Blue Max 1/48 Sopwith Snipe

|

KIT: |

Blue Max 1/48 Sopwith Snipe |

|

KIT # |

113 |

|

PRICE: |

$42.98 |

|

DECALS: |

Two aircraft |

|

REVIEW & |

|

|

NOTES: |

Limited Run Injection Molded |

|

HISTORY |

Tom Cleaver has already written an excellent history and description of the kit that can be found on this site at reviews/ww1/cleaversnipe.htm. I agree with him completely and could not add anything new so I wonít bore the reader with a rehash of those segments of the review.

|

CONSTRUCTION |

The first job up was to

separate and clean up the plastic and metal parts. Care must be taken when

removing the plastic parts, as the pour stubs on the sprue are very thick and

pass into the part itself. I used a razor saw to cut off all parts to prevent

damage to the adjacent surfaces. This task also included filing off of several

molding channels and general flash clean up. It is critical when building a

limited run kit, that extensive dry fitting and filing be accomplished prior to

assembly so I assembled the major parts with masking tape to judge fit and

shaped the parts where needed. Virtually every part needed some minor

filing/sanding but in most instances this was no more than a few swipes of a

sanding stick. However, major thinning was required of the fuselage sidewalls as

they were much too thick and the interior would not fit. After all the major

sanding/filing work was done, all parts were given a quick bath in warm soapy

water, given a good rinse, and patted dry.

The first job up was to

separate and clean up the plastic and metal parts. Care must be taken when

removing the plastic parts, as the pour stubs on the sprue are very thick and

pass into the part itself. I used a razor saw to cut off all parts to prevent

damage to the adjacent surfaces. This task also included filing off of several

molding channels and general flash clean up. It is critical when building a

limited run kit, that extensive dry fitting and filing be accomplished prior to

assembly so I assembled the major parts with masking tape to judge fit and

shaped the parts where needed. Virtually every part needed some minor

filing/sanding but in most instances this was no more than a few swipes of a

sanding stick. However, major thinning was required of the fuselage sidewalls as

they were much too thick and the interior would not fit. After all the major

sanding/filing work was done, all parts were given a quick bath in warm soapy

water, given a good rinse, and patted dry.

I then pre-painted all the parts as indicated in the instructions. Assembly of the fuselage components was accomplished using super-thin superglue and care must be taken to properly align the white metal stringers, floor, and bulkhead inside the fuselage. I had a devil of a time getting these items in place, as the fit was very tight (I didnít remove enough from the fuselage sidewalls even though I reduced the thickness by over half!). After many dry fit tries, in which I had to seriously file off the sides of the bulkhead and floor (thank goodness for motor tools!) I finally got everything in place. Cockpit details are a little on the sparse side, however it is adequate and the addition of the Copper States Model (CSM) detail set really adds a lot of detail (most of which unfortunately canít even be seen!).

As with most Sopwith aircraft, the Snipe featured an opening in the rear for the tail plane adjustment mechanism and rudder kingpost. This detail was molded in on the surface, but to accurately portray this distinctive trait, I cut off the aft portion of the fuselage and rebuilt the opening using the cut off pieces and some spare styrene strip. I then glued together the fuselage halves and surprisingly, only a little putty was needed as fit was quite good.

The forward fuselage

deck presented another problem in that it is a hair too wide and tall. Some

careful sanding remedied this being careful to preserve the curved appearance of

the fuselage side. I also sanded off the various detail pieces and replaced them

with the CSM P/E, but this step can be considered unnecessary, as the molded in

detail is fine. I mounted the instrument panel (which also serves as the base

for the guns) to the underside of this piece after carefully sanding the bottom

into the correct profile to allow the guns to lay flat. I then modified the kit

guns with the CSM detail pieces. Generally, I am less than enthusiastic about

P/E parts, but the place where P/E really shines is in machine guns and the CSM

pieces are superb. After drilling out the gun barrels and assembling all the P/E

pieces, the Vickers were painted Metalizer Gun Metal and dry brushed with

Floquil Gun Metal to bring out all the detail. Too bad the majority of the guns

are hidden within the fuselage! I then installed the guns in place with

superglue and used liquid glue to cement the fuselage deck and firewall in

place.

The forward fuselage

deck presented another problem in that it is a hair too wide and tall. Some

careful sanding remedied this being careful to preserve the curved appearance of

the fuselage side. I also sanded off the various detail pieces and replaced them

with the CSM P/E, but this step can be considered unnecessary, as the molded in

detail is fine. I mounted the instrument panel (which also serves as the base

for the guns) to the underside of this piece after carefully sanding the bottom

into the correct profile to allow the guns to lay flat. I then modified the kit

guns with the CSM detail pieces. Generally, I am less than enthusiastic about

P/E parts, but the place where P/E really shines is in machine guns and the CSM

pieces are superb. After drilling out the gun barrels and assembling all the P/E

pieces, the Vickers were painted Metalizer Gun Metal and dry brushed with

Floquil Gun Metal to bring out all the detail. Too bad the majority of the guns

are hidden within the fuselage! I then installed the guns in place with

superglue and used liquid glue to cement the fuselage deck and firewall in

place.

I then made a critical mistake when I mounted the horizontal stabilizer. When I rebuilt the aft end opening, I did not take into account that the stabilizer does not lay flat along the entire fuselage and actually a small gap occurs between the stabilizer and fuselage along the aft end, much like the tail plane. I glued it in place flat with the fuselage, which for some stupid reason I did not notice until much too late to fix; this did not allow the stabilizer to lay correctly on the fuselage.

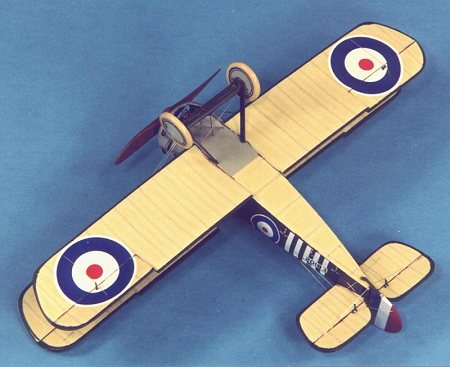

The wings on the Snipe had a significant dihedral, and to accurately assemble the wings in place I used a sophisticated jig (made of two pencils taped to the desk!). I drilled out the small mounting pegs provided and replaced them with brass pins for extra strength. I then glued the lower wings in place (using my sophisticated pencil jig!). After stuffing the cockpit opening with tissue paper it was off to the paint shop.

|

PAINTING & MARKINGS |

The paint scheme is simple, consisting of clear doped linen (CDL) undersurfaces, a light gray (called Battleship Grey) for the metal/plywood surfaces and PC10 doped finish for everything else. I airbrushed Polly Scale Doped Linen on the undersides and after letting dry masked it off and airbrushed Testor Model Master Aircraft Gray. Letting this paint cure overnight since it is a gloss enamel, I then masked it off and airbrushed Xtracolor RFC Green (X22) which I feel is a close color match for the PC10 dope. After the paint scheme cured for a day, I shot a light coat of Future to prepare the surface for decaling.

The decals supplied with

the kit are fairly good. Nice and thin, but an excess of carrier film requires

some delicate trimming. The only problem I had was that the fin stripes were too

narrow and do not correctly cover the rudder. I spliced a spare set of decals

from the decal stash in to cover this obvious mistake. I used MicroSol setting

solution thinned 50% with distilled water and the decals responded very well

melting into the surface (Blue Max does not recommend setting solutions). After

drying overnight, I wiped the decals off with a moist cloth with Pollys Plastic

Prep to remove any residue and after drying I shot a light coat of Future over

the decals to seal them. For weathering, I chose to accentuate the engraved

panel lines and surface detail with a light burnt umber oil wash.

The decals supplied with

the kit are fairly good. Nice and thin, but an excess of carrier film requires

some delicate trimming. The only problem I had was that the fin stripes were too

narrow and do not correctly cover the rudder. I spliced a spare set of decals

from the decal stash in to cover this obvious mistake. I used MicroSol setting

solution thinned 50% with distilled water and the decals responded very well

melting into the surface (Blue Max does not recommend setting solutions). After

drying overnight, I wiped the decals off with a moist cloth with Pollys Plastic

Prep to remove any residue and after drying I shot a light coat of Future over

the decals to seal them. For weathering, I chose to accentuate the engraved

panel lines and surface detail with a light burnt umber oil wash.

I then sealed everything with a light coat of PS Flat Finish to provide a surface for pastel application. I then used pastel pencils to lightly highlight the engraved detail on the wings/tail surfaces, simulate the wood framing showing through the CDL, and also to highlight the delicate rib tapes. I also randomly applied some ground up burnt umber pastels with a soft brush to simulate dirt staining on the lower surfaces. Lastly, I applied a heavy burnt umber oil wash to the wheels and control surface joins.

|

CONSTRUCTION CONTINUES |

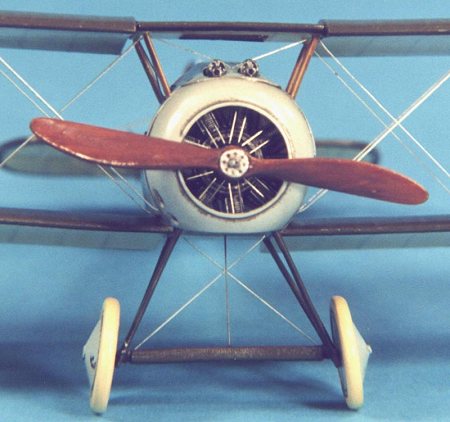

Assembling the Bentley engine is a major job in that the individual cylinders are cast separately and you must fabricate your own pushrods. However, the detail present in this approach provides for one of the best representations of a WWI rotary engine that I have ever seen. After painting the cylinders and crankcase Metalizer Gun Metal, I dry brushed the cooling fins and detail on the crankcase with Metalizer Aluminum. I then painted the intake manifolds rust and applied a heavy wash of Gunze Sangyo Smoke to the entire unit. Assembly of the nine cylinders to the crankcase required some careful work with superglue and the pushrods were cut from .010 stainless steel wire and glued in place with white glue. The completed engine fits nicely into the opening in the firewall to allow it to rotate, but I superglued it in place to prevent damage to the fragile pushrods since they will catch on the cowling wall. The previously painted white metal cowl was superglued into placed and the resulting small gaps were filled with white glue and a wash of burnt umber was applied to help hide the white glue.

Now onto the fun part,

putting on the top wing! This task proved to be quite a challenge, as you must

fabricate the interplane and cabane struts from the strut stock provided. I

carefully placed the top wing in a jig made from Lego pieces and measured out

all the strut lengths with a caliper. The Snipe has distinct shapes to the

forward and aft interplane and cabane struts so I tapered each by filing and dry

fit them in place. After all this work I had a set of struts ready for painting

and used a base coat of Tamiya Dark Yellow and applied a covering coat of

Floquil Brown Mahogany stain. Unfortunately I made a bad decision to not place

pins into the strut ends instead relying on the taper ends to hold the struts in

place into corresponding holes drilled into the wings. Big mistake, as when I

removed the model from the jig I promptly snapped off a few struts. A few

minutes later I pulled a Scott and succeeded in snapping all the remaining

struts off! The tapered struts just do not have the strength to support my

fumbling fingers.

Now onto the fun part,

putting on the top wing! This task proved to be quite a challenge, as you must

fabricate the interplane and cabane struts from the strut stock provided. I

carefully placed the top wing in a jig made from Lego pieces and measured out

all the strut lengths with a caliper. The Snipe has distinct shapes to the

forward and aft interplane and cabane struts so I tapered each by filing and dry

fit them in place. After all this work I had a set of struts ready for painting

and used a base coat of Tamiya Dark Yellow and applied a covering coat of

Floquil Brown Mahogany stain. Unfortunately I made a bad decision to not place

pins into the strut ends instead relying on the taper ends to hold the struts in

place into corresponding holes drilled into the wings. Big mistake, as when I

removed the model from the jig I promptly snapped off a few struts. A few

minutes later I pulled a Scott and succeeded in snapping all the remaining

struts off! The tapered struts just do not have the strength to support my

fumbling fingers.

I may be dumb but Iím not stupid, so I built a new set of struts from some spare strut stock I had. However, this time I installed .020 styrene rod as pins and did not taper the struts to provide a larger bonding area. Of course I had to fill in the previous strut holes, drill them out to accept the .020 pins and repaint portions of the wing. I reassembled my Lego jig and this time installed the struts with liquid cement and after drying, I placed a bead of superglue around each strut for added strength. This approach provided a very sturdy upper wing mount as when I removed it from the jig I could barely flex the upper wing.

Assembly of the landing gear was easy and it was time to put on the tail fin. I installed .020 styrene rod into the base of the tail fin and drilled corresponding holes into the stabilizer. After carefully aligning the tail fin to provide a gap at the aft end I then superglued the rods into place, using the longer rear rod to double as the kingpost. Lastly, I installed the propeller and tailskid and I was almost done with only the rigging to be completed.

I use .006-fishing line painted silver and use a "through-hole" rigging method. I basically drill a hole with an #80 bit (the smallest, about .0135) all the way through the wing at each of my rigging exit points. I try to minimize the number of exit points and run as many lines through them when possible. After securing one end to a partially drilled hole (not all the way through) with superglue, I then run the line out through the exit hole. I weight the end of the line with a pair of hemostats to pull tight by letting it hang down and apply a small drop of superglue to secure it. Let cure for about 30 seconds and then unhook the hemostats and proceed to the next wire. Repeat until done! After letting the entire rigging cure for at least an hour, I then take a brand new Exacto blade and trim flush with the wing surface. I then sand the exit holes flush and apply a spot of touch-up paint to cover. That's it, simple, cheap, and fast. In addition, it also provides a small amount of structural integrity. I can rig a whole airplane in under an hour! Can't do that with wire!

Finally, several coats of Polly S Satin Finish was shot to achieve the semi-gloss finish common to most WWI aircraft.

|

CONCLUSIONS |

This is an excellent model of an important WW I aircraft. Overall the quality and accuracy are exceptional. It was obvious that the scale drawings in the Windsock Datafile were used in the generation of the kit as every detail is exactly reproduced! Due to the limited run nature and its associated fit problems, along with careful work required, I would only recommend this kit to intermediate and advanced level modelers. I also highly recommend the P/E detail sheet produced by CSM (http://www.amug.org/~copperst/main.html) as it provides the seat belts and control horns that are not provided for in the kit and additional items that take the Blue Max kit to a new level of detail, especially with the Vickers machine guns.

|

REFERENCES |

Albatros Productions LTD, Windsock Datafile #46, Sopwith Snipe, $11.00

If you would like your product reviewed fairly and quickly by a site that has over 1,200 visits a day, please contact me or see other details in the Note to Contributors.