Valom 1/72 Fisher P-75A Eagle

| KIT #: | 72010 |

| PRICE: | $ |

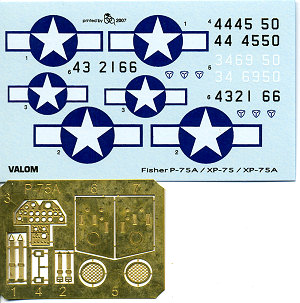

| DECALS: | One option |

| REVIEWER: | Scott Van Aken |

| NOTES: | New Mold kit |

| HISTORY |

In October 1942, the contract for two prototypes, designated XP-75, was signed with the Fisher Body Division of GM. The design concept was to use the outer wing panels from the P-51 Mustang, the tail assembly from the Douglas A-24 (SBD), and the under carriage from the F4U Corsair in a general layout much as in the P-39 Airacobra with the engine located amidships with the propeller driven through an extension shaft. At an early design stage, however, P-40 Warhawk outer wing panels were substituted for the P-51 panels.

In mid 1943, the need for long-range escort fighter became more urgent than fast climbing interceptors so a decision was made to order six more XP-75 airplanes modified for the long-range role. At this time an order for 2,500 production aircraft was also let, but with the stipulation that if the first P-75A was not satisfactory the complete order might be canceled.

Powered by a V-3420-19 twenty-four cylinder engine rated at 2,600 hp driving co-axial contra-rotating propellers, the XP-75 flew for the first time on November 17, 1943. The second XP-75 flew shortly thereafter, and all six long-range XP-75s followed into the test program by the spring of 1944. The test program brought up a number of deficiencies, including miscalculation of the fighterís c.g., engine failure at full rated power, inadequate engine cooling, high aileron forces at high speed, and poor spin characteristics. Re-designs were introduced into the long range XP-75s including a modified tail assembly, new cockpit canopy, and a V-3420-23 engine that corrected most of the problems by the time the first P-75A Eagles entered flight test in September 1944.

By this time, the Army Air Force decided to limit the number of combat aircraft types in production and not enter into large-scale production of new types that might not be available before the war ended. As the P-47D Thunderbolt and P-51D Mustang demonstrated excellent long-range capabilities, the production run of the P-75A Eagle was substantially terminated on October 6, 1944. It was decided to use the five production aircraft completed for experimental work and development of the V-3420 engine. As a result of those events, the P-75A didnít complete formal performance trials due to termination of the production contract.

| THE KIT |

This

is the production version, well, at least as far as it got. To me, this is the

coolest looking of the two so far. The kit consists of a base sprue, one other injected

sprue, one clear, an

etched fret, and a bag of resin bits.

This

is the production version, well, at least as far as it got. To me, this is the

coolest looking of the two so far. The kit consists of a base sprue, one other injected

sprue, one clear, an

etched fret, and a bag of resin bits.

The main sprue is identical to that shown for the

XP-75. For the P-75A the SBD tailplanes and fin/rudder sprue is not included.

What is different, aside from the

instructions is a new injection molded canopy. The smaller fret consists of some interior bits and the

large under fuselage intake. The etched fret is rather minimalist compared to

earlier kits, which is not a bad thing as the goal is to do the kit entirely

from injected plastic. It has belts, rudder pedals and instrument panel. A pair of

radiator grilles and wing inserts are also made of brass. There is a clear

acetate sheet for the instruments (not shown). Resin is used for the prop hub,

wheels and some intake/exhaust stubs. Some of the resin parts will not be used

on this version.

What is different, aside from the

instructions is a new injection molded canopy. The smaller fret consists of some interior bits and the

large under fuselage intake. The etched fret is rather minimalist compared to

earlier kits, which is not a bad thing as the goal is to do the kit entirely

from injected plastic. It has belts, rudder pedals and instrument panel. A pair of

radiator grilles and wing inserts are also made of brass. There is a clear

acetate sheet for the instruments (not shown). Resin is used for the prop hub,

wheels and some intake/exhaust stubs. Some of the resin parts will not be used

on this version.

The overall quality of the Valom kit is quite good.

Like most manufacturers of short run k its,

the molding process seems to improve with each release. I'm quite pleased to see

the etched and resin parts count down, though I can also understand that these

sorts of things are pretty much inevitable for short run kits. I do like how

well molded the canopy is and while I've not fit it, I can anticipate a bit of

trimming needed. The detailing on the airframe is nicely engraved with very well

done rivet detail. Not the sort of huge rivets we see with Trumpeter kits, but

more like the sort of work seen in the plans of older Czech and Soviet paper

bound books and magazines. It is quite well done and believable.

its,

the molding process seems to improve with each release. I'm quite pleased to see

the etched and resin parts count down, though I can also understand that these

sorts of things are pretty much inevitable for short run kits. I do like how

well molded the canopy is and while I've not fit it, I can anticipate a bit of

trimming needed. The detailing on the airframe is nicely engraved with very well

done rivet detail. Not the sort of huge rivets we see with Trumpeter kits, but

more like the sort of work seen in the plans of older Czech and Soviet paper

bound books and magazines. It is quite well done and believable.

Instructions are the typical Valom type with nicely drawn construction drawings and large part and paint information. A large painting and decal placement guide is provided in full color. There is one serial optionson this overall unpainted metal aircraft. The small sheet is well printed and has the insignia and serials for both of the kits, which really makes perfect sense. Actually, that may well be three kits as the decal sheet is marked for an XP-75A as well. It is well printed, though typical of some decal sheets for US planes, has a blue border that is too skinny in relation to the rest of the markings. When they added the 'wings' to the insignia, they also added a blue border to the star area as well and these insignia do not show that. Not a biggie as most of us have extra US insignia, but for completeness, I thought I'd point that out.

As I initially stated, I'm quite pleased to see this kit produced in injected plastic. Resin is nice, but if I had a choice I'd much rather have styrene to work with. I'm sure this will be a huge seller amongst prototype fans. Some of Valom's kits have sold out quite quickly so you need to get yours at the earliest opportunity.

Thanks to Valom for the review kit.

October 2007

If you would like your product reviewed fairly and quickly, please contact me or see other details in the Note to Contributors.