Hasegawa 1/200 B.767-200

A Primer on building Airliner Models

|

KIT # |

Lc13 |

|

PRICE: |

$17.00 |

|

DECALS: |

See review |

|

REVIEW : |

|

|

NOTES: |

|

A primer on building airliner models

|

HISTORY |

The 767 is a fourth-generation airliner developed with an eye on

improved fuel economy, better performance and the desire for a 'wide body'

medium/long range airliner. To give this, the 767 has 3-2-3 seating in coach

class, fuel efficient high-bypass turbofans and the ability to fly on only one

engine, thanks to the excess thrust provided by its new engines. The 767 is also

one of the earlier airliners to go to the 'glass cockpit' design of digital

instruments and CRTs. The aircraft is still in production at Boeing's plant in

Washington state.

|

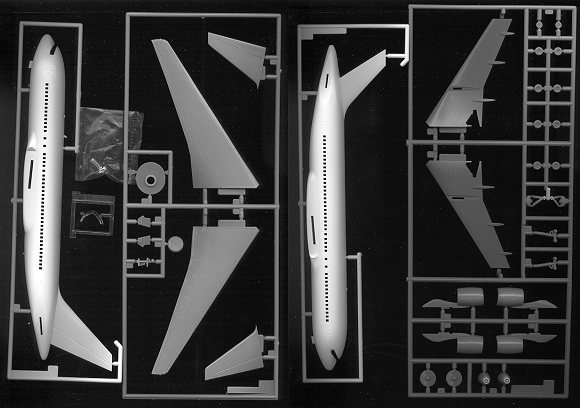

THE KIT |

While it may be

a model of a fourth generation airliner, this is a first generation Hasegawa

airliner. As a result, nearly all the panel lines are raised. It also has a

separate transparency for the windscreen, though none for the cabin windows.

There is no interior or cockpit in this scale. The kit is designed to be built

wheels down so any desire to display it in flight will require some card stock

and filler. A nice nose weight in the form of a big screw is provided. To

display it on its stand, a hole in the fuselage bottom will have to be

opened. Just

a note, this is a 767-200. Most of the currently available kits are the longer

-300 version. There is a note in the Liveries Unlimited sheet stating that the

-200 molds were permanently modified to make the -300, however a quick

check of the Hobby Link Japan website does show a couple of -200 kits still

available. It is quite possible that these are left-overs from the -200

production run and just reboxed with new decals.

I bought this kit on the second hand market and as

such, it didn't come with a decal sheet. Not a problem as I plan on using

Liveries Unlimited's new 767 Ethiopian Airlines sheet for this one.

I bought this kit on the second hand market and as

such, it didn't come with a decal sheet. Not a problem as I plan on using

Liveries Unlimited's new 767 Ethiopian Airlines sheet for this one.

|

CONSTRUCTION |

Meanwhile, I glued together some of the other components

including the wings and the engines. You can leave off the aft section of the

engine until the final construction as they just pop right in. Back

at the fuselage; after four filler applications (actually, it isn't as bad as it

sounds because the third and fourth application were just spot ones to take care

of some rough spots), the fuselage was pretty smooth and ready to go. The way to

tell if you have it smooth enough is

to run your finger over the window areas. If you can

Once

the wings were smoothed up a bit on the leading edge, any areas that needed some

filler were attended to. Then the wings were glued onto the wing root. Mine fit

pretty well, though the very front part was in need of filler. I suspect I had

gotten too eager with the sandpaper doing the fuselage! Once all

that was done, the kit was set aside for about two weeks. This let the filler do

a good job of completely curing. After that time, it was obvious by running my

finger over the fuselage windows that another application of filler was needed.

That was done and smoothed down. Another day or two of curing and it was of to

the paint shop for the first application of paint.

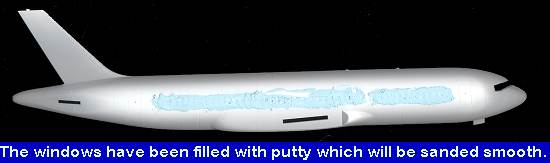

The first step was

to decide if I wanted to fill in the cabin windows. Most airliner modelers

replace these with decals and since the decals I am going to use included

windows, that is what I did. First of all, I used some strip styrene to back up

the windows so that I wouldn't have an interior full of bits of putty. Then the

nose weight was installed in one fuselage half. This wasn't painted as suggested

in the instructions as the windscreen would be filled in as well for the

decal.

The first step was

to decide if I wanted to fill in the cabin windows. Most airliner modelers

replace these with decals and since the decals I am going to use included

windows, that is what I did. First of all, I used some strip styrene to back up

the windows so that I wouldn't have an interior full of bits of putty. Then the

nose weight was installed in one fuselage half. This wasn't painted as suggested

in the instructions as the windscreen would be filled in as well for the

decal.

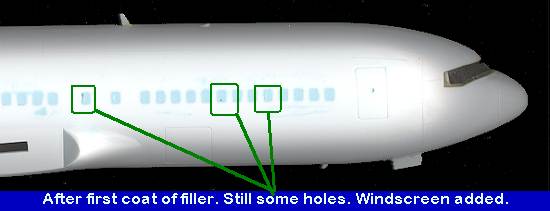

When dry, the first

of several coats of filler was applied. I say several coats as fillers tend to

shrink, leaving indentations of where the windows were. For the decals to be

effective, the fuselage must be very smooth. After the first coat was applied,

the fuselage halves were glued together. Once the fuselage halves were

dry, the windscreen was glued in place. I figured I may as well get all

the fuselage puttying done at the same time!

When dry, the first

of several coats of filler was applied. I say several coats as fillers tend to

shrink, leaving indentations of where the windows were. For the decals to be

effective, the fuselage must be very smooth. After the first coat was applied,

the fuselage halves were glued together. Once the fuselage halves were

dry, the windscreen was glued in place. I figured I may as well get all

the fuselage puttying done at the same time!

feel the windows, it needs

more filler. Alternatively, you can get it as smooth as you can and hope that

the paint will take care of any minor rough spots. You can see my final result

on the image to the left. It was now time to add the wings.

feel the windows, it needs

more filler. Alternatively, you can get it as smooth as you can and hope that

the paint will take care of any minor rough spots. You can see my final result

on the image to the left. It was now time to add the wings.

|

PAINT |

During all of this, the

engines and pylons were painted. Despite being rather small bits, they require

the same three colors that the rest of the aircraft does as well as some extra.

The pylons are in the grey color. These were then masked and the cowlings

painted white. Then the body was masked and just the edges of the intake and the

inside of the intake were painted aluminum. The exhaust cones are two colors,

aluminum and a darker metal. I used Magnesium. Again, the Aluminum Metallizer

was masked with no problems. The landing gear components and wheel wells are

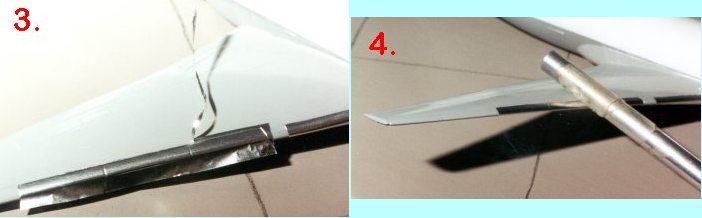

grey (like the underside) and the wheels are aluminum. USING BARE METAL FOIL Next step was to apply the

Bare Metal Foil (BMF) on the leading edges of the tail, tailplanes and wings.

This stuff really is great. The one thing those of you new to it will notice, is

that you tend to waste most of it. This cannot be helped as you want to make

sure you have enough to cover the spot. Putting it on is actually quite

simple. Just follow the steps below. The pictures of various steps are

numbered and shown below.

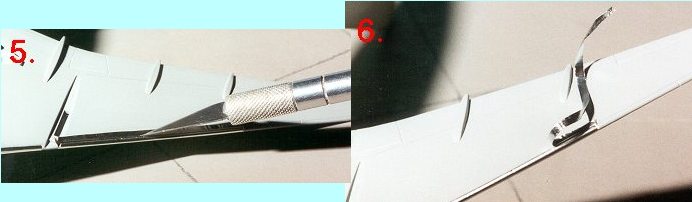

First, you cut a section out of the sheet. By this,

I don't mean you actually cut the backing, but you do want to slice through the

foil itself. A new blade is paramount for using BMF. Take the piece and

place it over the area to be foiled (1). Then burnish down one side of it. I use an

Xacto knife handle wrapped in tape(2). The tape is softer than the handle and has

some give to it. You can also use a toothpick as it is handy for tight places.

Once the one side is burnished down, you'll see where to cut it. In this case it

is a slat groove. Cut one side and remove the excess(3). Then burnish

it down again to smooth out any ragged edges you may have from cutting it(4).

Burnish

the rest of

the BMF around the leading edge and onto the underside. Again, cut the BMF(5). I make sure that I cut the foil at a natural break in the aircraft

metal like a panel line or something similar. This is especially helpful when

doing a long area. That way, you can do it in segments. If there are no seams to

follow, as on the tail, then you just have to freehand it. Others have told me that

they can burnish overlapping foil areas and have the seam disappear, but I have

never been able to do it to my satisfaction. Once the foil is cut,

then carefully remove the excess(6). Then burnish

this piece down on the aircraft. If you want, you can follow up by burnishing

the completed section with a Q-tip or cotton bud. That will help push the foil

into seams. After all the areas are finished(7),

you are ready to go onto the next stage.

The Ethiopian Airlines planes are, like most airliners today,

mostly white and grey. Being a Boeing aircraft, there is a non-standard grey

that is used on all their aircraft. This color is made by Xtracolor, but the

paint is often difficult to find. After many e-mails and inquiries, I was told

that probably the best substitute is Testors Canadian Voodoo Grey, a paint that

is quite easy to find. The tailplanes were snapped into place and they, as well

as the wings and engine pylons, were painted in Voodoo Grey. All the areas of

filler were also painted this color. The reason being is that regardless of how

many coats of white one puts over bare filler, the filler always seems to show

through! The Voodoo Grey also helps to fill any tiny pinholes that inevitably

show up in fillers.

The Ethiopian Airlines planes are, like most airliners today,

mostly white and grey. Being a Boeing aircraft, there is a non-standard grey

that is used on all their aircraft. This color is made by Xtracolor, but the

paint is often difficult to find. After many e-mails and inquiries, I was told

that probably the best substitute is Testors Canadian Voodoo Grey, a paint that

is quite easy to find. The tailplanes were snapped into place and they, as well

as the wings and engine pylons, were painted in Voodoo Grey. All the areas of

filler were also painted this color. The reason being is that regardless of how

many coats of white one puts over bare filler, the filler always seems to show

through! The Voodoo Grey also helps to fill any tiny pinholes that inevitably

show up in fillers.

|

DECALS |

Once finished with the BMF, I used a product by

Liveries Unlimited called Corroguard Inspar Panels. These are decals that are

used for the sections in the middle of wings and stabilizers. On real airliners,

these areas are treated with a material called Corroguard that helps prevent

corrosion. These decals duplicate that material and save you having to paint

them in. They are available for all sorts of aircraft in both 1/144 and 1/200

scale and cost between $2-$5 depending on the aircraft. Naturally a set for the

747 will be more expensive than for a DC-9. They are easy to apply and really

look nice when done.

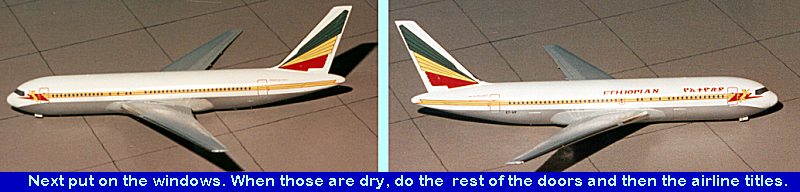

Next the decals were applied. I used Liveries Unlimited set AGA2-101 for an

Ethiopian Airlines 767-200. It is a very nice and colorful scheme and hasn't

been turned into a billboard like so many other airlines. The first parts I

applied were the cockpit windows and the tail markings. I did the cockpit early

so that I would have a reference for the cheat line and cabin windows. The

next part to be added was the cheat line. This will determine the placement of

most of the rest of the decals. I lined mine up and made sure it went through

the tail plane attachment slot. It is important that you do NOT glue the

tailplanes on this kit until the very end or this sequence will be a real

disaster as you can see from the images below. I also put on the big tail marking at this time.

Once

the cheat lines are in place and dry, you can add the fore and aft cabin doors.

It was at this time that I discovered that I put my cheat line too high! Well,

this makes error # 5,384,704 in my modeling career! I just had to grin and

bear it as my success rate with refloating decals of this size is about zero.

Once the fore and aft cabin doors were in place and dry, I put on the first of

the cabin windows. The front one is rather easy to put in place. Just remember

not to put them in backwards. The part with all the gaps is to the aft. The rear

section looks like a uniform row, but you'll notice one decal slightly

farther away from the others. This is for the emergency exit so needs to go to

the front of that decal section.

Once those are dry, there

is another decal that overlays them that is for window frames. You can omit it

if you wish and no-one would be the wiser as they are not very obvious. I used

them. Now you can put on the wing emergency exit door. It goes over the one

window in the aft section that stands a bit apart of the others. Once that is on

and dry, you can place the wing emergency exit walkway under that door. The

rest of the decals are pretty easy to put on. Just follow the guide and take

your time. The most difficult of the other decals is the black outline to the

lion on the front of the cheat line. Again, easy does it. The 'Boeing 767-200'

logos for aft of the rear cabin door are handed so make sure the proper one goes

on the proper side. Throughout the decaling operation I used the Microscale

setting solutions. These work very well and don't cause the colors to bleed, a

problem you may encounter with stronger solutions. After the decals are good and

dry, wipe down the aircraft with water and dry it thoroughly. You can then spray

on your favourite clear overcoat to seal them in.

|

CONSTRUCTION |

The final constructions of sorts consisted of snapping

the nose gear into place as well as gluing the main landing gear and struts into

the wings. A helpful hint is to let the gear dry with the weight of the aircraft

on it. That way you can be sure that all the wheels touch the ground. Make sure

this is done on a solid, flat surface. Last but not least, the engines were

pressed into place under the wings. As you may have noticed, I prefer to press

fit as much as possible. This leaves less chance for glue to mess something up,

especially with all the decals used on this aircraft.

Now you should have a pretty complete-looking aircraft. The only

things left to put on it are the horizontal stabilizers, engines, and the

landing gear stuff. With my kit, the stabilizers just snapped into place without

the need for glue. Same with the engines and pylons. The landing gear components

that had previously been painted, were now assembled. I don't know about you,

but painting all those tiny wheels was not my idea of tons of fun. I'm just glad

I wasn't building a C-5! These were then glued into place in their respective

locations.

Now you should have a pretty complete-looking aircraft. The only

things left to put on it are the horizontal stabilizers, engines, and the

landing gear stuff. With my kit, the stabilizers just snapped into place without

the need for glue. Same with the engines and pylons. The landing gear components

that had previously been painted, were now assembled. I don't know about you,

but painting all those tiny wheels was not my idea of tons of fun. I'm just glad

I wasn't building a C-5! These were then glued into place in their respective

locations.

|

CONCLUSIONS |

There you have it. A completed airliner kit. These construction

techniques can be used with airliners of any scale and complexity. What looks

like a quick build can take a bit of time, but the result is well worth the

effort. The nice thing about most of these 1/200 kits is that they can be built

in just a very few hours if one wants to. It is a nice introduction to the genre

for newer modelers and one doesn't have to fuss with interiors or other things

like that.

I can recommend any of the Hasegawa 1/200 kits to those who like

airliners or just want to do something different.

July 2000

Copyright ModelingMadness.com. All rights reserved Review kit courtesy of me and my wallet; decals

If you would like your product reviewed fairly and fairly quickly by a site that has over 1,000 visits a day, pleasecontact the editor or see other details in the Note to Contributors.