October 12

With a

contest last Saturday, it meant that Friday was spent getting ready for it

and most of today spent recuperating from it! However, I did manage to do a

few things on it late this evening. First, I cut the prop blade/hub bits

from the sprues. I'd already painted the prop blades, but that was sort of

ruined by the need to sand on the tips where the sprue gates were located.

Next I attached them to one half of the hub and glued the other atop it.

Fit isn't very good as I had a gap all around it. That was clamped in place

and when dry, filler placed into the spaces. Now I do realize that much of

this won't be seen once I get the spinner in place, but the flashlight gang

will be able to peer in there and so I wanted to get it smoothed out.

With a

contest last Saturday, it meant that Friday was spent getting ready for it

and most of today spent recuperating from it! However, I did manage to do a

few things on it late this evening. First, I cut the prop blade/hub bits

from the sprues. I'd already painted the prop blades, but that was sort of

ruined by the need to sand on the tips where the sprue gates were located.

Next I attached them to one half of the hub and glued the other atop it.

Fit isn't very good as I had a gap all around it. That was clamped in place

and when dry, filler placed into the spaces. Now I do realize that much of

this won't be seen once I get the spinner in place, but the flashlight gang

will be able to peer in there and so I wanted to get it smoothed out.

The other part of the modeling time was spent on some

controls. For the wing, I superglued the little etched 'hooks' into the

lower half of the wing for each surface. You have to use accelerator on

these or you'll have a real mess on your hands. I also had a bit of trouble

gluing the wing in this area. I pre-glued it, but overdid it a bit as some

glue oozed out of the join opposite the flaps/ailerons when I fit the upper

wings in plad, and stuck them up. Fortunately, I discovered the glitch and

spent quality time moving these up and down to keep the glue from drying

completely and freezing them in place. During this one of the right flap

hinge attachments broke loose inside the wing. No way to fix it so

hopefully it won't be real noticeable. The upper wings did fit quite well.

The other part of the modeling time was spent on some

controls. For the wing, I superglued the little etched 'hooks' into the

lower half of the wing for each surface. You have to use accelerator on

these or you'll have a real mess on your hands. I also had a bit of trouble

gluing the wing in this area. I pre-glued it, but overdid it a bit as some

glue oozed out of the join opposite the flaps/ailerons when I fit the upper

wings in plad, and stuck them up. Fortunately, I discovered the glitch and

spent quality time moving these up and down to keep the glue from drying

completely and freezing them in place. During this one of the right flap

hinge attachments broke loose inside the wing. No way to fix it so

hopefully it won't be real noticeable. The upper wings did fit quite well.

There are also little forward hinged areas on the front of

the radiator inlets. These can be cemented in the lowered position if one

wants, but rarely are they seen like this unless the engine is running. It

is unfortunate that they don't fit as well as most of us would like in the

'up' position. Finally, I glued one of the elevators onto the lower section

and left the top of the tailplane off so you could see how they are

attached.

October 13

Well, today

was a big day; the wing to fuselage mating ceremony! I first test fit it to

ensure no glitches. I found one and fixed it by trimming off the sprue

stubs on the inside of the upper wings. Just goes to prove that cleaning

every bit helps. The fit of the wing was really very g

Well, today

was a big day; the wing to fuselage mating ceremony! I first test fit it to

ensure no glitches. I found one and fixed it by trimming off the sprue

stubs on the inside of the upper wings. Just goes to prove that cleaning

every bit helps. The fit of the wing was really very g ood.

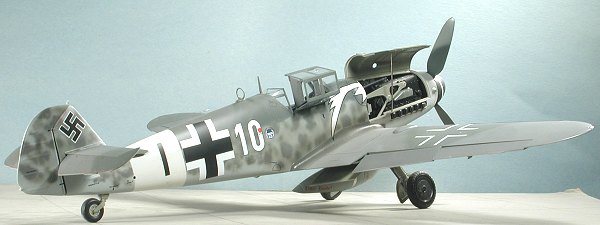

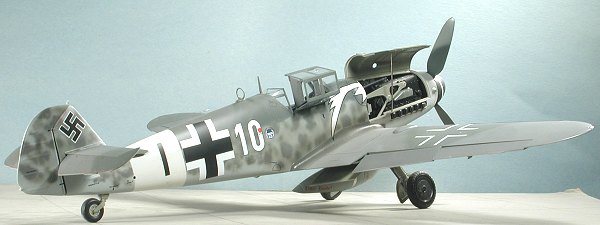

As you can see from the images, most of it was very tight and that was

especially true of the upper wing join. The very front will need a bit of

filler and a lot more will be needed in the back. There is a rather

substantial gap and were I to do this kit again, I'd stick in a small

section of card back there prior to gluing on the wing.

ood.

As you can see from the images, most of it was very tight and that was

especially true of the upper wing join. The very front will need a bit of

filler and a lot more will be needed in the back. There is a rather

substantial gap and were I to do this kit again, I'd stick in a small

section of card back there prior to gluing on the wing.

While I had the wing there, I sanded all the joins where

I'd glued it yesterday. It looks pretty clean so perhaps no filler will be

needed there, either. I also took the time to add filler to the outer aft

wing roots as the seam there will be visible when the cooler doors are

glued in place. I also glued on the drop tank rack. The large indented hole

in the front can be drilled out if one wants. I'd have liked to have seen

some bolt head detail on the four attachment areas on the rack. Hasegawa

has no trouble providing that in

1/48. The rack is properly

offset. On the upper side, I installed the small hatch on the back of the

cockpit. Fit is fairly good, but could be better as it leaves some small

gaps. Paint should fill those.

1/48. The rack is properly

offset. On the upper side, I installed the small hatch on the back of the

cockpit. Fit is fairly good, but could be better as it leaves some small

gaps. Paint should fill those.

On other items, I sanded down the filler on the prop hub

and repainted the blades with Testors RLM 70 enamel. I also took the

opportunity to attach the other elevator and glue the two tail planes.

These were then sanded smooth. I cut the canopy and windscreen from the

sprues and masked them. A rather easy job, but I did notice that the upper

frame line on the canopy and the windscreen was particularly indistinct.

The clear is also not very clear and has quite a few stress lines in it. It

seems as if there is a small etched section on the windscreen that is for a

desiccant pack for the pressurized version. However, it isn't on any of the

other clear bits. It basically means that your windscreen isn't totally

clear and there is nothing you can do about it as it appears it won't sand

out. The small areas around where the handle for the canopy sliding section

is located is also just as etched as the windscreen section. I should

mention that the rear section seems somewhat oddly done at the very bottom.

It has a notch in it which corresponds with a similar notch in the

fuselage. I had always thought that the rear of the back piece was a

straight shot down to the lower canopy line. According to the reference,

it is not and this notch should be there.

October 14

Work steadily

continues as the number of unused parts in the box dwindles down to a mere

shadow of its former self. Today's work consisted mainly of sanding and

some small component builds. First of all, I sanded down the tail planes to

get rid of the glue oozes. It was then that I noticed some sink areas on

one side. Apparently, I had gotten too much glue in the alignment

receptacles and it had softened the plastic. I filled those with putty and

sanded it smooth once it had dried. You can spot those areas on the

picture.

Work steadily

continues as the number of unused parts in the box dwindles down to a mere

shadow of its former self. Today's work consisted mainly of sanding and

some small component builds. First of all, I sanded down the tail planes to

get rid of the glue oozes. It was then that I noticed some sink areas on

one side. Apparently, I had gotten too much glue in the alignment

receptacles and it had softened the plastic. I filled those with putty and

sanded it smooth once it had dried. You can spot those areas on the

picture.

Next, I glued the oil radiator into the lower cowling bath

and glued that to the lower cowling. There is a small support rod that

needs to be glued in place and it is a bit fiddly to get into the slots. As

you can see, I sprayed the cooler bath area RLM 02 prior to attaching the

bath. That will be resprayed a bit later. I also glued on the cooler aft

door in the open position.

The supercharger intake was painted RLM 02 on the inside as

was the mounting area and then it was glued in place. I also painted the

inside of the engine cowlings RLM 02. For those that wish to have the

cowlings open, the mounting holes for the supercharger will have to be

filled as will several ejector pin indentations.

Moving to the landing gear, I put the springs in place and

then glued in the small plastic pins. These pins fit into slots in the

lower portion and allow the lower section to move up and down. The holes

for these pins will have to be enlarged as they are a touch too small.

There are holes on both sides, but one needs to use those that will be on

the same side as the oleo scissors. The other hole is to be used to mount

the gear doors.

Finally, I smoothed out the filler I placed on the leading

edge of the wing and had to put a second coat on the aft wing/fuselage join

as the wing in that area is lower than the fuselage. Though not shown, I

also glued the aft cowling breech covers onto the fuselage and painted the

spinner and backing plate black. Depending on the markings I'm going to

use, I may have to do some repainting on the spinner, but it came black

from the factory so at least I won't have too much extra to do!

October 15

Today, things

really started coming together. I glued on the tailplanes. Fit is rather

good with each side tabbed to prevent getting things on the wrong side. I

also glued on the canopy. This is a touch small for the cockpit opening. I

feel that adding filler to try to blend things in will only make this even

more noticeable so will leave it as is until the first coat of paint. That

should show how nasty things may be.

Today, things

really started coming together. I glued on the tailplanes. Fit is rather

good with each side tabbed to prevent getting things on the wrong side. I

also glued on the canopy. This is a touch small for the cockpit opening. I

feel that adding filler to try to blend things in will only make this even

more noticeable so will leave it as is until the first coat of paint. That

should show how nasty things may be.

I also discovered that I left out the front wing radiator

actuator rods. I pulled out the forward ramps and glued in the rods.

Somehow, one of them got away from me and is now permanently hidden in the

bowels of the wing. I had to substitute a piece of stretched sprue. I also

glued on the slats in the open position. These don't open very far so make

sure you don't overdo it on yours.

In the paint department, I put another coat of paint on the

lower cowling to take care of the RLM 02 that was on there. I also finished

painting the prop by doing the prop hub in Alclad II aluminum. Likewise the

drop tank was finished by doing it in RLM 76.

Sanding the rear wing/fuselage join showed that still a bit

more filler was needed so that was applied. I also glued the upper aft wing

radiator coolant flap level with the wing. They are molded to be up

slightly higher than the wing, but rarely have I seen a p hoto of them in

that position. They are usually both drooped down or the upper is flat with

the lower one drooping. I also noted that there are no shell ejector tubes

for the upper guns. This means that there is a 'see-through' from the

ejector slots in the lower fuselage up through the engine. Most noticeable

when the cowling covers are off.

hoto of them in

that position. They are usually both drooped down or the upper is flat with

the lower one drooping. I also noted that there are no shell ejector tubes

for the upper guns. This means that there is a 'see-through' from the

ejector slots in the lower fuselage up through the engine. Most noticeable

when the cowling covers are off.

October 16

As much as I wanted to spend quality time working on the

model today, too many other things came up to occupy my time, including

having to get Friday's kit finished! However, not all was lost. I did

manage to sand off the third coat of filler on the lower wing/fuselage

join. Then I sprayed the windscreen and the back section RLM 66 and

finished the touch-up spraying of this color on the other canopy bits. I

also did some RLM 76 painting on the underside of the tailplanes and a few

other areas to check for gaps.

When all that was dry, I broke out my micro saw and pin

vice and spent some quality time trying to replace some lost panel lines

and rivet detail! The sharp-eyed will note that one of the cowl guns has

gone missing as I managed to have it come loose during all the handling!

On to page 4

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to

Contributors.

Back to the Main Page

Back to the Reviews Index

Page

With a

contest last Saturday, it meant that Friday was spent getting ready for it

and most of today spent recuperating from it! However, I did manage to do a

few things on it late this evening. First, I cut the prop blade/hub bits

from the sprues. I'd already painted the prop blades, but that was sort of

ruined by the need to sand on the tips where the sprue gates were located.

Next I attached them to one half of the hub and glued the other atop it.

Fit isn't very good as I had a gap all around it. That was clamped in place

and when dry, filler placed into the spaces. Now I do realize that much of

this won't be seen once I get the spinner in place, but the flashlight gang

will be able to peer in there and so I wanted to get it smoothed out.

With a

contest last Saturday, it meant that Friday was spent getting ready for it

and most of today spent recuperating from it! However, I did manage to do a

few things on it late this evening. First, I cut the prop blade/hub bits

from the sprues. I'd already painted the prop blades, but that was sort of

ruined by the need to sand on the tips where the sprue gates were located.

Next I attached them to one half of the hub and glued the other atop it.

Fit isn't very good as I had a gap all around it. That was clamped in place

and when dry, filler placed into the spaces. Now I do realize that much of

this won't be seen once I get the spinner in place, but the flashlight gang

will be able to peer in there and so I wanted to get it smoothed out. The other part of the modeling time was spent on some

controls. For the wing, I superglued the little etched 'hooks' into the

lower half of the wing for each surface. You have to use accelerator on

these or you'll have a real mess on your hands. I also had a bit of trouble

gluing the wing in this area. I pre-glued it, but overdid it a bit as some

glue oozed out of the join opposite the flaps/ailerons when I fit the upper

wings in plad, and stuck them up. Fortunately, I discovered the glitch and

spent quality time moving these up and down to keep the glue from drying

completely and freezing them in place. During this one of the right flap

hinge attachments broke loose inside the wing. No way to fix it so

hopefully it won't be real noticeable. The upper wings did fit quite well.

The other part of the modeling time was spent on some

controls. For the wing, I superglued the little etched 'hooks' into the

lower half of the wing for each surface. You have to use accelerator on

these or you'll have a real mess on your hands. I also had a bit of trouble

gluing the wing in this area. I pre-glued it, but overdid it a bit as some

glue oozed out of the join opposite the flaps/ailerons when I fit the upper

wings in plad, and stuck them up. Fortunately, I discovered the glitch and

spent quality time moving these up and down to keep the glue from drying

completely and freezing them in place. During this one of the right flap

hinge attachments broke loose inside the wing. No way to fix it so

hopefully it won't be real noticeable. The upper wings did fit quite well. Well, today

was a big day; the wing to fuselage mating ceremony! I first test fit it to

ensure no glitches. I found one and fixed it by trimming off the sprue

stubs on the inside of the upper wings. Just goes to prove that cleaning

every bit helps. The fit of the wing was really very g

Well, today

was a big day; the wing to fuselage mating ceremony! I first test fit it to

ensure no glitches. I found one and fixed it by trimming off the sprue

stubs on the inside of the upper wings. Just goes to prove that cleaning

every bit helps. The fit of the wing was really very g ood.

As you can see from the images, most of it was very tight and that was

especially true of the upper wing join. The very front will need a bit of

filler and a lot more will be needed in the back. There is a rather

substantial gap and were I to do this kit again, I'd stick in a small

section of card back there prior to gluing on the wing.

ood.

As you can see from the images, most of it was very tight and that was

especially true of the upper wing join. The very front will need a bit of

filler and a lot more will be needed in the back. There is a rather

substantial gap and were I to do this kit again, I'd stick in a small

section of card back there prior to gluing on the wing. 1/48. The rack is properly

offset. On the upper side, I installed the small hatch on the back of the

cockpit. Fit is fairly good, but could be better as it leaves some small

gaps. Paint should fill those.

1/48. The rack is properly

offset. On the upper side, I installed the small hatch on the back of the

cockpit. Fit is fairly good, but could be better as it leaves some small

gaps. Paint should fill those.  Work steadily

continues as the number of unused parts in the box dwindles down to a mere

shadow of its former self. Today's work consisted mainly of sanding and

some small component builds. First of all, I sanded down the tail planes to

get rid of the glue oozes. It was then that I noticed some sink areas on

one side. Apparently, I had gotten too much glue in the alignment

receptacles and it had softened the plastic. I filled those with putty and

sanded it smooth once it had dried. You can spot those areas on the

picture.

Work steadily

continues as the number of unused parts in the box dwindles down to a mere

shadow of its former self. Today's work consisted mainly of sanding and

some small component builds. First of all, I sanded down the tail planes to

get rid of the glue oozes. It was then that I noticed some sink areas on

one side. Apparently, I had gotten too much glue in the alignment

receptacles and it had softened the plastic. I filled those with putty and

sanded it smooth once it had dried. You can spot those areas on the

picture.  Today, things

really started coming together. I glued on the tailplanes. Fit is rather

good with each side tabbed to prevent getting things on the wrong side. I

also glued on the canopy. This is a touch small for the cockpit opening. I

feel that adding filler to try to blend things in will only make this even

more noticeable so will leave it as is until the first coat of paint. That

should show how nasty things may be.

Today, things

really started coming together. I glued on the tailplanes. Fit is rather

good with each side tabbed to prevent getting things on the wrong side. I

also glued on the canopy. This is a touch small for the cockpit opening. I

feel that adding filler to try to blend things in will only make this even

more noticeable so will leave it as is until the first coat of paint. That

should show how nasty things may be. hoto of them in

that position. They are usually both drooped down or the upper is flat with

the lower one drooping. I also noted that there are no shell ejector tubes

for the upper guns. This means that there is a 'see-through' from the

ejector slots in the lower fuselage up through the engine. Most noticeable

when the cowling covers are off.

hoto of them in

that position. They are usually both drooped down or the upper is flat with

the lower one drooping. I also noted that there are no shell ejector tubes

for the upper guns. This means that there is a 'see-through' from the

ejector slots in the lower fuselage up through the engine. Most noticeable

when the cowling covers are off.