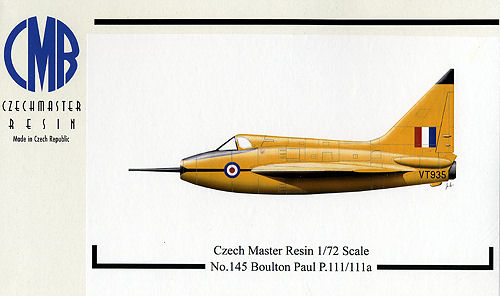

| KIT: | CMR 1/72 Boulton Paul P.111/111a |

| KIT #: | 145 |

| PRICE: | $ |

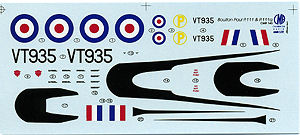

| DECALS: | One option |

| REVIEWER: | Scott Van Aken |

| NOTES: | Resin kit that builds one of three variants |

| HISTORY |

In the late 1940ís and early 1950ís the British aircraft industry was engaged in many projects to confirm and develop the design ideas captured from the Germans at the end of the second world war. As part of this activity the P111 was built for the Air Ministry to specification E.27/46 by Boulton Paul Aircraft Ltd to investigate the possibilities of the delta planform wing. It was also the first to be designed purely for research into the properties of the delta wing, as touted by Alexander Lippisch.

The P111 was designed to be the smallest airframe which could couple an engine, a Rolls-Royce Nene, an ejector seat (Martin Baker), and a delta wing. The latter could be fitted with a variety of extensions to investigate different tip profiles. The construction was all metal with the exception of the wing extensions which were of fiberglass.

The aircraft was not designed to be supersonic but to explore the characteristics of the aircraft shape in the transonic speed range.

The P.111 made its first flight on the 10 October 1950, at Boscombe Down with Squadron Leader Bob Smyth at the controls. Later test flying was carried out by the legendary test pilot, Alexander "Ben" Gunn, who described the aeroplane as "touchy" and "like flying a razors edge". The aircraft was extremely unstable longitudinally and could easily go into pilot induced oscillations. Because of this, and its bright colour scheme, the P.111 became known as the "Yellow Peril" - a pun on the nickname used for the Japanese threat during the war.

After a wheels-up landing the P.111 was modified to improve the flight characteristics, and re-appeared in its new guise as the P111a. In this guise, it flew again in July 1953. Airbrakes were found to be very effective but landing speeds were still very high. This was before aerodynamic braking, a technique that was used to help slow other delta aircraft such as the F-102 and Mirage III series. Still the addition of a braking parachute was deemed to be a requirement and the anti-spin chute was strengthened to be used in this manner.

After a last flight in 1958 it went to Cranfield. From there it was transferred to the Midlands Aircraft Preservation Society at Baginton, Coventry, where the P111a is currently exhibited. The P.111 was followed by the P.120 another delta-winged experimental craft.

| THE KIT |

Packaged in CMR's usual multi-compartmentalized bags, the kit provides the ability to do produce any of the different guises that were worn by VT 953 during her years of testing. What that means is that there are two different fuselages (

Packaged in CMR's usual multi-compartmentalized bags, the kit provides the ability to do produce any of the different guises that were worn by VT 953 during her years of testing. What that means is that there are two different fuselages ( one with and one without the fuselage mounted speed brakes), three different wings (each with different wing tips), two different canopies, two sets of gear doors, and two different ejection seats. There has never been as complete a kit of this aircraft as what CMR has produced for us here. It is almost a shame that they didn't include additional bits so one could build two of the planes as what would be needed is really minimal (like another interior, landing gear/wheels and fin)

one with and one without the fuselage mounted speed brakes), three different wings (each with different wing tips), two different canopies, two sets of gear doors, and two different ejection seats. There has never been as complete a kit of this aircraft as what CMR has produced for us here. It is almost a shame that they didn't include additional bits so one could build two of the planes as what would be needed is really minimal (like another interior, landing gear/wheels and fin)

In addition to the superbly cast resin, the landing gear are in either black injected plastic or are reinforced with wire. There is also a color photo-etch fret produced by Eduard specifically for this kit. What's the shame is the much of this fret is for the interior and the way the canopy is on this plane, little will be seen of the cockpit.

Instructions are superb and include full color information as well as a complete decal guide. A very nice touch is that the nose anti-glare panels are all duplicated on the decal sheet. Along with all this are four pages of very nicely reproduced photographs of the aircraft at the Midland Air Museum of the aircraft in its final guise (and with a clipped fin tip). These images should be a huge help in getting all the bits just right. Decals are superbly printed and quite thin so care does need to be taken when using them.

| CONCLUSIONS |

Czech Master Resin is probably the best resin kit maker in the Czech Republic and providing quality kits of interesting aircraft is one reason why they are so popular. This looks like another winner and a kit you can get with confidence that you are getting a quality product.

April 2007

My thanks to  Czech Master Resin for providing the review copy.

Czech Master Resin for providing the review copy.

If you would like your product reviewed fairly and quickly by asite that has over 350,000 visitors a month, please contactme or see other details in the