| KIT #: | 2600 |

| PRICE: | $57.00 from Cooper's Models |

| DECALS: | One option |

| REVIEWER: | Scott Van Aken |

| NOTES: | Short run resin kit with vacuform canopy |

| HISTORY |

The

SNCASE S.E.5000

Baroudeur was a

lightweight fighter, designed to operate from grass airfields. It used a

wheeled trolley that could be used for take off from grass, and three

retractable skids, the third at the tail for landing and for take off

from snow or ice-covered surfaces. The three wheeled trolley had

provision to use rockets (two or four according to terrain plus two

back-up) if needed to assist. Apart from the landing gear the aircraft

was a conventional shoulder-wing monoplane with a 38 degree swept wing

and tail surfaces and powered by a SNECMA Atar 101C turbojet with

wing-root intakes. The first of two prototypes flew on the 1 August

1953. Three pre-production aircraft designated the

S.E.5003

were also built with Atar 101D turbojet engines but the type was not

ordered into production.

The

SNCASE S.E.5000

Baroudeur was a

lightweight fighter, designed to operate from grass airfields. It used a

wheeled trolley that could be used for take off from grass, and three

retractable skids, the third at the tail for landing and for take off

from snow or ice-covered surfaces. The three wheeled trolley had

provision to use rockets (two or four according to terrain plus two

back-up) if needed to assist. Apart from the landing gear the aircraft

was a conventional shoulder-wing monoplane with a 38 degree swept wing

and tail surfaces and powered by a SNECMA Atar 101C turbojet with

wing-root intakes. The first of two prototypes flew on the 1 August

1953. Three pre-production aircraft designated the

S.E.5003

were also built with Atar 101D turbojet engines but the type was not

ordered into production.

| THE KIT |

This

is a short run resin kit straight from the old school of garage kits. This

means that the parts are fairly well molded, though they have air pockets in

various spots and there is a goodly amount of resin flash to take care of.

Many of the parts are in resin wafers. I have not shown all the parts in the

photo as most of them came loose from their sprues/wafers and were in with a

mass of shavings in the bag. However, these images are pretty typical of how

the pieces look.

It means that this kit is not for the beginner, but for those who have had

experience building resin kits. And that is just fine. Modelers who are

attracted to things like this are fully aware that additional and in some

cases considerable work will need to be done to produce a finished model to

acceptable standards.

It means that this kit is not for the beginner, but for those who have had

experience building resin kits. And that is just fine. Modelers who are

attracted to things like this are fully aware that additional and in some

cases considerable work will need to be done to produce a finished model to

acceptable standards.

There are about 20 parts to this kit, several of them making up the

launching and handling trolley. The fuselage is in three parts; two main

fuselage halves and a complete tail section. Test fitting of the forward

halves shows the fit to be good and the panel lines match from side to side.

The horizontal stab slots into the fin. Wings are of tab and slot, though

Akatombo recommends a wire stub reinforcement. The cockpit is quite basic

consisting of a seat and instrument panel/combing. No control stick, rudder

pedals or other interior embellishments. The instructions recommends

"Complete cockpit details by adding if desired". Five grams of nose weight

is suggested and there is room in the hollowed out fuselage for that. A

single vacuformed canopy is provided as is a mold for making more if you

need to do so. This is a nice addition, though I would have rather had a

ready to go spare canopy.

The

trolley takes up a goodly number of parts with a frame, main wheels, nose

'strut' with dual wheels and fenders. There is supposed to be a wire mesh

tray covering most of the underside, but this will have to be scratch built.

The

trolley takes up a goodly number of parts with a frame, main wheels, nose

'strut' with dual wheels and fenders. There is supposed to be a wire mesh

tray covering most of the underside, but this will have to be scratch built.

Instructions are basically a list of suggestions and an exploded view of all

the parts. Pinched from Wings of Fame or Air International is a nicely drawn

cut away. Another sheet includes 1/72 plans and there is a glossy sheet with

well over a dozen nicely done photographs of the real aircraft to provide

assistance. This includes several close up images of the skids and the

trolley. A decal sheet is provided for the kit. The decals are nicel

printed, quite flat and do not seem to have any carrier. However, Atakombo

provides more than are needed so one can use one to experiment. One could

use aftermarket for the roundels if needed. No markings diagram is given,

though one has the box art and photos that can be used for this purpose.

From what I recall reading one of the references provided on the sheet

several years back, the aircraft was unpainted metal.

| CONSTRUCTION |

Typical of these sorts of kits, one spends a considerable amount of time cleaning things up. This included sanding all the mating surfaces as flat as one can and removing the flash from the edges of all the parts. I generally wet sand these things to keep dust down to a minimum or wear a dust mask.

This kit had quite a few air pockets and on some

parts, some pinholes that needed filling. This was particularly the case with

the aft fuselage section. I normally use thin super glue for this. Fortunately,

these pinholes were not rampant and even after some considerable sanding on a

few parts, no new ones appeared.

This kit had quite a few air pockets and on some

parts, some pinholes that needed filling. This was particularly the case with

the aft fuselage section. I normally use thin super glue for this. Fortunately,

these pinholes were not rampant and even after some considerable sanding on a

few parts, no new ones appeared.

Once the fuselage halves were cleaned up, they were joined. Though there were the expected seams, the fit of these parts is generally quite good as they were keyed. I particularly liked that the nose cone was molded into one half as a complete unit. After much work, the tail section was attached. Not unexpectedly, this did not match the fuselage, being wider in some parts. This left a goodly step that needed considerable sanding to remove. Fortunately, there is not a ton of engraved detail, so replacing what was sanded away was not an issue.

I then turned to the wings. The

I then turned to the wings. The se have the usual air

pockets and a few voids as well. I found one on the wing fence and so cut a

notch in it and installed a small section of plastic card that was later sanded

down. Meanwhile, clean-up continued with the launch/handling trailer. For some

reason, I got two sets of wheels and front axles for this. They all look the

same so I am not sure what the deal is on this. This piece suffers from a bit of

mold mismatch. Sanding it down and getting everything in the nooks and crannies

required the use of files and a lot of patience. There were also some voids,

though some went untreated due to where they were. In case you have not guessed,

there were no parts that did not require some sort of remedial work to bring them up to

acceptable standards.

se have the usual air

pockets and a few voids as well. I found one on the wing fence and so cut a

notch in it and installed a small section of plastic card that was later sanded

down. Meanwhile, clean-up continued with the launch/handling trailer. For some

reason, I got two sets of wheels and front axles for this. They all look the

same so I am not sure what the deal is on this. This piece suffers from a bit of

mold mismatch. Sanding it down and getting everything in the nooks and crannies

required the use of files and a lot of patience. There were also some voids,

though some went untreated due to where they were. In case you have not guessed,

there were no parts that did not require some sort of remedial work to bring them up to

acceptable standards.

I also worked on the wings some more. The other wing had a chip on the trailing edge of the wing at the fuselage join and at the lower intake. These were handled just like the wing fence with plastic card, super glue and sanding down.

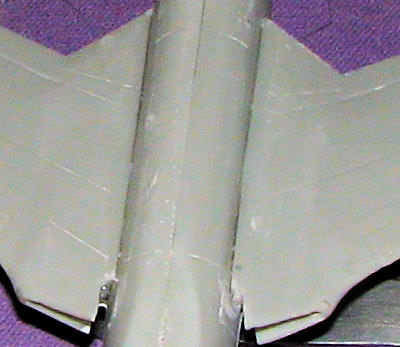

The

next step was to attach the wings. These are not really molded to fit well. Even

after lots of trimming of the attachment holes and wing root itself to try to

conform to the curve of the fuselage, I was left with very large gaps. Super

glue was used to fill these once I got the wings somewhat even with each other.

Use the engraved attachment lines on the fuselage as a general guide as they do

not seem to match up from side to side. In this photo you can see the darker

line of the gap after the first super glue application. The second one is

visible and has not yet been sanded down. You can also see the small triangles

of plastic card on the lower intake and aft wing installed to replace voids.

The

next step was to attach the wings. These are not really molded to fit well. Even

after lots of trimming of the attachment holes and wing root itself to try to

conform to the curve of the fuselage, I was left with very large gaps. Super

glue was used to fill these once I got the wings somewhat even with each other.

Use the engraved attachment lines on the fuselage as a general guide as they do

not seem to match up from side to side. In this photo you can see the darker

line of the gap after the first super glue application. The second one is

visible and has not yet been sanded down. You can also see the small triangles

of plastic card on the lower intake and aft wing installed to replace voids.

Once that was done, the splitter plates were installed and the fit here left a great deal to be desired as well. Once those were installed and the first round of filler was sanded down, I lost interest in the kit and it sat for a couple of years.

Deciding that I really needed to finish up some of the many 'started but abandon' kits in my collection, I pulled this one out of the pile, blew the dust from the box and got back into it. The first thing I did was to see how much I had to go. For this purpose, a coat of primer was sprayed on the airframe so I could see what needed to be done. It wasn't pretty. I was less than jazzed about all the pinholes that had appeared on the underside of the fuselage so I applied more filler to this and several other parts. Once that was sanded down, I installed the tailplanes and the instrument panel section. Another coat of primer was applied followed by some aluminum.

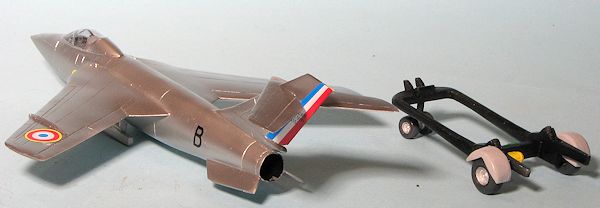

Boy, did that show up a myriad of glitches. The biggest of which was a very

rough surface. I broke out the 600 grit sandpaper and sanded the airframe as

smooth as I could without overdoing it. I also took this time to attach the

landing skids. The kit allows you to do these extended or retracted and has

separate bits for the main skids. After test fitting the airframe on the

trolley, I discovered that there was no way the aircraft would sit on it

properly. The kit maker provides no hold downs of any sort and it is sort of

like sitting a tube atop two tubes going crossways. Attaching the skids was a

bit tricky as well as the instructions are not very clear on how they go on,

even with the photos. The tail skid needs to be attached aft of the skid well.

There is an indentation on the front of the well for a much resined over pin to

fit, but if you do that you'll find it is too far forward.

Boy, did that show up a myriad of glitches. The biggest of which was a very

rough surface. I broke out the 600 grit sandpaper and sanded the airframe as

smooth as I could without overdoing it. I also took this time to attach the

landing skids. The kit allows you to do these extended or retracted and has

separate bits for the main skids. After test fitting the airframe on the

trolley, I discovered that there was no way the aircraft would sit on it

properly. The kit maker provides no hold downs of any sort and it is sort of

like sitting a tube atop two tubes going crossways. Attaching the skids was a

bit tricky as well as the instructions are not very clear on how they go on,

even with the photos. The tail skid needs to be attached aft of the skid well.

There is an indentation on the front of the well for a much resined over pin to

fit, but if you do that you'll find it is too far forward.

Meanwhile, I cut the lone canopy from its backing. It is nice that a form is provided for this as it makes cutting the canopy so much easier. It also allows you to make another if that is required. Since the framelines are so faint, I kept the canopy on the form to help me mask it. Test fitting it showed that it actually seems to fit rather well. I also painted up the bang seat. Two are provided, but both have air holes that are visible so I chose the one that was the least messed up.

I then applied yet another coat of primer to see how things looked. While not pretty, I was pretty fed up with filling air bubbles and voids so I went ahead and returned to the bench to add the seat and instrument panel decal. I also took the opportunity to finish building the handling trolley, even though I wasn't going to put the aircraft on it. The kit provides additional nose and main wheels along with additional front axles. This is so you can pick the best of the bunch, though none are without fault. All the wheels needed the axle holes drilled out.

| COLORS & MARKINGS |

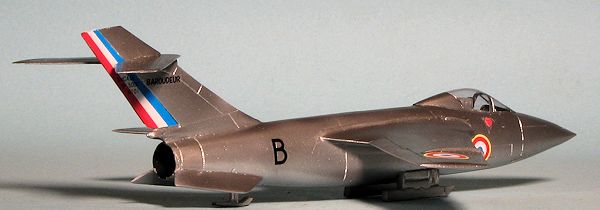

After installing the instrument panel decal and the bang seat, to which I added some tape belts, the canopy was attached with clear gloss paint and the airframe was again painted, but this time with Alclad II Dark Aluminum. This seems to give better coverage than the standard stuff for some reason. It was then repainted with regular Aluminum except for the area around the exhaust.

With that done, the decals were cut from the sheet and applied.

Their stick is fair, but to keep them in place, you do need to apply setting

solution as I had a few I thought were completely dry simply fall off when

handled. Fortunately, some extra roundels and plane names are provided. What is

missing is the script name for the nose and the fuselage letters. The photo

sheet shows that the planes were labeled B,T, and V. Though the font is not

exact, I picked a 20 inch B from a Modeldecal sheet for mine.

With that done, the decals were cut from the sheet and applied.

Their stick is fair, but to keep them in place, you do need to apply setting

solution as I had a few I thought were completely dry simply fall off when

handled. Fortunately, some extra roundels and plane names are provided. What is

missing is the script name for the nose and the fuselage letters. The photo

sheet shows that the planes were labeled B,T, and V. Though the font is not

exact, I picked a 20 inch B from a Modeldecal sheet for mine.

The handling trolley was built anyway, despite the fact that the aircraft will not rest on it properly. As with the rest of the kit the casting is not good with lots of air bubbles and pinholes and blobs of resin that had to be removed. As I was not planning on putting any real effort into this, I simply got it down to adequate. The kit provided multiple front wheels, rear wheels and front axle assemblies, none of which were particularly well done so I just chose the best of the lot. The wheels need to have the axle holes drilled. I painted the frame black with a green and yellow pressure bottle. The wheels were silver with the rest in Floquil's Weathered Black. I painted the fenders a light grey just to have some contrast.

| CONCLUSIONS |

It

is not often that I cannot recommend a kit and I am afraid that this one will

fit into that category for most modelers. It isn't that it cannot be built, as

you can see I managed to do so, it is just that it is so rife with molding

glitches as to make it as much an exercise in frustration as anything. It is

obvious that this kit is made by a guy in his home workshop. More modern resin

kits are allowed to cure in a pressure chamber that pretty well eliminates resin

bubbles and blobs from the parts. Every single part of this kit had molding

glitches and it almost resulted in the kit not being finished. In fact, had I

not given up on fixing the pin holes and air voids, it would still be in the

box. I can only recommend this to those who must have the subject in their

collection and have the skills and patience to make it look nice.

It

is not often that I cannot recommend a kit and I am afraid that this one will

fit into that category for most modelers. It isn't that it cannot be built, as

you can see I managed to do so, it is just that it is so rife with molding

glitches as to make it as much an exercise in frustration as anything. It is

obvious that this kit is made by a guy in his home workshop. More modern resin

kits are allowed to cure in a pressure chamber that pretty well eliminates resin

bubbles and blobs from the parts. Every single part of this kit had molding

glitches and it almost resulted in the kit not being finished. In fact, had I

not given up on fixing the pin holes and air voids, it would still be in the

box. I can only recommend this to those who must have the subject in their

collection and have the skills and patience to make it look nice.

| REFERENCES |

http://en.wikipedia.org/wiki/SNCASE_Baroudeur

May 2013

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.