wing and while these

were still flexible the top wing could be lowered on to the struts and held

in place with support while it dried out. This structure was not very strong

but it allowed the addition of the remainder of the wing and nacelle struts

and cabanas to be carefully inserted. The small radiators on the forward

cabane struts were made from 30 thou card and the pipes from thin copper

wire. The pipes on the fuselage sides were 30 thou rod. Next the ailerons,

undercarriage legs and wing skids were fixed into place. The model was

rigged using dark monofilament thread. Finally the rear gun position was

made and glued into place, followed by the rudders which were held with thin

pins of 5 amp fuse wire, the propellors, (also held with wire), and the

wheels which have wire axles. The tail was rigged and the front bracing

struts added. The last task was to add the drag wires from the nose to the

leading edges of the wings.

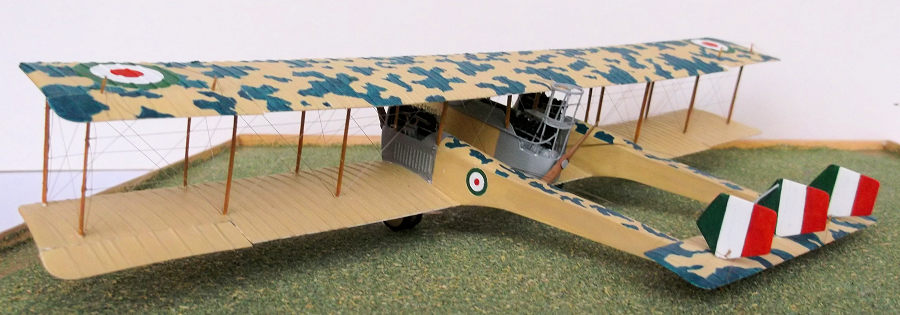

There are occasions when I wish to add a model to my collection which is not

available as a kit in any form. The Caproni Ca5 is an example of this. It

was not a particularly important or successful aeroplane, but I found it to

be of interest because of the exposed rear gunner position and I wanted to

see if I could replicate that. It is also a multi-bay biplane which offers

distinct challengers to the modeller. The camouflage pattern is also unusual

and that too attracted my attention. Unfortunately there is little

information available on this type published in English and researching the

type took a long time. From a modelling view there were many processes which

had to be used, so it was a good type to practice or refresh a number of

different skills and made for an interesting project.

Stephen Foster

12 October 2020

Copyright ModelingMadness.com

If you would like your product reviewed fairly and fairly quickly, please

contact

the editor

or see other details in the

Note to

Contributors.

Back to the Main Page

Back to the Review

Index Page

Back to the Previews Index Page

ed variants, the nose radiator was replaced by one mounted in

front of the engine at the rear of the fuselage. Defensive armament

consisted of a machine gun in the nose and one mounted on a platform above

the engine in the fuselage and behind the top wing. Most of these machines

were operated by the italian Air Force but a small number was also supplied

to the American Air Service where they were deployed over the Western Front.

Plans to build 1500 machines of this type in the US were cancelled when

peace resumed in 1918. The type was used with some success as a bomber from

late 1917 and through 1918 and after the war it continued in service with

the Italian air force until the mid 1920's. At least one machine was fitted

with floats and Liberty engines but this was not delivered until 1919 and so

did not see wartime service. Some machines were converted to air ambulances

in the post war period - they could carry two stretcher cases, one in each

nacelle behind the engines, and up to 4 sitting cases in the fuselage: the

fuel tanks were reduced in size to accommodate the seats. In terms of

overall performance the design was a little disappointing as it suffered

from constant engine problems. The fuselage engine was difficult to cool,

and all of the engines tended to have a low reliability because of the poor

quality control in the engine factories in Italy. Production was also

hampered by the lack of skilled workers to make these complex aircraft in

Italy at that time, but the type earned respect from its crews for its

rugged qualities and powers of endurance which made them well suited to the

conditions in which they had to operate.

ed variants, the nose radiator was replaced by one mounted in

front of the engine at the rear of the fuselage. Defensive armament

consisted of a machine gun in the nose and one mounted on a platform above

the engine in the fuselage and behind the top wing. Most of these machines

were operated by the italian Air Force but a small number was also supplied

to the American Air Service where they were deployed over the Western Front.

Plans to build 1500 machines of this type in the US were cancelled when

peace resumed in 1918. The type was used with some success as a bomber from

late 1917 and through 1918 and after the war it continued in service with

the Italian air force until the mid 1920's. At least one machine was fitted

with floats and Liberty engines but this was not delivered until 1919 and so

did not see wartime service. Some machines were converted to air ambulances

in the post war period - they could carry two stretcher cases, one in each

nacelle behind the engines, and up to 4 sitting cases in the fuselage: the

fuel tanks were reduced in size to accommodate the seats. In terms of

overall performance the design was a little disappointing as it suffered

from constant engine problems. The fuselage engine was difficult to cool,

and all of the engines tended to have a low reliability because of the poor

quality control in the engine factories in Italy. Production was also

hampered by the lack of skilled workers to make these complex aircraft in

Italy at that time, but the type earned respect from its crews for its

rugged qualities and powers of endurance which made them well suited to the

conditions in which they had to operate. The engines were made from 2 strips of 60 thou card sandwiching a strip

of 20 thou card. This was then filed and sanded to shape. The cylinders were

from 100 thou rod. Only the engine in the fuselage nacelle needs the magneto

because these cannot be seen on the engines in the booms. The cam shaft was

from 20 thou rod and the valve springs from short pieces of rod. The

carburettor was from card and rod. The exhausts were 25 thou rod cut to

length. The radiators were cut and shaped from 40 you card with the front

and rear scribed to represent the radiator grilles. Remember in this scale

much fine detail cannot be seen without a hand lens, so that the modeller

needs to give an impression of what things look like rather than trying to

replicate every fine detail.

The engines were made from 2 strips of 60 thou card sandwiching a strip

of 20 thou card. This was then filed and sanded to shape. The cylinders were

from 100 thou rod. Only the engine in the fuselage nacelle needs the magneto

because these cannot be seen on the engines in the booms. The cam shaft was

from 20 thou rod and the valve springs from short pieces of rod. The

carburettor was from card and rod. The exhausts were 25 thou rod cut to

length. The radiators were cut and shaped from 40 you card with the front

and rear scribed to represent the radiator grilles. Remember in this scale

much fine detail cannot be seen without a hand lens, so that the modeller

needs to give an impression of what things look like rather than trying to

replicate every fine detail. The booms were simple box structures with sides, top and bottom of 20

thou card. Strips were placed on the inside edges of the sides to provide

support for the corners and help to get them square. Formers were also made

from scrap card, three per boom, and the rear ends from 20 thou card. The

curved lower surface of the booms was achieved by sliding the card between

tweezers 3 - 5 times. The tops of the booms were moulded in the normal way

from 30 thou card with filler used to fair in the rear ends. Two 30 x 40

thou strips were glued on to the top of the lower wing to hold the booms in

place. The louvres on the sides of the booms were made from 10 x 20 thou

strip cut to length and glued in place and when dry they were filed and

sanded to shape.

The booms were simple box structures with sides, top and bottom of 20

thou card. Strips were placed on the inside edges of the sides to provide

support for the corners and help to get them square. Formers were also made

from scrap card, three per boom, and the rear ends from 20 thou card. The

curved lower surface of the booms was achieved by sliding the card between

tweezers 3 - 5 times. The tops of the booms were moulded in the normal way

from 30 thou card with filler used to fair in the rear ends. Two 30 x 40

thou strips were glued on to the top of the lower wing to hold the booms in

place. The louvres on the sides of the booms were made from 10 x 20 thou

strip cut to length and glued in place and when dry they were filed and

sanded to shape. The struts were cut from 30 x 60 thou strip and filed to shape. The main

wing struts needed holes drilled into them to take the lateral bracing wires

later. The undercarriage was made from strip for the legs and 30 thou card

for the axle supports between the vertical legs. The bracing booms on the

nose and rudder struts were 20 thou rod.

The struts were cut from 30 x 60 thou strip and filed to shape. The main

wing struts needed holes drilled into them to take the lateral bracing wires

later. The undercarriage was made from strip for the legs and 30 thou card

for the axle supports between the vertical legs. The bracing booms on the

nose and rudder struts were 20 thou rod. The wings, booms, tail, struts and wheels were now painted. Markings were

hand painted but the serial was printed on to transfer paper and applied

when the painting was complete.

The wings, booms, tail, struts and wheels were now painted. Markings were

hand painted but the serial was printed on to transfer paper and applied

when the painting was complete.