| KIT #: | R72-043 |

| PRICE: | $ |

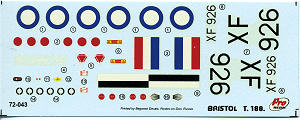

| DECALS: | One option |

| REVIEWER: | Scott Van Aken |

| NOTES: | Resin kit with vacuformed transparencies |

| HISTORY |

The aircraft had its genesis in the OR.330 contract for a high-speed reconnaissance aircraft, which eventually developed into the Avro 730. As the 730 was expected to operate at high speeds for extended periods of time, more data was needed on high-speed operations, leading to Operational Requirement ER.134T for a testbed capable of speeds greater than Mach 2. The aircraft was expected to run at these speeds for extended periods of time, allowing it to study kinetic heating effects on such an aircraft.

Several firms took interest in this very advanced specification and the eventual contract (6/Acft/10144) was awarded to Bristol Aircraft in February 1953.

Bristol gave the project the type number 188, of which three aircraft were to be built, one a pure test bed and the other two (constructor numbers 13518 and 13519) for flight testing. Under contract number KC/2M/04/CB.42(b) serial numbers XF923 and XF926 were given on 4 January 1954 to the two that would fly. To support the development of the Avro 730 Mach 2 reconnaissance bomber, another three aircraft were ordered (Serial Numbers XK429, XK434 and XK436). The order was cancelled when the Avro 730 programme was cancelled in 1957 as part of the review of defence spending. The advanced nature of the aircraft meant that 12% chromium stainless steel with a honeycomb centre was used for the construction of the outer skin, to which no paint was applied, but problems with the new Argon arc welding technique known as puddle welding caused long delays and was less than satisfactory. The W. G. Armstrong Whitworth company gave much technical help and support to Bristol during this period.

A quartz-lined windscreen and canopy and cockpit refrigeration system were designed and fitted but were never tested in the environment for which they had been designed.

Rolls-Royce engines were at first selected to power the 188, but five engine combinations were evaluated: two with Rolls Royce Avon 200s, two with the de Havilland Gyron Junior and one with an AJ.65, the last disintegrating on test. But the final choice for the 188 were two 10,000 lbf (44 kN) thrust Gyron Junior DGJ10Rs developing 14,000 lbf (62 kN) of thrust on reheat at sea level and 20,000 lbf (89 kN) at Mach 2 at 36,000 ft (11,000 m). Unfortunately this choice of powerplant resulted in the 188 having an endurance of only 25 minutes, which was too little time for any serious high speed research. Test pilot Godfrey Auty reported that while the 188 transitioned smoothly from subsonic to supersonic flight, the Gyron Junior engines were prone to surging beyond that speed, causing the aircraft to pitch and yaw.

Farnborough in May 1960 saw the first aircraft delivered for structural tests before moving on to RAE Bedford. XF923 undertook the first taxiing trials on 26 April 1961 but the first flight was not until 14 April 1962 due to problems encountered. XF926 had its first flight on 26 April 1963 managing to reach a speed of Mach 1.88 (2,300 km/h) at 36,000 ft (11,000 m). The longest subsonic Bristol 188 flight was only 48 minutes in length, requiring 70% of the fuel load to be expended to attain its operational altitude. The project suffered a number of problems; the main being - as mentioned above - that the fuel consumption of the engines didn't allow the aircraft to fly at high speeds long enough to evaluate the "thermal soaking" of the airframe, which was one of the main research areas it was built to investigate. Also, the takeoff speed was nearly 300 mph (480 km/h). Though it was eventually abandoned, the knowledge and technical information gained was put to some use for the future Concorde program. The inconclusive nature of the research into the use of stainless steel led to Concorde's being constructed from conventional aluminium alloys with a Mach limit of 2.2.

Experience gained with the Gyron Junior engine, which was the first British gas turbine designed for sustained supersonic operation, later assisted with the development of the Bristol (later Rolls Royce) Olympus 593 powerplant which was used on both Concorde and the BAC TSR-2.

In total the project cost £20 million. Various proposals to develop the 188 were considered including: ramjets, rockets, a fighter and reconnaissance variants. One serious proposal involved the fitting of "wedge" type intakes, but all development was terminated in 1964, the last flight of XF926 taking place on 12 January 1964.

| THE KIT |

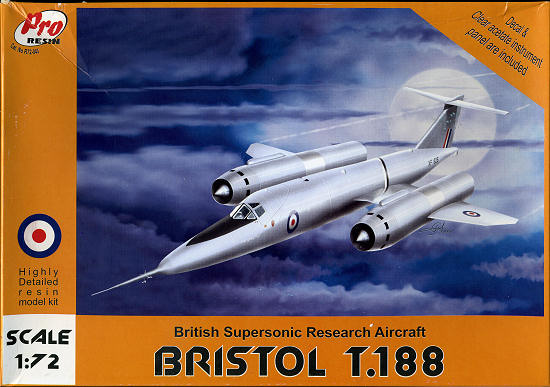

Pro Resin kits have a reputation for producing fine quality resin kits and this one has to be one of the largest they have yet molded. The long, thin fuselage has resulted in a four section fuselage with the break between the nose piece and the rest of it coming just a bit behind the nose wheel well door. Aside from two clear vacuformed transparencies, the entire kit is in resin. The short, stubby landing gear should be able to bear the weight of the kit without worries of deformation and while it may seem like no nose weight will be needed, some is noted in the instructions, though the exact amount is not.

Pro Resin kits have a reputation for producing fine quality resin kits and this one has to be one of the largest they have yet molded. The long, thin fuselage has resulted in a four section fuselage with the break between the nose piece and the rest of it coming just a bit behind the nose wheel well door. Aside from two clear vacuformed transparencies, the entire kit is in resin. The short, stubby landing gear should be able to bear the weight of the kit without worries of deformation and while it may seem like no nose weight will be needed, some is noted in the instructions, though the exact amount is not.

The cockpit is quite nicely done and rather complete. I fear that little will actually be seen though the somewhat small canopy windows. Each of the engines is four pieces with a left and right side, front and rear section. All of the flight surfaces are butt joined with large, smooth areas. I think that keeping these areas smooth is one reason the engines were split vertically. The speed brakes are quite interesting constructs that appear to pop out of the fuselage sides like a top hinged door more than like the usual. Each of the four speed brakes consists of four parts so one will be busy. In fact, this kit has a considerable number of small parts in the main gear assemblies so care and patience are the key with this one.

Instructions are a folded single sheet with parts layout and assembly drawings on one side, a history and painting/markings guide on the other. A variety of paint references are given so one is sure to find something locally. The aircraft is in overall polished stainless steel with markings for the extant aircraft, XF 926. The decals are quite nicely done and my experience with them has been positive. Only the black nose anti-glare panel will need to be painted by the modeler. The kit is really well detailed and I like that ProResin packs the 'dead space' in the box with Styrofoam pieces to help keep the parts from rattling around in transit.

| CONCLUSIONS |

This is only the second kit of this aircraft I have seen. The other is one of the 'bonus' models that came with the Anigrand 1/144 Valiant and that was to 1/144 scale. This one is a real beauty and if prototype or experimental aircraft are your forte, you'll have to add this one.

| REFERENCE |

May 2009

If you would like your product reviewed fairly and fairly quickly, please contact the editor or see other details in the Note to Contributors.