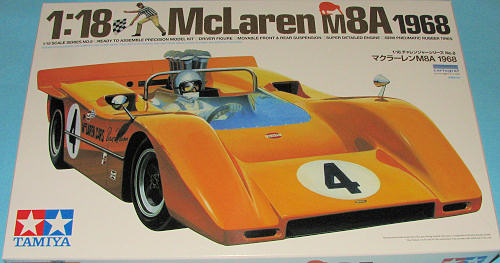

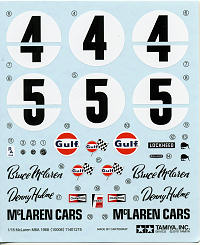

Bruce McLaren and his team mate Denny Hulme set a unique pattern in 1967 when they finished first and second in the dollar rich Canadian-American series for Group 7 sports cars. They alone of the European constructors realized the prestige to be gained from winning the series as well as the not inconsiderable prize money and the orders for replica cars for the next year’s series. In fact so large was the order book at the end of the 1967 series that the small Bruce McLaren Motor Racing factory near Slough could not cope and they were glad of their tie-up with the Lambretta Trojan people who had previously built Elva sports/racing car under license. Under the licensing agreement Trojan were to build the production versions of the McLaren, leaving the McLaren factory free to build the works cars and prototypes. Thus the 1967 factory car the M6A became the production M6B and the 1968 factory car the M8A became the M12; the inconsistency in type numbers is explained by the fact that the works decided to call the 1969 factory car the M8B because it was changed very little in basic design.

The formula for this Can-Am series is pretty simple; virtually any size of engine is allowed and you can fit it to any two-seater racing car. Since very powerful pushrod ohv engines are available in America most teams used these, although Ferrari belatedly entered a 6.2 litre four overhead camshaft V12 which showed promise. In 1968 General Motors, who are allegedly against racing, produced a special batch of all aluminum 7-litre pushrod Chevrolet engines which were sold to Can-Am contestants at a fairly low price. The leading teams all used these and the rival Ford engine hardly got a look-in. The McLaren engine men went over the engines with a fine tooth comb and found a few more horsepower as well as converting them to fuel injection and they ended up with something like 620bhp which gave these exciting sports cars a top speed of over 200mph on the fastest circuits.

The basis of the M8A is a very stiff but light monocoque chassis built from aluminum with steel bulkheads which finishes just behind the cockpit, with the engine acting as a stressed member being bolted directly to the rear of the cockpit with the rear suspension mounted on the gearbox. This saves a great deal of weight which is all important in any type of racing. The side boxes of the monocoque tub carry the rubber fuel bags which hold a total of 52 gallons of fuel - very necessary at under 6mpg!

The front suspension is by double wishbones with outboard mounted coil spring/damper units while at the rear the usual single transverse top links, lower reversed wishbones, and radius arms are fitted, the radius arms being the only connection the rear suspension has with the chassis as these are mounted at the forward end of the rear of the monocoque. The brakes are Lockheed 12in ventilated discs outboard mounted all round with plenty of cool air ducting. Steering is by rack and pinion, and wheels are McLaren castings of 15in diameter with 10in rims at the front and 15in at the rear.

The 7-litre aluminum engine supplied by Chevrolet is among the most powerful racing anywhere today even though it uses ordinary pushrod overhead valves. Converted by McLaren to use Lucas petrol injection the engine gives no less than 620bhp at 7,000rpm from its 7 litres (427 cu.in.) and is very light as well. It transmits its power through a Borg and Beck tripe-plate clutch to a very strong Hewland LG 50- 4-speed gearbox.